Ol’ Skool Customs GmbH, Dieburg, Hessen, Germany

Florian Schuldes makes American trannies Autobahn-worthy

Florian Schuldes, owner of Ol’ Skool Customs in central Germany, works mostly on the drive trains of American vehicles. In this capacity, he’s what we might consider an import guy.

Corvette, Mustangs, Camaros, 4L80, 6L70s, ’80s, 4L60Es, Powerglides, 700s, not to mention ZFs in Fords, Lincolns and Mercurys.

Based in the small town of Zeilhard in the German state of Hessen (also spelled Hesse), about 30 miles south of Frankfurt, he receives transmission projects from all over Europe.

Florian grew up near a U.S. Army post, found friends from American families living there. He also found American cars. His first automotive experience, at the age of 18, was an El Camino with a TH350 transmission.

“It was fun to repair it,” he said. “That was the point when I wanted to learn how a transmission works. I hung around in a shop on the post. I watched a guy disassemble a transmission and reassembled it.”

Florian has been rebuilding transmissions for two decades, and his shop caters to customers driving on the Autobahn. He confirms the Autobahn’s reputation for speed.

“I can go a little bit more than 200 miles per hour,” he said. “We’re all race-car drivers in Germany.”

As a result, the vehicles must be upgraded from daily-driver to racing status. Without modifications, a transmission will be “smoked up” on the Autobahn. This is where Florian does much of his work.

“Most customers come here to get a bigger engine, and they want to have the right transmission for the engine,” he said. “The other half of the customers come here and say, ‘My tranny broke down. Please repair it.’”

New location

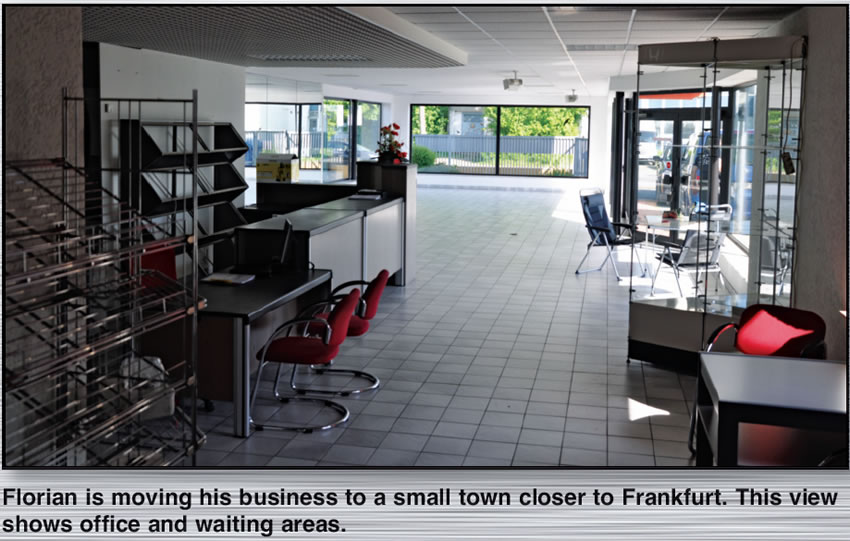

Florian is moving his business to a new facility in Dieburg, another small town a few miles north of Zeilhard. The move was in response from neighbors in Zeilhard who were not comfortable with the transmission shop in their midst. However, the change is for the better as the new location is 2,000 square yards, more than triple the space, and the number of lifts will double to four.

The Dieburg shop will have a big showroom and space to park 35 vehicles, again more than triple the Zeilhard site.

Regulations, standards

Florian described a two-tiered system for drawing up estimates. For individual customers, shop professionals must present accurate estimates in the form of a contract. This approach provides more security for motorists who typically would not have deep knowledge of vehicle systems.

“You have to give them a contract with everything written in, what you will do with the tranny and what it would cost,” he said, noting that warranty and maintenance must also be spelled out. “With the business customers, it’s a little looser.”

Business customers are assumed to be more knowledgeable, he said.

On another note, Florian expressed frustration over the level of expertise among some shops.

“You know the problem of the checkballs smashed into the separator plates. Sometimes they look like a crater; they’re hanging between the separator plates. Every single 4L60E or 65E or 700 tranny I get from other shops never use a new plate – never. And they never use new bearings, new bushings, nothing at all.”

In contrast, specialized shops typically strive to attain high standards. Their technicians are those who have “grown up with the trannies,” and Florian counts himself among them.

Research and development

“We want to figure out why trannies break down,” Florian said.

Cooling: With Autobahn speeds, the danger of overheating escalates. He has focused most seriously on better coolants and better cooling systems. He offered some examples.

“The 4L60E and the 700s have a weak 3-4 clutch — in Germany as well as in the Untied States. Mostly, they smoke up and they are gone, but in Germany you have higher speeds, more temperature in the trannies.”

Exploration: For newer transmissions, on which nobody has experience, the path to knowledge starts with disassembling a unit and inspecting what you find.

“I talked about the 6R60 or 6R80 trannies on the Mustangs here in Germany, the six-speeds. They’ve got problems with vibrations, and we figured out the clearance of the tail bearing is not enough, or it’s too close or too wide. We figured it out with measurements of vibration sensors.” The cars are built to American specs, but they aren’t stressed like they are on the Autobahn.

Racing secrets: While speed proliferates on the Autobahn, competitive racing happens on just a few tracks in Germany, Florian said. However, he has a number of racing customers who seek his rebuilding skills. These customers expect strict confidentiality from Florian:

“They say, don’t talk about my tranny. Don’t talk about my problems with the tranny. And tell nobody I was here. No photos allowed! We have milky glass so nobody can look inside.”

Looking ahead

Florian is always looking for young, smart technicians to hire and train. He described something like the tech shortage that American shops face. In Germany, few youngsters grow up learning about how cars as they watch their fathers perform maintenance and repairs at home, he said. While American kids learn about cars from their fathers, not enough kids choose to make it a profession.

“Most of the people who work here in Germany on transmissions, they are familiar with manual transmissions, except in the last few years when automatics are getting attention. In Germany, you drive normally stick shifts. Nobody drives a fast car or a sports car with an automatic transmission.”

Training for automotive technicians is lacking, he said.

“When you learn the job auto mechanic, you maybe see a cut-in-half transmission. You know what a clutch is, a valve body, but you never work on it. We the transmission rebuilders are pretty rare, specialized people. The problem is getting new young people who are interested in learning how to rebuild, how to improve a transmission. And my goal with the new shop is to bring my experience of the last 20 years to young people and explain how to rebuild automatic transmissions.

“The main problem when you grow up with transmission repair, like I did, was to do it step by step, to do many mistakes, but you later understand how the transmission works.”