Up To Standards

- Author: Mike Weinberg, Contributing Editor

There is an epidemic of comebacks, failed diagnosis, wasted labor, early baldness, premature gray hair and increased phone traffic to the suicide hotlines in our industry. A great percentage of the problems are generated from dealing with the late-model electronically controlled transfer cases.

About 75% of the technical calls we handle are dealing with transfer-case problems, usually occurring after a transfer case has been disassembled and repaired, or another reman or new unit installed. The conversations range from, “I took the transfer case apart and can’t find anything wrong with it” to “This is the third transfer case we put in the vehicle and I still have the problem,” or “The reman transfer case I just bought from you is doing the same thing.”

This article will be a step back to basics to prioritize the steps that must be taken in a specific order to ensure a successful resolution of the customer’s concern.

A transfer case in any form is simply a power divider. It bolts to the transmission and is capable of dividing power between the front and rear axles when in four-wheel-drive mode. The sophistication of the transfer case has increased at the same rate as the price tags for the vehicles in which they are included. It is very common to find SUVs in today’s market with $50,000 window stickers. Maybe you younger people aren’t impressed with this, but for a guy my age, whose first house was $33,500 and sat on a half-acre lot in a good neighborhood, it is a lot of money.

The manufacturers know that they cannot sell such a vehicle unless it has the appropriate number of bells and whistles attached to it. So we now have very sophisticated four-wheel-drive or all-wheel-drive cars and trucks that use electronically managed transfer cases to, in many instances, automatically engage four-wheel-drive capability without the driver’s input. These same vehicles also have ABS, stability control and traction control, all of which are tied in to the transfer case and transmission as a set of related systems.

Looking at the entire vehicle as a group of complicated systems that are all dependent on each other for proper operation poses the question, “Do I wish to work from the outside in or from the inside out?” Working from the inside out is expensive and creates many wasted hours as the technician struggles to start from the most-labor-intensive job (removal of the transfer case) as opposed to working from the outside in, where logic states that you will work on all exterior possible causes before you take anything major apart.

Working from the outside in is the only correct path in any diagnostic routine that does not involve obvious mechanical damage. If the unit is drivable but the customer has concerns generated by flashing lights, codes set or chatter, shudder, bind-up, or other symptoms of less-than-correct operation, you must begin work “in an orderly, proficient, military manner” – in other words, a game plan, one that you will follow step by step on every occasion.

The “shotgun approach” is a sure way to going broke. We sell about 50 reman transfer cases a week, of which 35 or so are electronically controlled units. Of those 35 electronic transfer cases, about 25% of the cores that are returned have little or nothing wrong with them. This means that the shop performed a lot of work without addressing the cause of the customer’s complaint and used the tech line to complete the diagnosis after the fact. The last order of business should be removing a unit from a vehicle after all diagnostic routines are complete and there is no outside component that can be causing the complaint.

The first step in your game plan will be to arm yourself with the correct tools and equipment for the diagnosis. This means obtaining access to the factory repair manuals and proper diagnostic tools, scan tools, ohmmeters etc. Many of these late-model transfer cases are capable of setting well over a hundred codes. You must get hold of the factory diagnostic routines, fault codes, pin-point checks and theory of operation. Most of the factories are making this available on disc or by download from a Web site. If understanding all the design parameters of the component involves 150 to 200 pages of material, why would you try to fix such a complex item with absolutely no knowledge? If you do not know what readings you should be getting on your scan tool or ohmmeter, why bother hooking it up? You need to access the books and have a concrete approach to the diagnosis.

The second step in the basic commonsense approach is to understand the role tires play in the operation of the transfer case. All electronic transfer cases that can automatically divide power between the axles are sensitive to wheel speed. When the computer sees a difference in wheel speed it begins to actuate the automatic four-wheel-drive components, because the computer interprets a difference in wheel speed as a slip.

What if the difference in wheel speed is not due to actual slippage but you have a difference in tire size resulting from wear, mixed sizes or incorrect pressure? The computer does not differentiate; it interprets any difference in wheel speed as a slip because no matter how sophisticated the memory system is it cannot think!

What would happen if you had a transfer case in a vehicle with the differential ratio on the rear axle not matched to the front-axle ratio? The transfer case would go into a bind after a certain number of wheel revolutions, would bang or chatter as the bind was released in the internal transfer-case components, and then it would go into a bind again, in an endless cycle until either something broke or the axle ratios were corrected. This is the same thing that happens when tire sizes differ because of mismatches or unequal wear. There will be bind-up and crow hop going around turns, codes will be set, there will be clutch slip and chatter, and there is NOTHING wrong in the transfer case.

GM has a technical bulletin out on the 136, 236 and 246 series of electronically controlled transfer cases that I will quote as part of the routine here. These transfer cases operating in the auto mode may exhibit a vibration/shudder during low-speed turns such as a parking-lot maneuver at speeds up to about 5 mph.

Recommendation/instructions: Drive the vehicle a minimum of five miles to obtain operating temperature. Once at operating temperature, drive the vehicle into a tight turn just short of the steering-wheel lock/stop at a speed of less than 5 mph. If the shudder is present, perform the following diagnostics.

1 – Remove the TCCM fuse and see whether the condition is gone. If the condition is gone, proceed to step 2; if the condition is unchanged, skip to step 4.

2 – If the condition is gone, begin by performing a rolling tire-circumference test:

Mark all four tires at the 6 o’clock position

Drive the vehicle forward in a straight line for 10 tire revolutions

After 10 revolutions, if any tire is off from the 6 o’clock position by more than 1 inch the tires should be replaced as necessary.

Now I interrupt this bulletin for the purpose of further examination of what you just read. If you have a tire that is 30 inches in diameter, for round numbers, and you remember your high-school geometry, you multiply 30 inches by 3.14 (pi) to get the circumference of the tire. 30 x 3.14 = a tire circumference of 94.20 inches. Dividing this number by 12 inches gives you a circumference of 7.85 feet. Driving the vehicle 10 revolutions of the tire means the vehicle will travel 78.5 feet. If the marked positions on the tires are off by more than 1 inch in a travel of 78.5 feet, how sensitive are these systems?

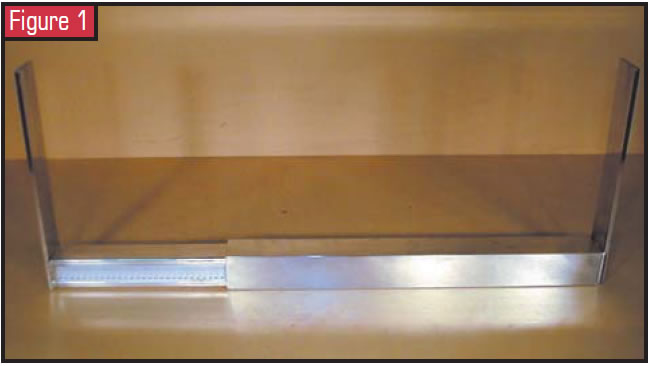

Now there is a quicker way to measure tires, by using a stagger gauge. A stagger gauge (see Figure 1) is a large caliper that you can put across the diameter of the tire (see Figure 2) to obtain a direct reading of tire circumference (see Figure 3). Remember that you are not reading diameter; you are reading the tire circumference. This is quick, is a one-man job and does not require an 80-foot driveway, and you don’t have to put the car on a lift and use a tape measure around the center of the tread (see Figure 4).

Before you go any further, it is important to note that tire pressures and sizes are the No. 1 cause of complaints and codes with automatic computer-controlled transfer cases. A difference of 1⁄16 inch in tread wear is enough to set some codes, and when you measure the tires with a stagger gauge all must be within 1⁄4 inch in circumference, and all the pressures must be the same. This is a step in your game plan that will cut a lot of waste from your budget. Never do anything with one of these transfer cases without confirming the tire sizes and pressures.

Now, back to the bulletin:

3 – If removing the TCCM fuse corrects the condition and the rolling tire-circumference test indicates that the tires are within specifications, proceed with the following:

NVG136 – Inspect the TCCM for module numbers and replace as required: 98-01 Olds Bravada, 15748801; ’99-01 Chevrolet Astro and GMC Safari, 15748744.

NVG236 – Inspect the TCCM for module part # 15748800 and replace as required – ’99-01 Chevrolet Blazer and S10; GMC Envoy, Jimmy and Sonoma.

NVG 246 – Inspection of the TCCM is not required – ’99-01 Escalade, Silverado, Tahoe, Sierra, Yukon, Yukon XL

4 – If the shudder was not eliminated by removing the ATC/TCCM fuse, remove the encoder motor from the transfer case and test-drive the vehicle again at operating temperature.

If the shudder is eliminated, replace the encoder motor.

If the shudder was not eliminated, re-install the encoder motor and fuse, verify that the shudder is still present and remove the front prop shaft.

Drive the vehicle at operating temperature with the front prop shaft removed; if the condition is still present and the vehicle is equipped with a G80 locking differential, the axle fluid should be changed and the vehicle driven in several left- and right-hand circles, then driven at least 50 miles under normal driving to remove any glazing from the differential clutches.

This bulletin, Document #1389723 (P101409), then goes on to address further internal repairs to the transfer-case clutch pack if all the external items discussed pass their tests. It also discusses changing the transfer-case fluid before internal inspection.

So, to recap, we have to test tire sizes and pressures, the encoder motor, the TCCM module for updated versions, the rear-differential posi clutches and fluid, and the transfer-case fluid before we ever think about going inside the transfer case. The inside-out approach, although it works in your golf swing, will have you removing a transfer case, disassembling and attempting a repair, re-installing the transfer case, and then doing all the previously mentioned steps to solve the problem.

Think about the significance of properly matched tires and how many wheel-speed-sensitive systems there are on the modern vehicle. If the tires are wrong, it affects the transmission/transfer case, the antilock-braking system, the traction-control system, the differentials and possibly the stability control. Before you leap into the unit, take a look at where the rubber meets the road.