Before the days of specialized transmission parts distributors, retail rebuilders in need of hard parts often sourced from local salvage yards. Today, retail rebuilders and full-scale remanufacturing companies can easily place bulk orders or conveniently shop online for their parts needs. Behind the scenes are organizations like Buffalo Engine Components (BEC) in Buffalo, N.Y. The company that started supplying engine cores and components in 1980 has become, the company says, “one of, if not the largest supplier of ‘good used’ and core transmission parts to the aftermarket.”

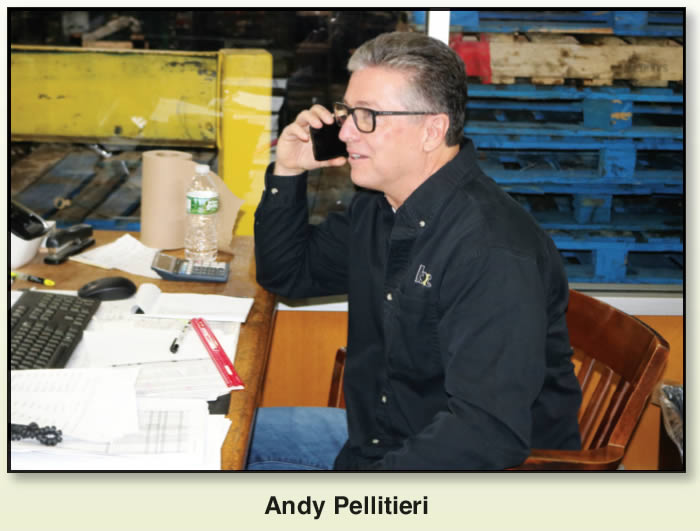

Founders Andy and Salvatore Pelliteri established Cousin’s Core Supply in 1980. In the late ’80s they started selling engines through a separate entity that they called Buffalo Engine Components, and by the early ’90’s the companies merged and were fully operating under BEC.

Jason Pelliteri says, “I joined the company in 1997 and my brother Joe came aboard in 2001. Salvatore retired in 2007 and before he retired, he and Andy made my brother and I partners. Now we’re all four equal owners and have grown to over 300,000 square foot of warehousing and close to 150 employees.

“Presently we sell engine and transmission cores and components to remanufacturers and parts distributors. We operate a full-line transmission-parts-distribution outlet, including a parts counter, for the local Buffalo-area shops. Our entire retail inventory is available for purchase on our website.

“To find the parts we need, we used to visit wrecking yards and pick only the units that contained those parts. Now we place one of our 250 roll-off containers in their yards, and the yard places engine, transmission and torque-converter cores into the container and calls for a swap when the container is full. How often we go depends on the yard. Some yards we visit three times a week, and others as little as a few times a year.

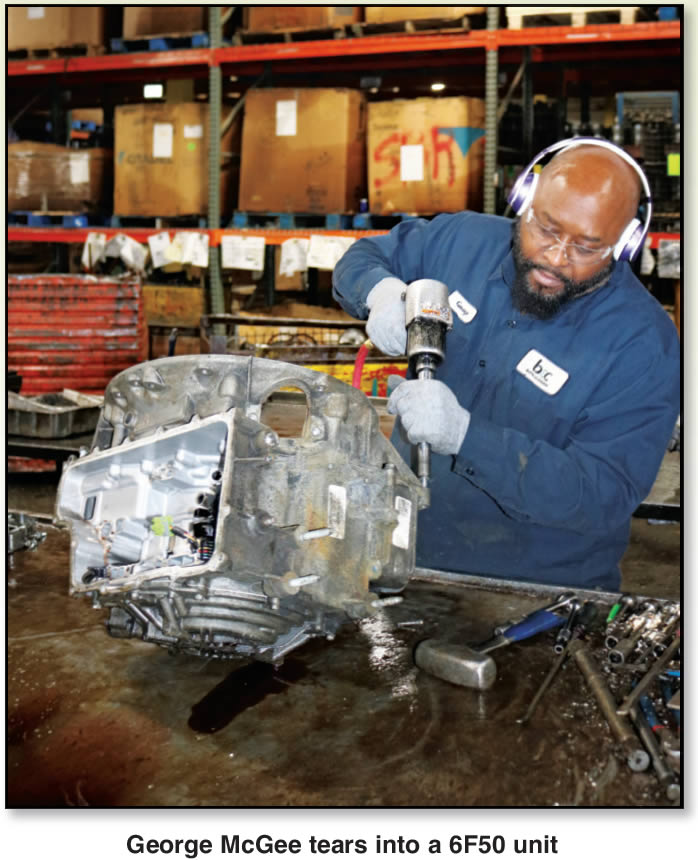

“Once the bins are full, BEC brings them back to our Buffalo location to be sorted. At that point, they determine whether the transmissions are sent to whole core or are to be directly processed for parts and scrap. We currently dismantle about 850 transmissions a day for parts and scrap, while the rest are sorted to the whole core inventory. We also process more than 400 engines per day and send them to our core inventory or to be scrapped.

“To handle all of the aluminum from our dismantling operation, we have two of our own aluminum melting furnaces at another location here in Buffalo. We run the furnaces five days a week, 24 hours a day. We produce close to 40 tractor-trailer loads of 2,000-pound sows (large aluminum or steel ingots) per month.”

Jason continues saying, “Many of our customers buy large quantities of ‘parts on the run’ to qualify and use for their own retail sales or production operations. We provide them a true on-the-run quantity of parts. By that I mean that any parts we disqualify for our own “good used” category do not find their way back into another customer’s order. If we won’t use it, we won’t sell it, so they are scrapped immediately.

“When transmissions get sent to teardown we run most common units in a mix because we can’t keep up with the quantity of units coming in order to strip them all in dedicated runs. Higher-end units and those with larger quantities of saved parts are usually processed in runs of 50 up to a few hundred.

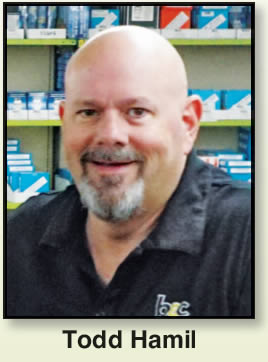

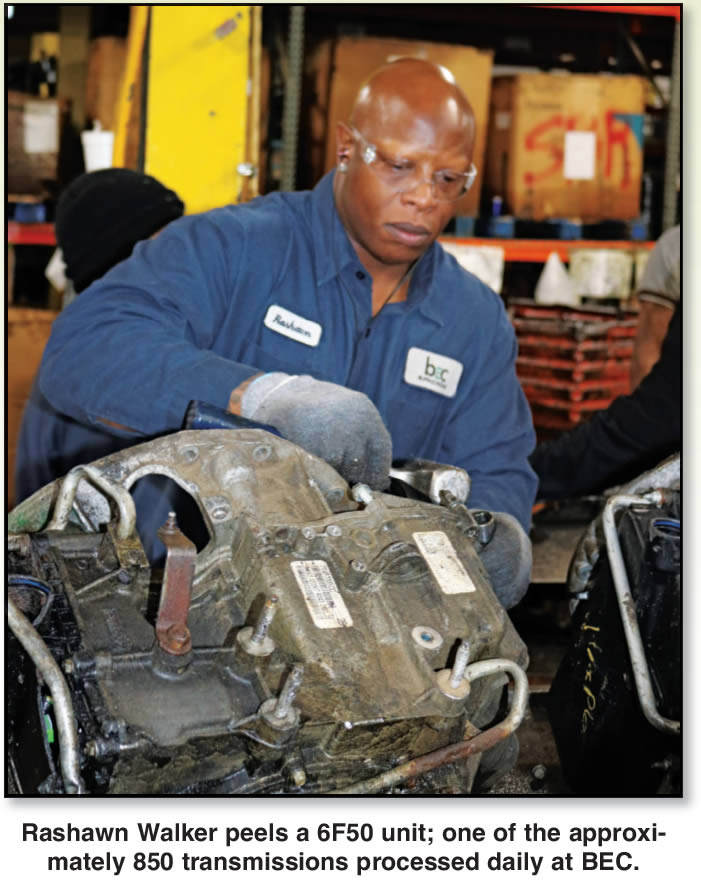

“Todd Hamil heads the transmission parts operations at BEC, he has over 30 years of experience in the industry. His transmission experience started at Tranzparts Wisconsin in Janesville, where he was the production manager and parts qualifier. Todd’s next stop was in Louisville where he was production and procurement manager for ATC and then Axiom. In 2006 Todd joined the team at Buffalo Engine Components and was a key member in the formation of our transmission parts department.

“Todd most often determines what and how many of each part needs to be saved based on what is selling and what is most likely to be the next part in line to fail. Most importantly we listen to the customers to make sure we have the right parts in inventory and what they expect to need in the future. On new units we may tear down 100 of something to salvage as many components as possible, then by the next run we have a better idea of what products sell. We can then adjust our teardown process to focus on the higher demand parts.

“It has been a trend recently for valve bodies and electronics to be the first parts to sell and a few years later, the parts wear issues start taking place and then its pumps or planets that are in demand. We constantly adjust our inventory to keep up with changes in demand. We want to be the first ones to have these new products available for the retail market.”

Todd explains, “We have 30 employees on our transmission teardown line, and another dozen loading the conveyors, taking away the scrap and qualifying the parts. It’s a busy operation. I provide the parts inspectors at the tear down with highlighted catalog photos when there are changes of which parts are to be saved from each unit.

“We have a few parts that get sent to our machine shops. For instance, some of our pumps get face-cut and the gears are tumbled. We may rebuild a planet set to get it back to OE specs. We sell valve body cores as ‘checked good used.’ We do an ohm test on solenoids and vacuum test the valve body. We offer over 300 individual valve bodies through our retail and web stores.”

Todd’s son, Nate Hamil, is the lead sales representative for the company’s retail transmission parts store. He started working at Buffalo Engine in 2010 as a parts sorter and delivery driver, and in 2014, he took on the sales role.

“Our sales staff will always go above and beyond to assist a customer,” says Nate. “If you are looking for a hard-to-find part that we don’t list, don’t hesitate to call and ask us. We have no problem searching our warehouse for the core you need or putting in a special order through one of our vendors for a part we do not stock.”

“I started doing inventory management while in the Army and was hired at Buffalo Engine after my discharge in 2014,” says Alicia Weatherbee. “At first, I managed the inventory and purchasing and eventually took the lead on the website relaunch. My main focus now is improving the website listings and functionality. We list everything we stock on the site, and the prices listed there are the same as if you were to call one of our sales staff. We ensure photographs are true to the part, and that we highlight any unique aspect of a given part.

“We want to be seen as a resource for retail customers and rebuilders across the industry,” Alicia continues. “The sales staff works to answer any of your product application questions, and I personally pull, pack, and ship any orders we receive. Online ordering is becoming increasingly popular with younger rebuilders and we hope they see our website and sales staff as a valuable resource in their purchasing process.”

Looking at the present and near-term future, Jason says that the growth area for parts reflects the vehicle purchase preferences of U.S. consumers. “Right this moment,” Jason says, “everybody is pushing CVT sets, and they are going out hundreds at a time. Who has more of those than us? We usually have 1,000 sets ready to go and we’re positioned to fill that demand.

“The car marketplace only lasts for so long. The vehicles depreciate and customers are less likely to continue major repairs on older cars. So, we can reduce our inventory as those parts are no longer in demand and rotate stock. If, on the other hand, you buy a truck or SUV, you’re more likely to keep the vehicle longer and put more money into repairs. We will continue to stock those products longer to match the longer lasting demand. Heavy-duty truck components are always in high demand.

“When it’s all said and done, our transmission parts business is about 80% truck and SUV and about 20% passenger car. That’s what the market wants and so that’s what we provide to the marketplace.”

Concluding, Jason observes, “Buffalo Engine Components continues to grow its ability to offer a large quantity of parts in whatever form the customer wishes to purchase them. The business continues its customer focus whether it be large quantities of ‘good used’ components, ‘on the run’ parts or offering our entire catalog, one piece at a time through an in-house website. Our attention to the changing demands of the customer and a sales staff that always puts that customer first puts BEC at the forefront of the transmission parts industry.”