Superior Transmission Parts, Inc.®

“We’re so proud,” says Dennis Erickson Jr., Vice President of the company his father founded, Superior Transmission Parts, Inc.® “We are a well-known industry brand name, and we are what we’ve always been, a family-owned leading-technology company that delivers parts of extreme high quality that are designed, tested and manufactured here in the USA.”

We are meeting in the lunchroom/lounge at the company’s headquarters in Tallahassee, Fla., a facility that houses production, packaging, sales and administrative functions. Most of the company’s research and development into kits, tools and parts take place in the nearby facility that, at one time many years ago, served as the firm’s headquarters.

Superior’s Global Sales Manager Robert “Bob” White explains that the company focuses a large amount of effort in analyzing common wear and failure points in transmissions and then develops solutions and innovative technologies that will address those concerns and enable rebuilders to have confidence in the longevity of the units they build. “Our fixes are for real problems; we are addressing real issues and we are living up to our motto: SUPERIOR SOLUTIONS – Technology That Works®. It comes from our passion for technology and improvement, the problem solving process that we prove works before it goes in a box! That’s why our customers and distributors rely on our processes put into the development and marketing of our products, so when they hit the shelves they know they are selling and installing confidence to their customers.

“We’re not just driven by the ‘need’ to be first to market with our products and solutions. While we maintain a project developmental timeline, regardless of how long it takes, we want to bring a finished, completed, tested and re-tested product to our customers.

So, after a kit has been developed and engineer-tested, we put it into several vehicle models and ensure it is real-world tested. We then know exactly how it performs and functions so when the end user installs the products he’s installing ‘Technology that Works’ and works above and beyond expectations. The 30 or so Top Ten Products awards we’ve received over the years proves this also. When users vote for your products and you win awards, it’s a very humbling experience,” White proclaims.

“On top of that, we’re monitoring the vehicle computer codes, looking for any unexpected effects a part may have on the network of sensors and computer controls. For instance, the PowerTow Performance® line is designed to be complementary with guys putting programmable controllers, uploading and flashing and changing shift timing or torque management settings. This is a huge thing in the industry right now, as some problems arise due to bad programming, corrupt files or even electrical wiring or component issues. You risk running into the most common issues if they are not taken into consideration during development of the instructions, like the recent electrolysis issues on the 5R110W ground cables from the battery to the block that melts and destroys pumps and converters.

We have added several “Tips and Tech” sheets to our instructions and many of our products have sections devoted to common build procedures and checking specs at the bench.

“Some of these symptoms can be based in wiring harnesses, battery cables or other electrical issues. Some come from the computer or sensors and can have their start in the ECM/PCM or mechatronic TCM, ABS or even electronic steering systems. This includes damaged connectors that fail or aren’t plugged in correctly or factory wiring that fails years later. Superior’s products have to take those issues into account and produce the desired results in the transmission system without creating something that causes a problem with the overall vehicle controls.”

White gives much of the credit over the past several years to the addition of Dean Mason’s TransLab Engineered®-branded products to the line. “Time after time, Dean’s technology is blowing everybody away. If you don’t do something to upgrade the unit, then the original weakness is going to be re-installed and it will end up right back in your lap as a warranty claim. We have, for instance, an upgraded snap ring that sells for $7. Guys weren’t spending the extra few dollars to upgrade that part so that after a few months, the ring would fail.

“On their warranty dime, the car is towed back in with a broken snap ring that has now caused $700 or $800 worth of gear-train damage. “I had a guy come up to me at a seminar thanking me for those critical snap rings and telling me, ‘I had my butt handed to me by a customer after we did a $2,400 rebuild. A week later, the car comes back on a hook. When we took it apart, sure enough, the snap ring had broken.’

“He explained to the customer that it was covered under warranty and that to make sure it didn’t happen again they’d installed our snap ring. The customer looked at him and asked, ‘So you’re telling me you charged $2,400 to rebuild my transmission and then saved $7 on a part that failed after a week leaving me stranded and in a rental car again?’

“The shop owner told me that the lesson was expensive but learned. He will no longer gamble with anything. Every unit now gets that ‘critical use’ snap ring.”

White continues by explaining, “It’s like our part #KO60 line pressure relief valve that is used on the 5R55N, S and W units. Superior’s founder, Dennis Sr., always said, ‘If you want to be successful, come up with problem-solving products like the KO60.’ It is one of the hottest things on the shelf. It sells itself.

“That’s the type of problem solvers we’re always on the quest for. In that tradition you have Dean’s TransLab Honda Kits. In the course of our research on that unit we discovered something that quite simply addressed all the overheating problems with the Honda four- and five-speed units. At one point, everybody thought that it was the replacement torque converter that was failing and causing the problem of overheating. Once solved, our patented P.R. valve would insure the underlying overheat problem would be addressed, and this not only saved the converter rebuilders’ warranty costs, many converter remanufacturers recommended our product, making our seven exclusive Honda/Acura kits, become the most highly-demanded ‘must use’ products for any Honda/Acura unit from late 1998-2011.

“Again, we have feedback at the seminars from guys who say they will not rebuild one of those Honda transmissions without using the Superior TransLab Engineered kit as part of that rebuild. And we discussed that the same components from that kit had eliminated having to open the units up again to address the secondary problem of sticking CPC valves.

“Consider how much labor time – labor cost – is being saved by this. Often, that additional labor time on a rebuild to address small issues like the sticking valve is something that doesn’t get consideration. A shop may be paying an R&R guy $25/hour and a builder whatever while charging $110/hour for labor. But when the builder or the R&R man are working for free to take care of that sticking valve or addressing a warranty issue, then that shop is losing $110/hour.

“This is a point we are always trying to make with builders and front counter sales staff. There is often a positive return from spending a few extra dollars on the parts used. We also see that the builders will be impressed by one of our products they see at a seminar, but the sales person back at the shop doesn’t understand the technical need to offer the upgrade or won’t sell it out of fear of the customer saying no. Sometimes a short explanation of the initial reason the unit failed will do, as most customers want to rely on the repairs they just paid good money for. I look at it as piece of mind.

“We keep educating that warranty work and extra rebuild labor aren’t free. Using Superior parts that we specifically develop to address issues shops are facing is almost always the lower total cost (parts + labor) option. We feel some shops aren’t understanding the full potential of savings that we’re presenting to their builders at seminars. It would be good to get shop owners and managers attending some of the seminars as well. Saving build and test time and avoiding comebacks are items that should be considered when comparing part options. Often it is our parts that provide value beyond the initial cost of that part and that end up being the lower total cost option for a complete repair, not just when it leaves the service bay for a few months. Being proactive, not reactive, is what makes for a good and profitable shop.”

And White tells that there are dozens of similar examples across the Superior product line. “The patent pending valve we’ve made for the 6R60/6R80 units allows you to fill it up without having to drive it for 45 minutes waiting for the fluid to get hot so that it can be checked for the proper level.

“Without our kit, you spend that time making sure that the customer doesn’t leave the shop driving on for a couple of hours (because a failed thermistor did not fully open) creating a two-and-a-half quart burp or air pocket of ATF while the unit melts down as the customer tries to limp it back to the shop. That one Superior product saves 45-50 minutes that would be necessary on every one of those jobs to guard against that failure. It’s a part that saves those 45 minutes and possible CB on every job due to low fluid operation. In some cases you should make sure the part is added whether you charge for it or not; it’s protection from a potential warranty issue or comeback and it pays for itself in the long run including the time it saves the shop.”

Erickson continues, saying, “For us there’s always the challenge of trying to address problems or shortfalls in a unit without having the vehicle computer overriding what we’re trying to do. Trying to stay on top of the demand for new solutions while working within the confines of what can be done without getting that override is what takes our focus, our time.

“We want to be first to market, but we insist on being right, on getting the complete and real fix. Insistence on being complete means we’re not always first. I mean when a transmission comes out we don’t just automatically add 10 parts to the line. We monitor the breakdowns and the problems that appear and then we set to work addressing those problems. This has always been our approach to the marketplace.

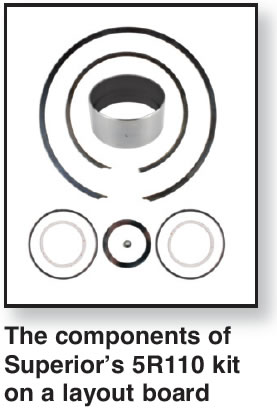

“Just because there’s a way of doing something doesn’t always mean there isn’t another simpler way to do it as well. With the 5R110 product, Dean discovered a solution for the PR valve that experiences wear because of oscillation that’s taking place. We have stopped the oscillation and have patents pending for the technology we used as this is something that can be used cross-platform for valve bodies experiencing similar wear.

“We are on the cusp of some cutting-edge technology with these valves. It’s a perfect solution for remanufacturers because even though it costs more for the original rebuild, it decreases the exposure from warranty claims so much that there’s actually a profit involved in using this technology.

“Many of our products add cost to the front end of a job in order to create savings of several times that magnitude on the back end, which comes from greatly decreasing the number of units coming back under the warranty program. Sometimes it’s frustrating to find that the bean counters don’t like that front-end cost, but we want them to realize that in order to end up right, you have to count all, not just some, of the beans.”

White says there is a vagueness to the definition of what parts and processes constitute a rebuild. It is something more of an art than a science as builders decide what parts to replace and which ones they can reuse. Sometimes it’s a general decision and sometimes it goes unit by unit, but it’s something that will vary from one builder to the next, from one shop to the next.

“This is where we need to reach out and better educate the shops as a whole,” he explains. “Our testing and retesting of upgraded parts that solve wear and failure issues in transmissions are products that should be considered for each and every applicable rebuild. Many Superior kits address problems so common that the kit should be used every time one of those units is built.

“Everyone at Superior wants you to know that our passion for research, testing and manufacturing goes beyond packaging and fulfillment. Our goal is to meet and exceed your demand for the highest quality, tested and re-tested products we put in every box. When a builder opens the box we want him to say to himself, ‘there’s that beautiful Superior kit that’s going to make this unit better than it was before!’”

Summing up, Erickson repeats, “We’re very proud of the people and the products that have and will continue to define Superior. More than anything else, we’re introducing and maintaining technology that works!”

Fairbanks

There’s a second well-known brand name that Superior takes to the marketplace. Fairbanks Racing Products was acquired by the company in 1998. GSM Robert “Bob” White says, “The Fairbanks Racing name was changed to Fairbanks Performance® to encompass cars and trucks for today’s enthusiast, the newer, PowerTow Performance® line is for towing, hauling and the performance diesel sector as well as gasoline powered pickups. Our product shows up in the entry-level, sportsman class of drag racing and truck pulls that are mostly dominated by diesel trucks. The line is also popular for building street rods and outlaw series vehicles.

“These Fairbanks products are the best-kept secret in the transmission industry,” White explains. The original Fairbanks TransAction® kits weren’t designed for the popular performance diesel trucks. I remember coming to Dennis and we discussed the need for a new Fairbanks line of truck transmission packages because nobody else had that product out in the marketplace. That’s where the PowerTow Performance line began. Something that’s gaining in popularity for diesel enthusiasts is the Dyno Shootout where they bring in a stand-alone dyno and put diesel trucks on it, as a way to compare speed and torque performance. A couple of Fairbanks Performance Products were in the trucks that won the shootout. When we get that kind of winning feedback, it makes us proud to know our products did the job they were designed to do! It’s a win-win for all of us!