An interesting scenario arose recently at Performance Transmissions, where Rick was faced with a 62TE pressure control problem in a 3.6L 2019 Dodge Grand Caravan.

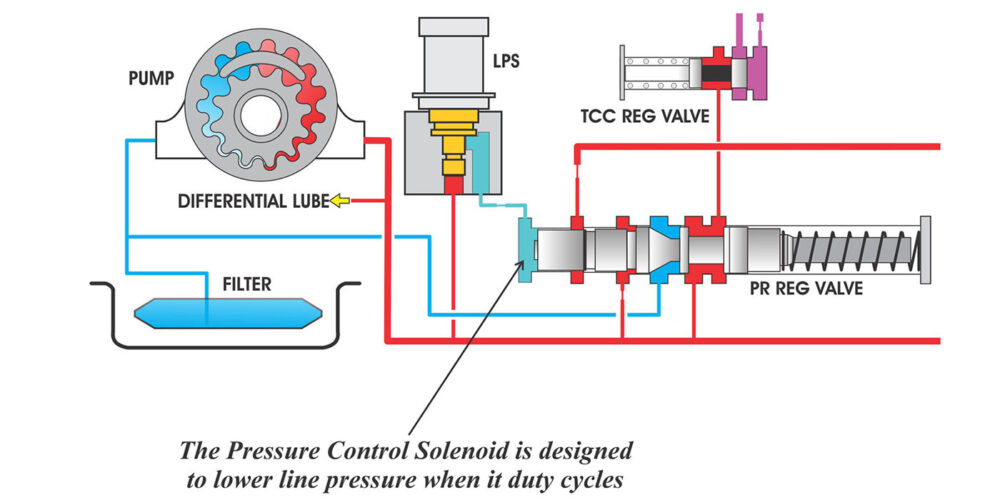

The Line Pressure Solenoid is a Normally Vented Solenoid designed to lower line pressure when it duty cycles as the hydraulics show in figure 1, above. The theory of operation provided by the manufacturer is as follows:

Line pressure is electronically controlled by the Transmission Control System and is measured by the Line Pressure Sensor (LPS). The desired line pressure is continuously being compared to the actual line pressure and is regulated by electronically changing the duty cycle of the Pressure Control Solenoid (PCS). (5% duty cycle = solenoid off = max line pressure; 62% duty cycle = solenoid on = min line pressure).

The Transmission Control System calculates the desired line pressure based on inputs from the transmission and engine. A calculated torque input to the transmission is used as the primary input of the desired line pressure calculation, and is called Torque Based Line Pressure. In addition, the line pressure is set to a preset level during shifts, and in Park and Neutral to ensure consistent shift quality.

The Line Pressure Sensor voltage is continuously monitored, and should always be between 0.35 and 4.75 volts. If it happens to be less than or equal to 0.35 of a volt for 0.18 seconds, it indicates a Line Pressure Sensor or wiring problem and will cause either DTC P0934 or P0935 to set. In Rick’s case, his vehicle set P0934 for Line Pressure Sensor Circuit Low. The possible causes the manufacturer suggests are:

- The 5-volt supply to the sensor is open or shorted to ground.

- The signal wire is open or shorted to ground.

- The sensor itself is bad.

- The PCM is bad.

With this information, Rick made the decision to replace the sensor with a new one made by the manufacturer. But it was to no avail. The problem remained.

Read more columns from our Shift Pointers series here.

He then checked the 5-volt supply and ground circuits to the sensor and verified that they were good. Next, he disconnected the alternator to see if this would stop the problem—but it did not.

With a gauge hooked up to the line tap, when the vehicle ran correctly, the gauge matched the scan tool. The sensor signal voltage matched what actual line pressure was doing. When it would malfunction, it would suddenly drop to 30 PSI. The scan tool didn’t make it clear enough if the computer commanded the Line Pressure Solenoid to drop line pressure, or if the solenoid itself was defective.

If it was defective, this made more sense as the computer would think something was wrong with the sensor seeing that it did not command line pressure to drop. With Rick’s shop being extremely busy, he decided to send this vehicle to his electrical man, thinking this may take some time to diagnose.

During his diagnosis, new codes appeared: P0222 for TPS 2 Circuit Low, a P0123 for TPS/APPS Signal Low and P2111 for an Electronic Throttle Control – Unable to Close. Rather than chasing down the cause to the P0934 code, this tech decided to look at the APPS.

With a scan tool he observed the APPS circuit voltages. This is when he saw the APPS 2 circuit become erratic intermittently. He then compared this to the line pressure signal voltage, discovering that they both occurred simultaneously.

No further diagnostics were performed at this time. The APPS (seen in Figure 2), was replaced with a new one (Figure 3).

Once it was replaced, he drove the vehicle long enough to prove that the correct repair was made to eliminate this problem. What is still left in the air is knowing how the APPS influenced the line pressure sensor signal. This will remain as A Peculiar Problem Syndrome (APPS). In the meantime, this can be categorized as a ”Silver Bullet Fix.”