Up to Standards

- Author: Mike Weinberg, Contributing Editor

The expansion of technology is never ending, and the sophistication of the new models being produced by the world’s automakers keeps increasing. The demands from the consumer for better-performing vehicles has engineers all over the world scrambling to create more-advanced designs. The growth in sport/utility vehicles continues, and there is an influx of so-called “crossover vehicles,” which are built on a passenger-car design that features all-wheel-drive capability for safety, performance and all-season use.

As you would expect, the growth in transfer cases to equip these vehicles is very strong, and the designs are becoming more complex. The transfer case as a unit is still a relatively simple power divider, but the complexity and sophistication show up in the computer control and electronics involved in meshing the transfer case with electronic engine-management systems, computer-controlled transmissions, antilock brakes, active suspension, stability control, traction control etc. that are now the cutting edge of automobile design.

There are probably about 30 pages in a service manual devoted to rebuilding a transfer case and about 150 pages to the diagnostic and troubleshooting routines necessary to diagnose these interconnected systems. Gone forever are the days when the manufacturers built vehicles that had the driver exiting the vehicle to lock front hubs and required shift levers to engage the ranges of the transfer case. Soccer moms and high sticker prices have forced the engineers to create vehicles that switch from two-wheel drive to four-wheel drive without the driver’s input.

New Venture Gear is a major supplier of transfer cases to the world’s automakers. A subsidiary of DaimlerChrysler, New Venture Gear began life as a marriage of the New Process Gear division of Chrysler Corp. joining with the Muncie transmission division of GM to manufacture transmissions and transfer cases. That joint venture has now been dissolved, with DaimlerChrysler retaining the New Venture name and continuing to design and manufacture transfer cases at its plant in East Syracuse, N.Y.

The thrust of this article is to help you understand the variety and function of the new models of transfer cases you will be asked to repair and to help you in identifying which units you are working on. You can’t tell the players without a score card.

New Venture Gear classifies its transfer cases into four systems of operation:

- Active on-demand 4WD operation – The computer monitors the front and rear axles’ speeds and interprets any speed difference as a loss of traction. At that point the computer signals the transfer-case clutch pack to engage, and power is distributed to the axle that needs it until both axles are again at the same speed. This operation takes place without any input from the driver.

- Progressive on-demand 4WD operation – In this mode the vehicle operates in 2WD. When one or more of the driving wheels lose traction, power is transferred to the other wheels without any driver involvement. In these systems the driver is usually unaware of the 4WD operation.

- Full-time 4WD operation – This system distributes power to both the front and rear axles any time the vehicle is in operation.

- Part-time 4WD operation – These transfer cases operate in 2WD normally, and the driver must shift into 4WD manually to engage both axles. These shifts can be done “on the fly” – without stopping – through the use of synchronizers.

Classification of transfer cases by operating system:

- Active on-demand – NV 126, NV 136, NV 226, NV 236, NV 246

- Progressive on-demand – NV 247

- Full-time – NV 124, NV 125, NV 149AWD, NV249

- Full-time plus part time – NV 242, NV 242HD, NV 242 HD AMG (Hummer)

- Part-time – NV 231, NV 231 HD, NV 241, NV 241, NV 241HD, NV 243 (electric shift), NV 261, NV 261HD, NV261SHD, NV 263HD (electric shift), NV 263 SHD (electric shift), NV 271, NV 273 (electric shift).

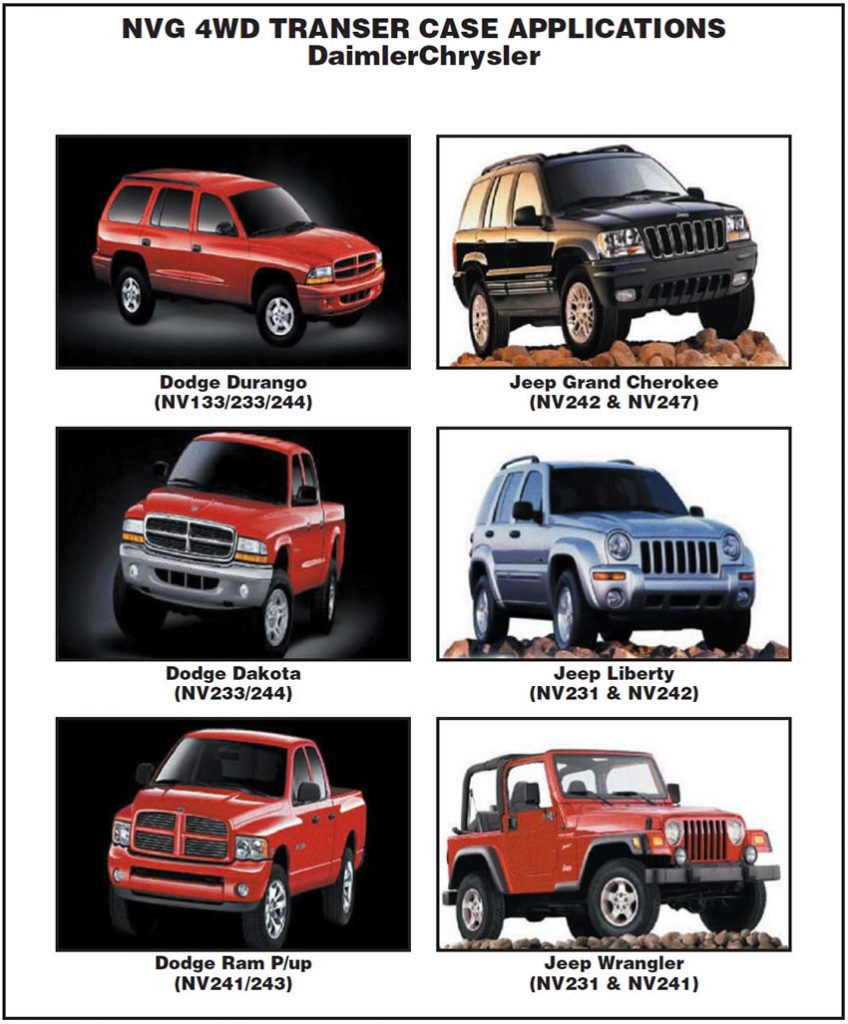

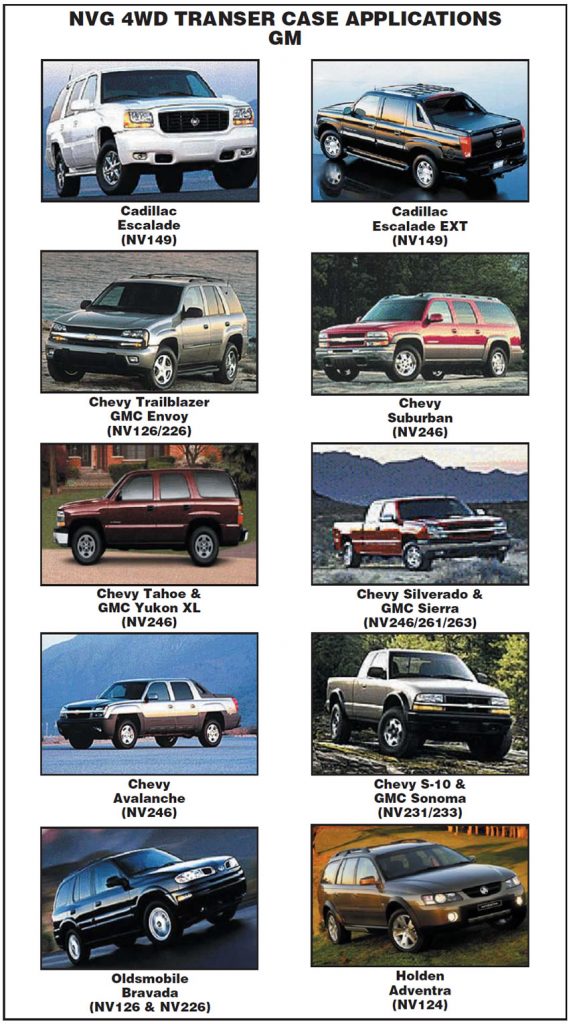

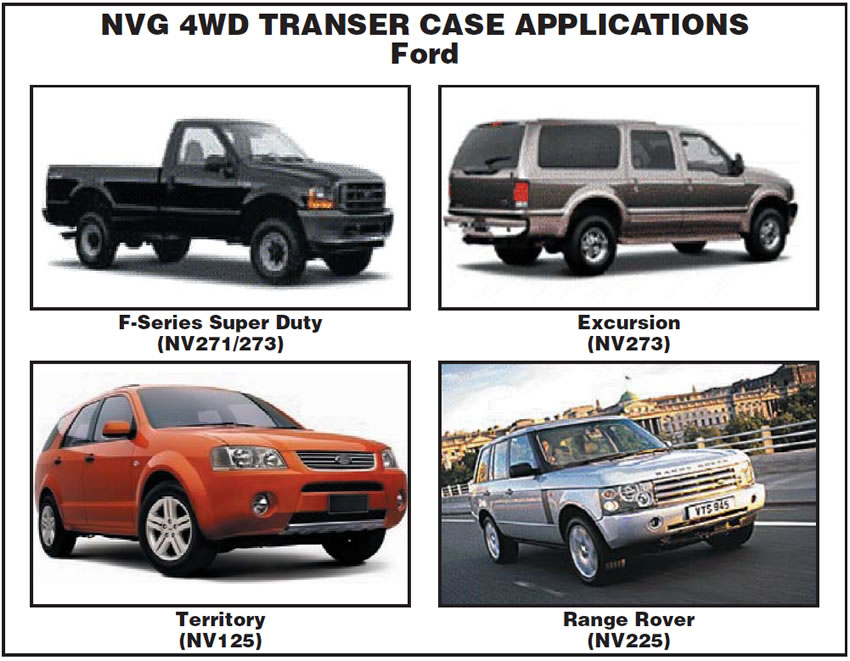

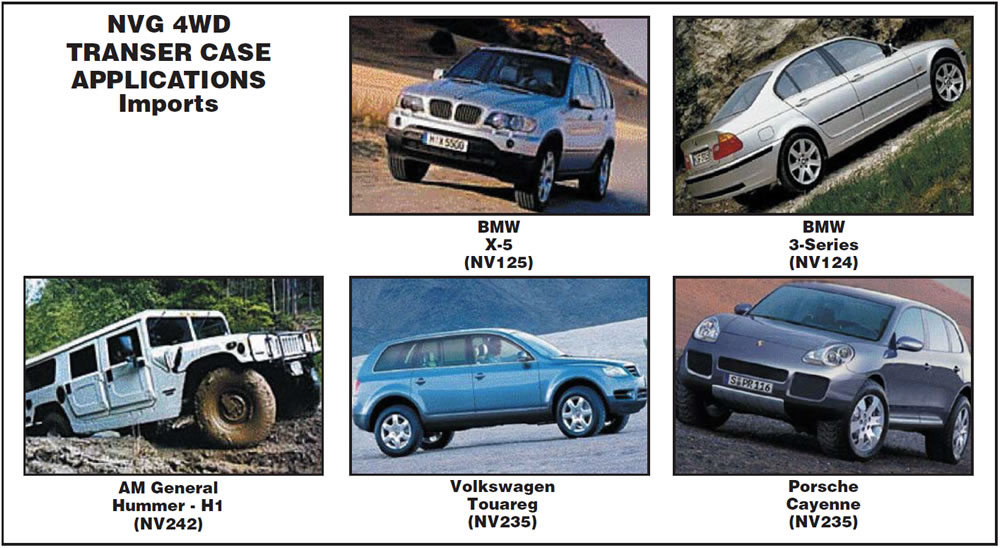

The accompanying model guide will help you to see which units are used in the various makes and models for the 2004 model year.

As with today’s transmissions, the quality and durability of the modern transfer case are excellent. The key to profitability in the repair of these units is to focus on the entire vehicle, which is composed of many integrated systems. There is no trap that you can fall into as bad as the trap you set for yourself. Too many technicians lose focus on the big picture and concentrate only on the unit that is not operating correctly. Their rush to remove and disassemble the transfer case before checking the whole vehicle properly results in thousands of perfectly good units being torn down for no good reason and millions of dollars of wasted labor.

The car is a system of integrated parts. Your doctor always follows the same routine during an examination. He would never schedule you for a heart operation without checking your blood pressure, respiration and blood chemistry and performing an EKG and a battery of other tests. Why are we so quick to blindly dive into a unit when we haven’t checked the simplest things, such as tire pressures and sizes? Follow the diagnostic routines, understand the operation of the vehicle you are working on, and make more money.