It could be argued that modern alignment equipment has seen some of the most enjoyable advancements over any other automotive equipment in recent years. It has become so technician-friendly that many shops are providing no more than a five-minute crash course to new technicians coming in.

This makes it easy for seasoned technicians who are familiar with alignment theory, since any learning curve on new equipment is virtually eliminated. It also makes it easy for new technicians or those without alignment experience because the new equipment basically walks you through the entire alignment process.

The downside? Without core knowledge of alignment geometry and how it affects vehicle handling, you may not be able to properly diagnose steering-related issues or recognize them and tie them in with alignment readings.

So before we get into some of the features and benefits of new alignment equipment, we thought we’d run through a quick refresher on steering system geometry and alignment.

Steering system refresher

The steering system on a car, in the most obvious sense, simply gives the driver directional control of the vehicle. What’s important to remember is that the steering system, while quite often only thought of as the components that make it up, such as the tie rods, is functionally interrelated to all of the suspension angles on a vehicle.

The steering system is designed to work together with properly set alignment angles as well as built-in angles and suspensions design in order to provide the best directional control of the vehicle. When you perform an alignment, you are ensuring that the angles are correct for the particular vehicle you are working on, which in turn allows the suspension and steering to work together as designed.

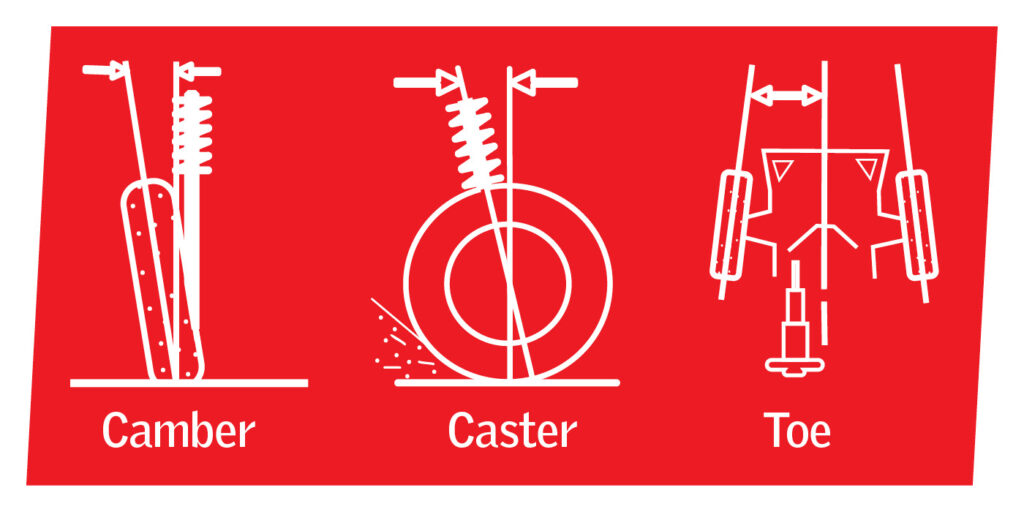

Camber is the inclination of the centerline of the wheel from a vertical position when viewed from the front. Camber is considered positive when the top of the wheel centerline tilts outward, negative when it tilts inward. Positive camber creates a natural turning tendency so a vehicle will tend to go toward the side with the most positive camber. Equal camber on each side causes any turning tendencies to oppose each other.

To picture this, think of rolling a wheel across the shop. If it is perfectly vertical, it will roll straight. If it tilts to one side or the other, it will roll in a circle in the direction in which it is tilted.

Not only will incorrect camber affect the directional tendency of the vehicle, but it will also cause tire wear on one side of the tread. The wider the tire, the more important it becomes to provide equal weight distribution across the tread of the tire with the correct camber setting.

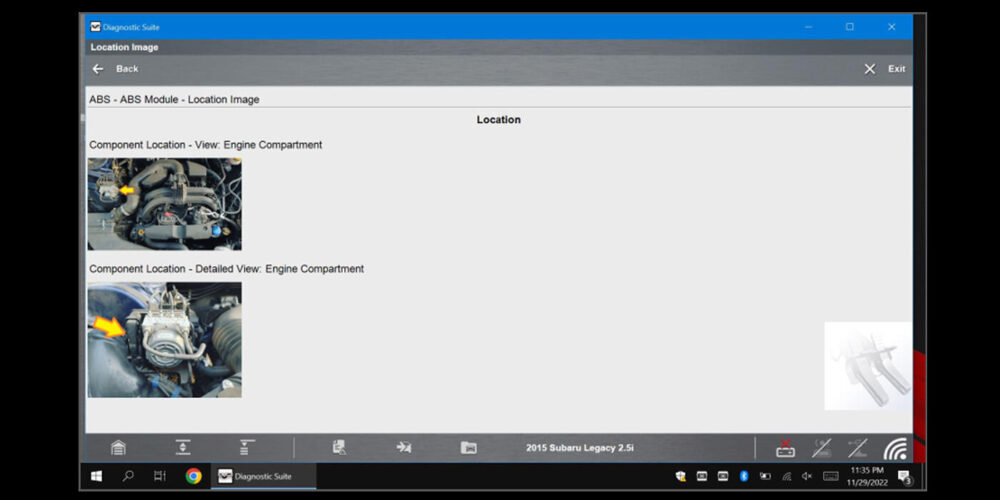

Caster is the angle between a vertical line drawn through the spindle and a line drawn through the steering axis. The steering axis line is best described as a line drawn through the upper and lower ball joints, or through the upper strut pivot and lower ball joint, depending on the type of suspension.

Positive caster is when the top of the steering axis tilts toward the rear of the vehicle and negative when it tilts toward the front. Caster can easily be the subject of a story of its own, but the most noticeable effects are with directional stability and steering effort. Rarely do we have to make caster adjustments on newer vehicles, but if the caster angle is incorrect, it’s time to look for bent components or possible collision damage.

Caster is not a tire wearing angle, but should not be ignored and vehicles that require a caster adjustment rely on it so all steering and suspension angles work together and make the vehicle handle as it was designed.

Toe is the difference in distance between the front and back of the tires. Toe-in is when the fronts of the tires are closer together than the backs. Generally speaking, slight toe-in is preferred because vehicles are aligned when they are stationary. While a vehicle is moving, dynamic loads on linkage components will cause a slight change in alignment angles, resulting in running toe that is different than the static setting.

A slight toe-in as a static setting will result in a zero running toe when the vehicle goes down the road and dynamic forces act on the steering. A zero or slight toe-in is best for running toe as toe-out will generally cause a vehicle to wander. Incorrect or excessive toe-in or toe-out will cause abnormal tire wear.

There are also a number of additional angles and measurements (perhaps a topic for another day) related to vehicle alignment and you may have heard of Steering Axis Inclination and Toe-Out on Turns. These are non-adjustable angles but when all other alignment specifications are correct, they will in turn be within specification. If not, look for bent components.

Modern alignment equipment

As technicians, regardless of the job, we are focused on quality and accuracy along with productivity. Older alignment equipment, some of which is still in service in many shops, is known for the amount of time it takes to make the initial setup and take measurements. It’s not uncommon for technicians to avoid the process and possibly not recommend profitable work as a result.

Modern equipment has taken setup times of 15 minutes or more and reduced them to two minutes or less. When you have new equipment that allows this type of productivity, technicians will be scrambling to recommend alignments, even just from a maintenance standpoint.

“Independent shops that are investing in modern alignment equipment are quickly realizing the profit potential that it offers.”

Quick mount wheel adapters are just one feature that has made setup much quicker with modern equipment. Automatic turn plates prevent a technician from having to manually remove the pins, barcode scanners make for quick vehicle identification, tire pressure stations automatically set the correct pressure and the technology of the cameras and targets is the crowning touch that makes setup and initial measurement a quick and easy process.

Even if you are only beginning to think about new alignment equipment, a recommendation from BendPak is to purchase an alignment lift as opposed to a standard four-post lift. An alignment lift, while functionally the same as a four-post lift for standard service, is designed differently with runways that are outfitted for turn plates. You can use an alignment lift just as a regular four-post and when you are ready to invest in the additional equipment, you already have what you need.

Armed with the core knowledge of alignment angles and the advantages of modern equipment, alignments can quickly become one of your most profitable general repair services.

Editor’s Note: This article initially appeared in TD’s sister publication, TechShop, and is being printed here as part of a series for transmission shops that offer general repair services.