Technically Speaking

- Subject: Redesign of internal parts to accommodate center-lube system

- Unit: GM 4L80-E

- Essential Reading: Rebuilder, Diagnostician

- Author: Wayne Colonna, ATSG, Transmission Digest Technical Editor

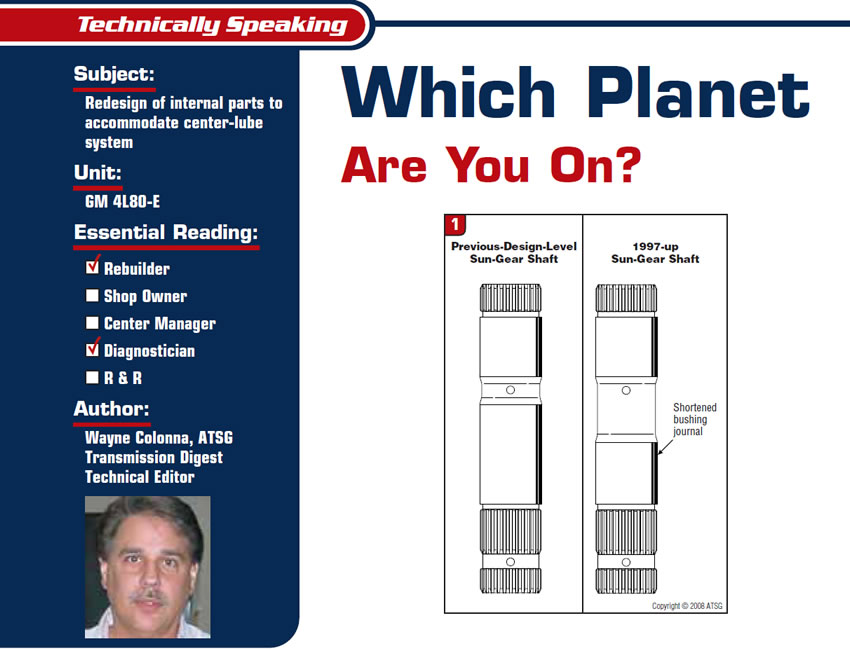

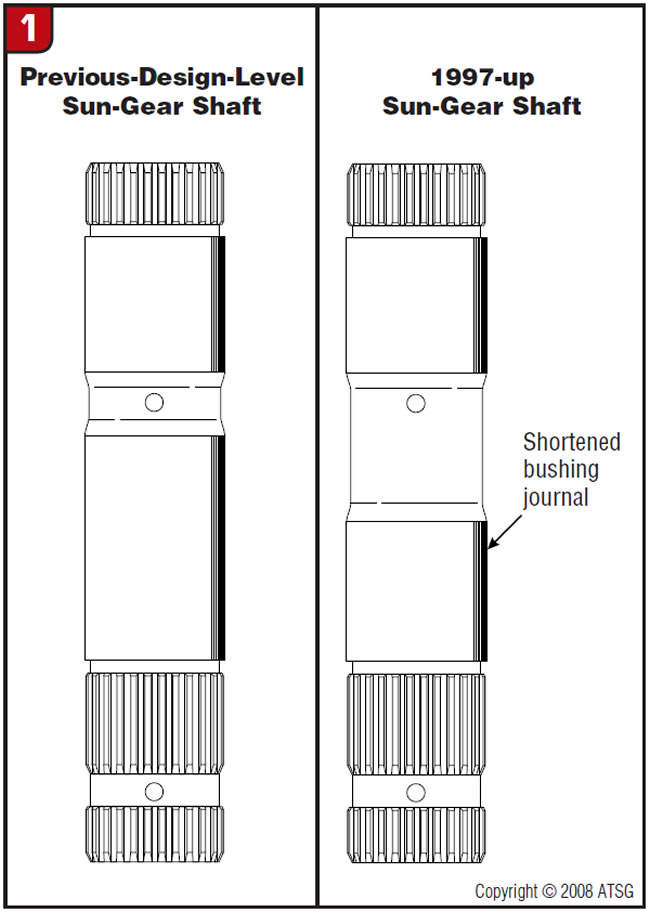

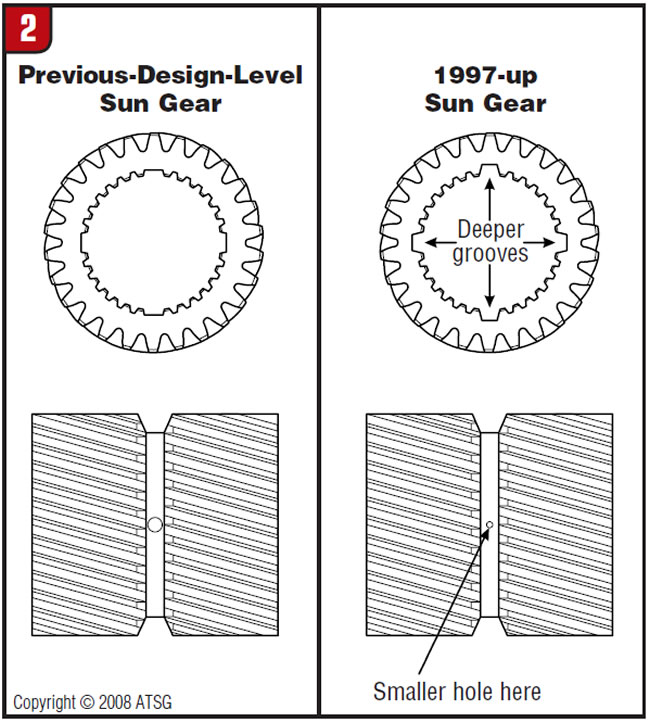

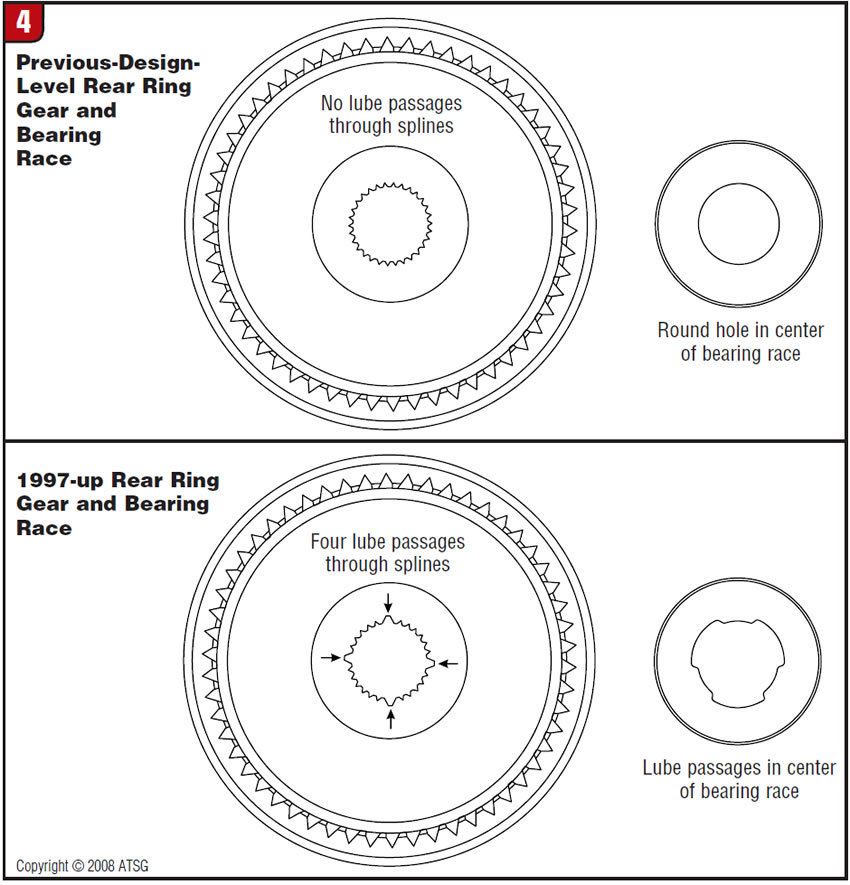

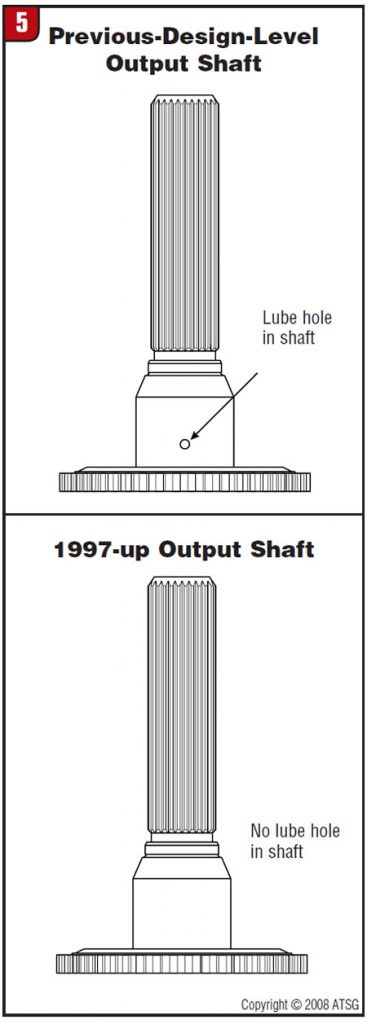

As most rebuilders know, in 1997 the 4L80-E went to a center-gearbox lubrication system by relocating the cooler return line from the pump to the center support. As a result, many internal hard parts were redesigned to accommodate this new lubrication system, as illustrated in figures 1 through 5 taken from an ATSG bulletin.

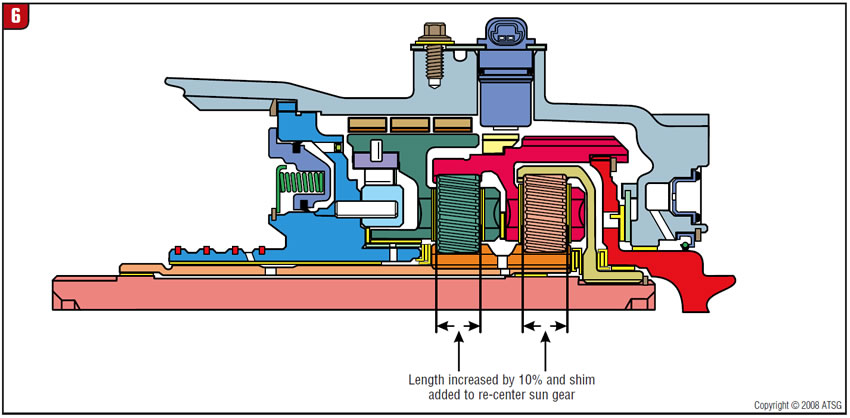

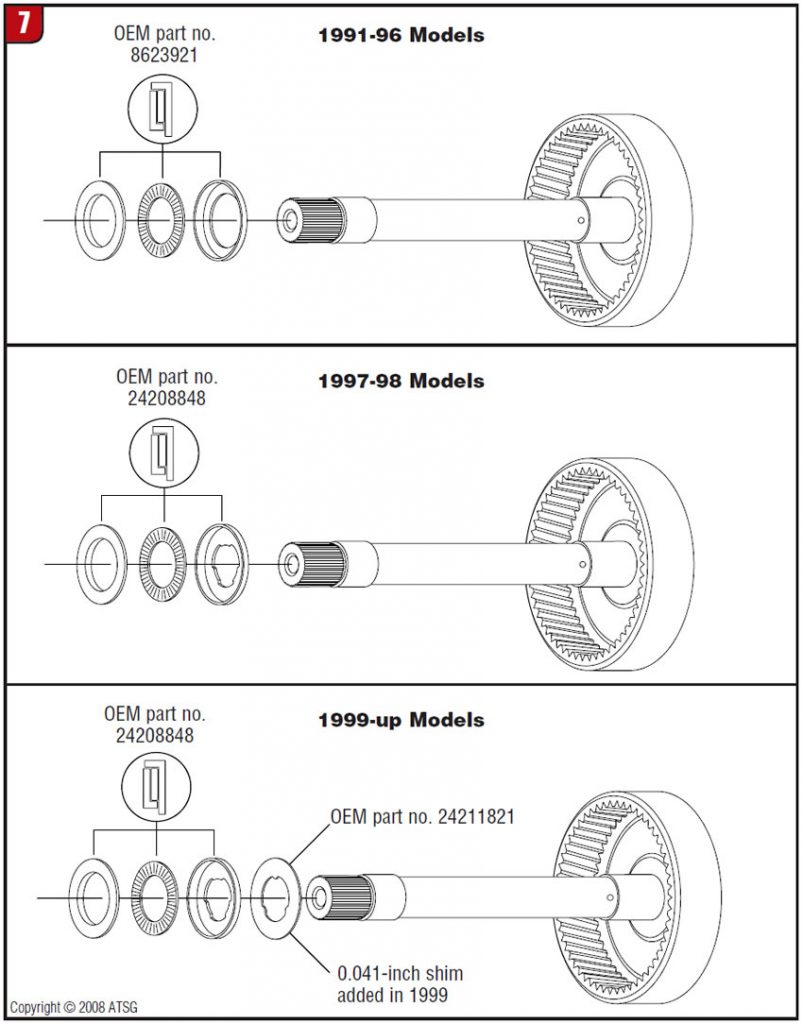

Then, in 1999, the planetary pinions for both front and rear carriers increased in thickness by 0.075 inch for increased durability (Figure 6). With the increased thickness of the pinion gears, the sun gear needed to be lifted by 0.041 inch so it could run centered in the thicker pinion gears.

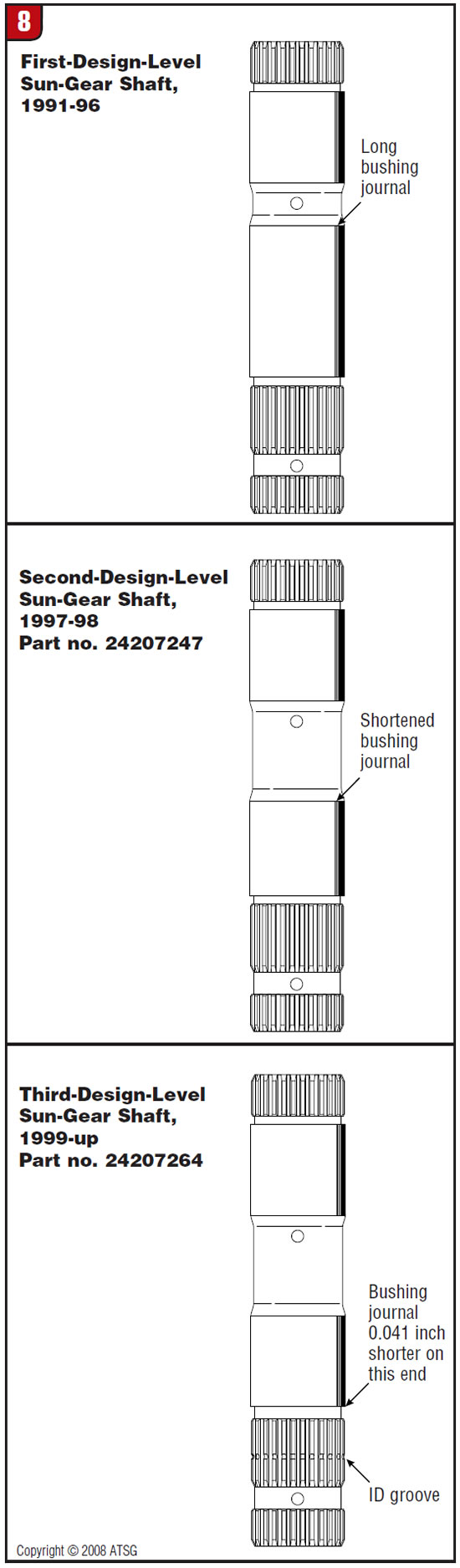

A 0.041-inch shim added between the thrust bearing and the rear internal ring gear gave the sun gear the lift it needed (Figure 7). The sun-gear shaft also changed to make room for this 0.041-inch lift (Figure 8). So now there are three different sun-gear shafts, with the second design being in use for only the 1997 and 1998 center-lube design.

It is imperative that you understand these part changes so that you use the correct parts when servicing this transmission. One example of using incorrect parts that often comes up can produce a stalling or stumbling of the engine when the shifter is placed into overdrive or reverse. This occurs when a non-center-lube sun-gear shaft is used in a center-lube system. The sun-gear shafts used in 1997 and later center-lube transmissions have a shortened bushing journal compared with the earlier design. Using the earlier-design shaft with the longer bushing journal will cause a restriction in the oil-cooler/lube circuit, producing increased pressure in the converter and making the clutch drag.

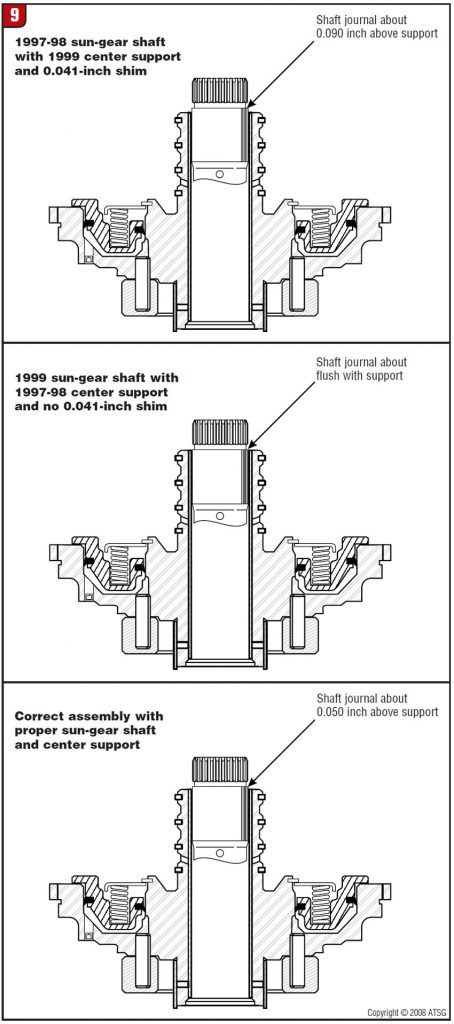

Another situation that occurs frequently is incorrect interchange of parts between first-design (1997-98) and second-design (1999 and up) center-lube units. This will cause a variety of different incorrect gear-train stack-ups. One example is using a 1997-98 sun-gear shaft with 1999 and later parts. This will cause the sun-gear shaft’s bushing journal to protrude above the bushing by nearly 0.90 inch (Figure 9). If the opposite occurs (1999 sun-gear shaft with 1997-98 parts), the bushing journal is nearly flush (Figure 9). When all the correct parts are used, the bushing journal should protrude above the bushing by about 0.050 inch, also shown in Figure 9.

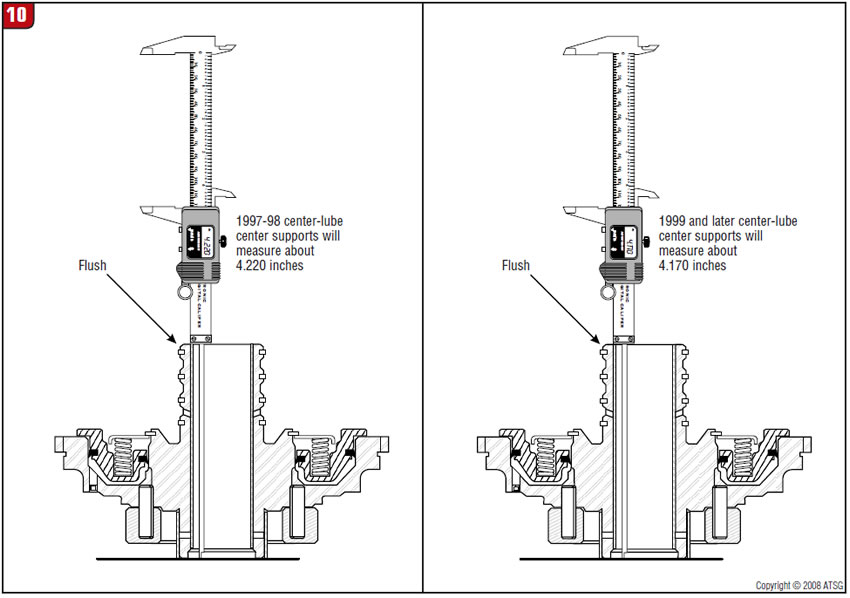

Similar problems can occur if an incorrect center support or rear planetary carrier is used. Figure 10 shows how to distinguish 1997-98 center-lube center supports from 1999 and later supports. As you will see, there is a difference in height of about 0.050 inch between the two. But when it comes to the rear planetary carrier, determining the correct use requires attention to a small but very important detail.

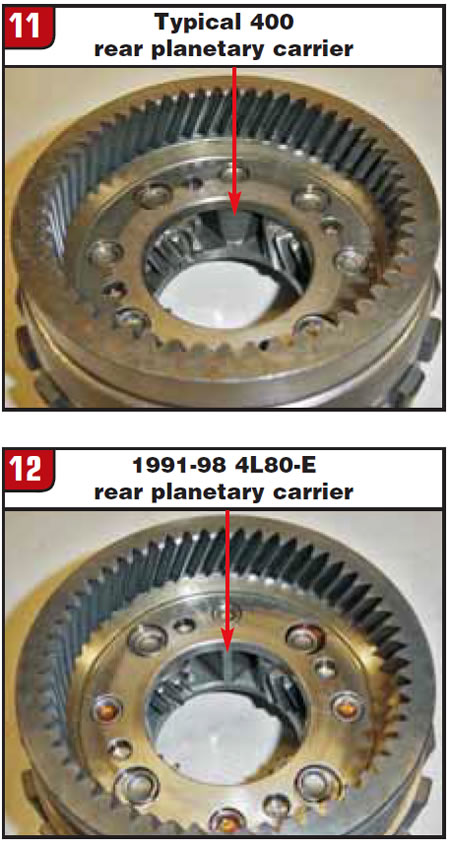

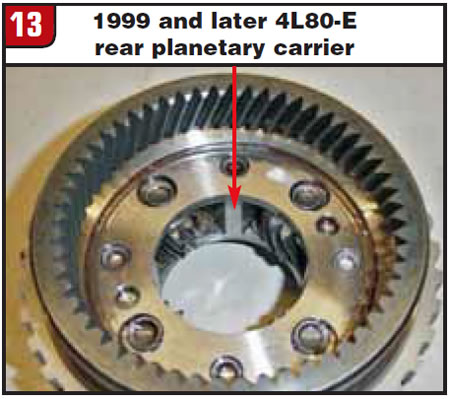

As mentioned at the beginning of this article, in 1999 the planetary pinions for both front and rear carriers increased in thickness by 0.075 inch for durability reasons. The original pinion-gear thickness is about 0.710 inch, which changed to 0.785 inch for 1999 and later carriers. The front carrier pinions can be easily measured with a micrometer for thickness verification. The rear carrier is a bit more difficult. The easiest way, as I said, is by observing a small but very important detail. By simply looking at the carrier design between the pinion gears (figures 11, 12 and 13) you can quickly see the differences between a typical 400 rear carrier, a 1991-98 4L80-E carrier and the 1999 and later rear carriers. With these side-by-side comparisons, the differences speak for themselves.

With all these subtle differences dimensionally, you can see how easy it is to use incorrect parts and the various possibilities in clearance problems they can produce. They could cause too much, or maybe not enough, gearbox space. So make sure you know which planet you are on and prevent yourself from being lost in space or outer (out of) space!

Many thanks to the good folks at Hardparts For Transmissions, who shared their knowledge and pictures of the carriers used in this article.