Whether you are working on a 6L45, 50, 80 or 90, installing the center support that houses the L/R and 2-6 Brake clutches into the case can at times be difficult. In the past, I would grab the inside of the assembly with my fingertips on the friction teeth of the 2-6 clutch pack. I’d lift it up and bring it down into the case as perfectly as I could so it wouldn’t get cocked in the case. And if all went well, the L/R clutch would index and the assembly would slide right in. But then there were times when it needed to be jiggled around before it finally sat in place. By this time, I would have raw fingertips.

I thought to myself, there must be an easier way. It was when I was building a 4L60-E transmission that I discovered this easier way.

Here’s the step by step process:

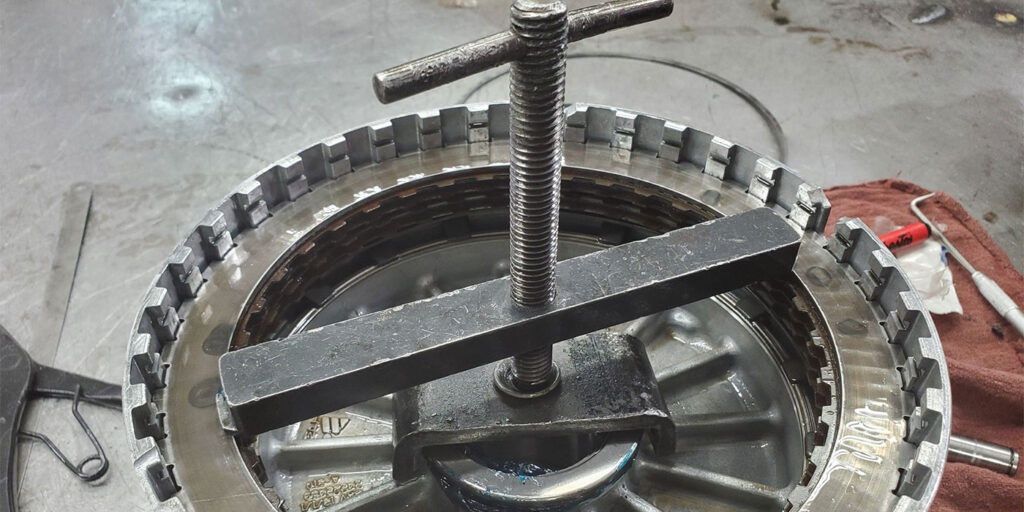

1) I use my L/R piston return spring compression tool to get the job done. I keep the top friction out of the assembly and sit the tool into the housing (figures 1 and 2).

2) I then put the pressure plate in over the top of the tool (figure 3). It fits perfectly.

3) I then put the snap ring in (figure 4) and screw the tool down securing the tool to the drum preventing it from wobbling (figure 5).

4) Lifting the assembly and putting it in place in the case has become a quick and easy process (figure 6).

5) Once in place, I remove the tool, install the friction plate, pressure plate and snap ring. Most shops already have the GM compression tool works with three- and four-speed transmissions. It now can be used with their six-speed transmission.

This article was contributed by Rick Hodgkinson, a rebuilder at AACTION Transmissions in Pembroke Pines, Florida.