“I don’t know of another shop that does nothing but transmission work that has 23 bays going,” says Marvin Gott, founder of Springfield, Missouri-based ACE Transmission. Add to Marvin’s description the fact that the bays are full, the lot is full of more vehicles and there’s a large ACE reman facility across town building units to support that 23-bay facility.

Gott says his transmission career began in the mid ‘70s when Dale England helped find him a job working at Springfield’s Economy Transmission retail. The shop owner, Bob Wehr, also had a remanufacturing operation (WEHRCO, later Aarons and subsequently acquired by ATC Reman) where Gott says he was borrowed by the reman operation for “a day or two,” to do teardown. That temporary assignment became permanent and Gott ended up floating, gaining experience working in warranties and dyno testing among other duties.

He says he had a shop at his home where he’d build transmissions for people on the side. “My father-in-law knew some people at Yellow Cab and the next thing I knew those people were asking me to work on their cars. A family friend owned a car lot and then we had the Buick dealership calling and then a little work from a Pontiac Cadillac dealership.

“I didn’t walk into my first shop totally blind. I had some people at my door when I was doing work on the side anyway. I liked Bob [Wehr], I really did. But I thought, ‘as long as I’m here, I, won’t ever get anywhere.’ So, I decided, ‘what the hell I’m going to try it.’ That was February of 1981 and 40 years later, here we are.

“I, basically I started out just doing retail, working 15 or 16 hours a day. When you’re a one-man operation, you spend your day talking to people on the phone and trying to build whatever you can. I’d often stay half the night and build something.

“Eventually I hired an R&R man and after we’d been in business two or three years, Darla [Gott’s wife] came in and started answering the phone and handling the office work so we could concentrate on building and installing.”

Gott says that a friend who rebuilt engines came to him wanting some carry out units built to put with his rebuilt engines, the beginning of a reman operation that has grown significantly over the years. According to Gott, the company moved a few times as it grew larger. He recalls that at one point, he was able to borrow some money, lease a former Oldsmobile/Honda dealership building and hire nine new people all in a two-week period. After that building was sold to a new owner, Gott again went shopping for a location, settling on the company’s current retail site. He says that the building had been a warehouse and that he and his retail sales manager, Charlie Tennison, cut out a wall and framed a new one that accommodated overhead doors over a period of four months to get up and running.

“We had six lifts on the front side of the building and our builders on the back side along with the dyno we used to test carry out units,” Gott recalls. Eventually the company outgrew even the expanded space and another building was added to the property. The new building contained offices and 12 bays to be used for R&R while the transmission building operation expanded to occupy the original building.

By this time, there were really two businesses going: the retail and the reman business. The reman facility built all the transmissions for the retail operation as well as reman units sold to other shops and businesses. Today, the reman business calls for a couple of ACE trailers that deliver transmissions and pick up core primarily in Missouri and Arkansas with some going to eastern areas of Kansas and Oklahoma as well.

In March of 2019, the remanufacturing operations found an expansive new home in a 52,00 square-foot building (See Transmission Digest April ’19). Taking the builders out of one of the buildings on the retail lot meant an expansion to a total of 23 bays available for R&R. Gott says that they can handle about 30 jobs a week; perhaps a few more.

“Charlie, the retail manager, is a very good salesman; he’s just good with people. I give him a hard time because there always seem to be about 80 vehicles on the lot,” Marvin says with a smile.

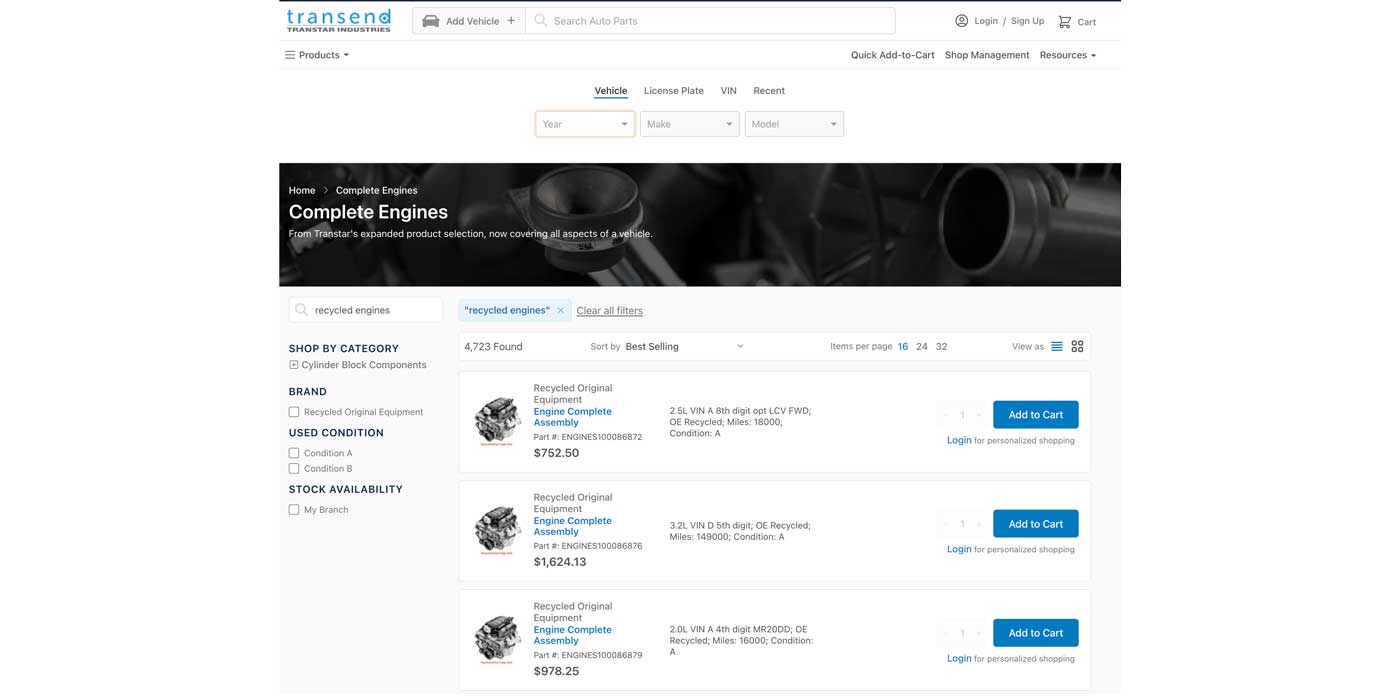

ACE started and continues as a family business. Gott’s son Daniel and Daniel’s wife Chelsie work with him and Darla and a staff numbering about 40 between the retail and remanufacturing operations. Gott says that another business strategy was learned from observing Bob Wehr’s operations. From the early days, Gott has stocked parts to sell other shops. “Sometimes we don’t get the job, but we sell the parts to the shop that did,” he reflects. The new reman facility contains a large parts area and counter where Transtar parts are available.

Daniel picks up the story by pointing out that ACE stocks an inventory of about 4,000 cores and a substantial inventory of remanufactured units on the shelf.

“We are building somewhere between 300 and 350 transmissions a month,” Daniel observes. “We have to do a few hot builds, but usually we have what we need in stock.” And while there is a substantial torque converter building area included in the reman building, Daniel notes that ACE converters are not sold to customers. “The converters we’re building either go with a remanufactured transmission we built or are used in the ACE retail shop.”

Daniel says that recently they have worked with a computer partner to develop remanufacturing software with capabilities beyond what’s been available. He says they built an optional retail module to accommodate the ACE business and that very soon, ACE and the software developer will be marketing the package to other remanufacturers.

The Gotts say that there’s room for the remanufacturing operation to grow much larger and they think they finally have all the space they need for future expansion. That’s a thought, however, that they’ve had before. All would agree that 40 years of increasing business and growth qualifies ACE Transmission as a success story.