Technically Speaking

- Author: Wayne Colonna

- Subject Matter: 41TES

- Issue: Line pressure- P0896

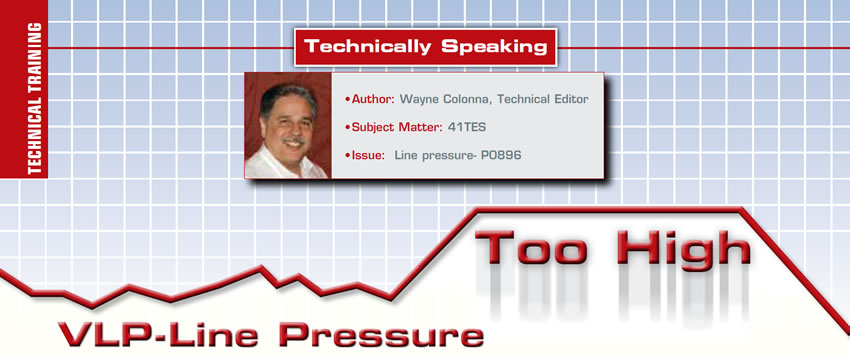

A 2014 Dodge Journey 2.4L with a 41TES transmission came in to Electronica & Transmisiones in Buenos Aires Argentina. It had code P0869 set for Line Pressure High. Leonardo Luercho went out with the vehicle using his scan tool to begin his diagnostic approach. While observing the data parameter IDs in his scan tool, he noticed that there was a difference between desired and actual line pressure. Figure 1 is a photo of the graph displayed in his scan tool. The blue, more-active line is actual line pressure provided by the VLP sensor. The black, less-active line is the desired command given to the VLP solenoid by the computer.

His first response was to change the VLP solenoid and pressure sensor. In the process he verified that he had a good 5 volts supply and a good ground. He also verified that the VLP command wire and signal wire for the sensor were not compromised going to the PCM. Once done, he did a VLP data reset and a quick learn. Soon into the road test, he saw the same difference between desired and actual line pressure in his scan tool. And P0896 set again.

Information from Chrysler provides a very clear explanation on how the system works. It begins by providing duty cycle information in relationship to desired and actual line pressure. It then goes on to say:

“The Transmission Control System calculates torque input to the transmission and uses it as the primary input to the desired line pressure calculation. This is called Torque Based Line Pressure. In addition, the line pressure is set to a preset level during shifts and in Park and Neutral to ensure consistent shift quality. The desired line pressure is continuously being compared to the actual line pressure. If the actual line pressure is consistently higher than the highest desired line pressure ever used in the current gear, the line pressure high DTC P0869 will set.”

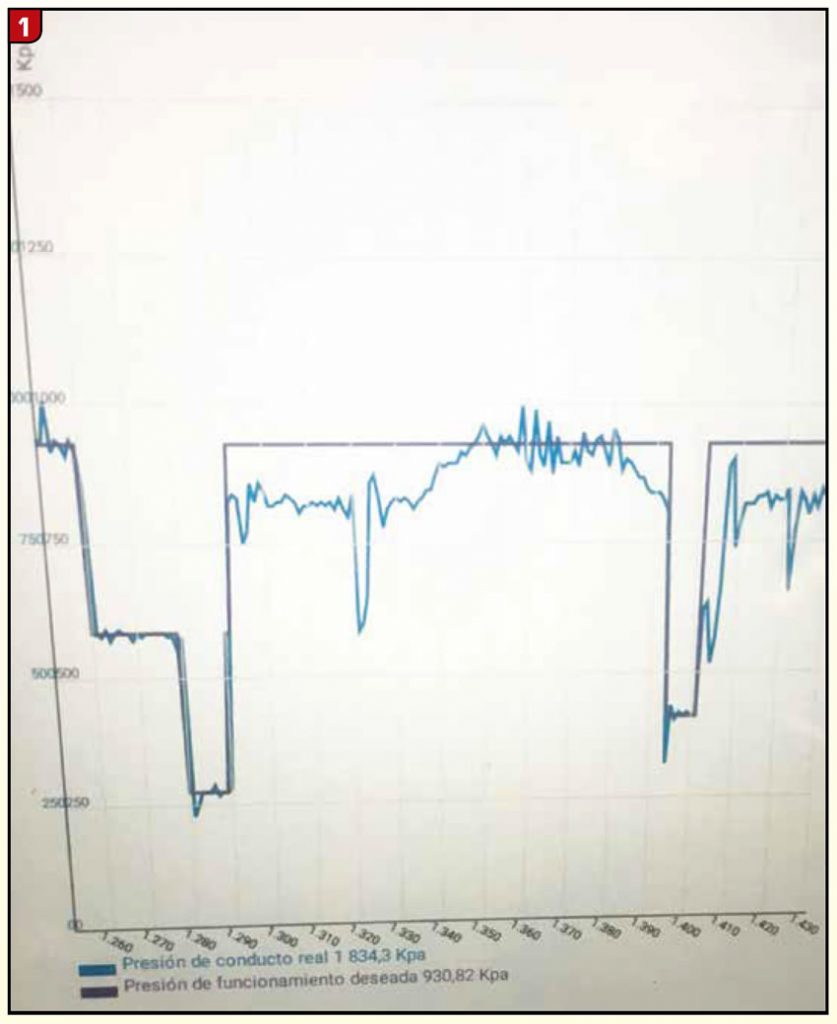

Torque Based Line Pressure control is critical for the VLP system to function correctly. This prompted Leonardo to clean the throttle body and perform an ETC relearn function with his scan tool. Once that was completed he took it on a road test and the transmission functioned flawlessly. His desired and actual were in sync (Figure 2), which in turn resolved the issue of having P0869 from setting.

As a result, he now has the following routine when working with VLP systems.

- Transmission quick learn

- VLP data error and counter set on zero

- Clean and reset the throttle body

This is quite helpful since Chrysler doesn’t offer this as a possibility. They do produce a list of what may cause P0896 to set but the throttle body isn’t one of them. After talking about bad connections, open or shorted wiring, sensor or solenoid failure, or sticking pressure regulator valve, their last possibility is a bad PCM.

If this list was followed, a PCM would have been purchased unnecessarily and would have caused another type of high line pressure!