Torque Converter Tech Tips

- Subjects: Minimum thicknesses for cover and lockup piston; matching piston and cover

- Unit: Chrysler 518

- Essential Reading: Rebuilder, Diagnostician

- Author: Dave Roe

The toughest part of rebuilding any torque converter is not building a heavy-duty converter but building the best converter possible for a price that is both competitive and profitable.

The late-model 518 is a prime example of this statement. When we get OE cores, the covers measure 0.160 to 0.165 inch thick if they are undamaged. The front covers can normally be cleaned up by machining off 0.005 inch of material. The challenge comes when we get a cover that was galled or damaged by a major lockup failure. In these instances, you may have to machine off as much as 0.015 inch, and at this point you end up with a cover that is only 0.145 inch to 0.150 inch thick. The question is, how far can you go? Where is the line between thick enough and no longer thick enough?

TCRA recommends 0.140 inch as a minimum thickness for the lockup surface. I have talked with other builders about this and they draw the line at 0.140 inch, but I draw the line at 0.150 inch thick. Below that, we part out another core in search of a cover. We all know that the cover can balloon slightly in some conditions. This problem becomes worse if the cover thickness has been reduced by machining. For sheer strength and resistance to ballooning, the billet cover is the best way to go, but the cost of a billet cover raises the overall cost of the converter considerably. Cores are cheaper than billet covers, especially when you add a new ring gear.

Another area where we must walk the line is the converter lockup piston. In Figure 1, the cross-sectioned piston and cover have an interference problem. The thin cover and over-machined piston do not like to live together. To help identify the problem, you can use some simple tools and tests.

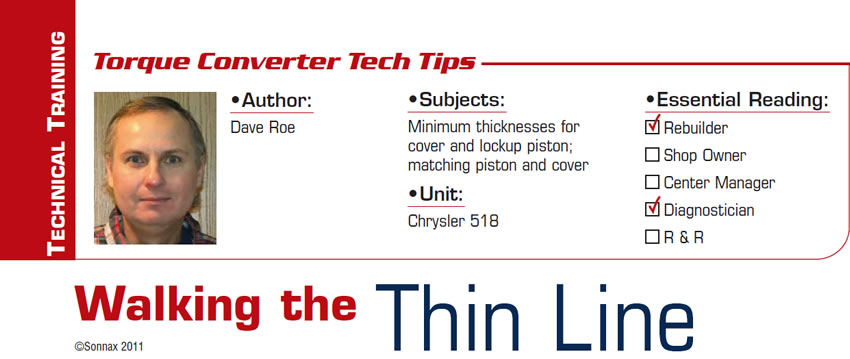

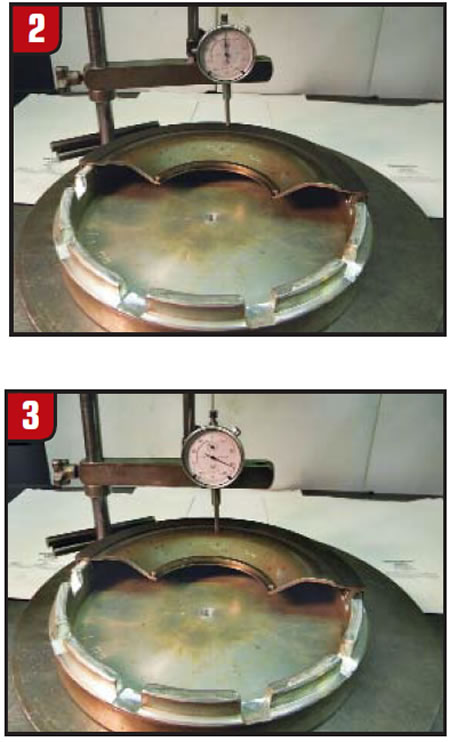

First, not all pistons are the same. The piston in earlier models can have a higher profile – I call these “high humps.” We measure the difference from clutch surface to the highest point on the flywheel side of the piston (figures 2 and 3). A normal, post-bonded piston with a 0.070-inch lining has a height of 0.105 inch to 0.115 inch. This is a normal measurement for 1996-up models.

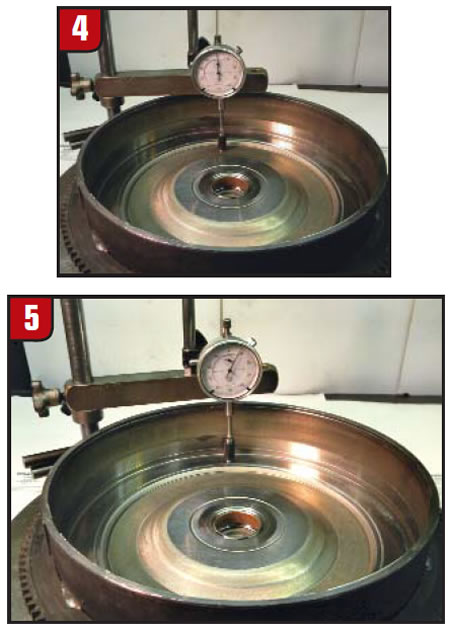

Pistons that measure 0.125 or higher are the high-hump variety commonly found in early converters. These pistons can be used only in early units or late ones with deep wells in the cover (figures 4 and 5). You can use a cross-sectioned piston (Figure 1) to help find the shallow-well covers or do a measurement.

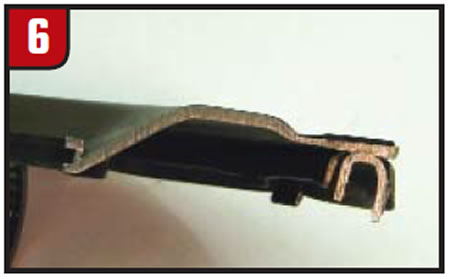

In Figure 6, notice how the piston surface tapers thinner from the outside to the inside. The thinnest point, where the piston transitions from surface to hump, is where ballooning will occur. This problem is made worse when the piston surfaces are over-machined or cut too far into the hump.

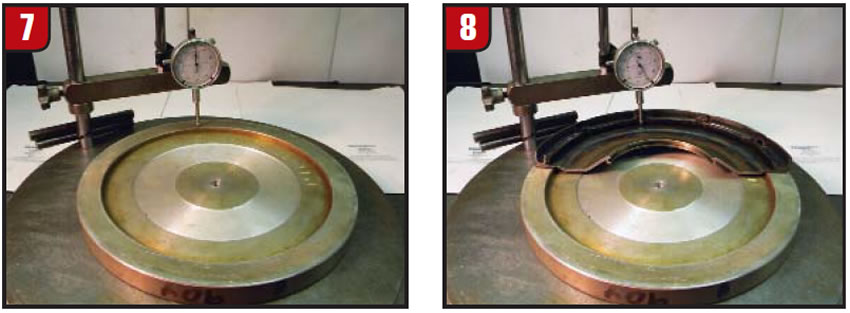

Piston surface thickness can be measured with a bonding die, height gauge and dial indicator (figures 7 and 8).

You must measure the piston in two or three places, because the thickness can vary. Use an average of your findings or the lowest measurement. The thickness of an un-machined piston, measured at the thinnest point on the inside of the spring retainer, should range from 0.098 inch to 0.115 inch. TCRA recommends a minimum thickness of 0.060 inch after machining for either regular or high-hump-style pistons. I draw the line at 0.075 inch.

Remember that with this unit, we all walk the thin line.

Dave Roe is the manager of the torque-converter-rebuilding department at Fort Dodge Transmission, a transmission-rebuilding company and full-service repair shop with 35 employees in Fort Dodge, Iowa. Roe has been with the shop since 1987, taking pride along with his co-workers in keeping in step with change and producing a quality product.

©Sonnax2011