Shift Pointers

- Subject: Valve-body problems and solutions

- Unit: Honda BAXA, MAXA, B7XA; Ford 5R55W, 5R55N, 4R55E/5R55E, 5R110W

- Essential Reading: Rebuilder, Diagnostician, R & R

- Author: Pete Luban, ATSG Technical Supervisor

In all the years of building transmissions, I think the worst thing that could happen is having the R&R guy, manager or owner come back after a road test and tell you, “It’s not working.” All of a sudden you get this knot-in-your-stomach feeling that makes you wish this were not really happening.

So you take the vehicle for a ride to see what it’s doing; maybe it needs a minor adjustment or more fluid, or it’s an engine problem – anything but MY transmission.

Once you admit to yourself that it doesn’t work right, you come to the determination that it’s a valve-body problem – not so bad; at least the unit doesn’t have to come out, which makes the R&R guys happy even though they’re not thrilled about handling a hot valve body.

Of course, depending on what it takes to get the valve body out, it could be another story. In some instances, I’m sure the R&R guys would rather pull the unit out.

All this brings us to some valve-body problems that have been coming across the ATSG tech line lately. Some problems are man made, but others just happen.

The first problem is found on Honda Accords with the BAXA/MAXA transaxle hooked to the four-cylinder engine or with the B7XA behind the V-6 engine.

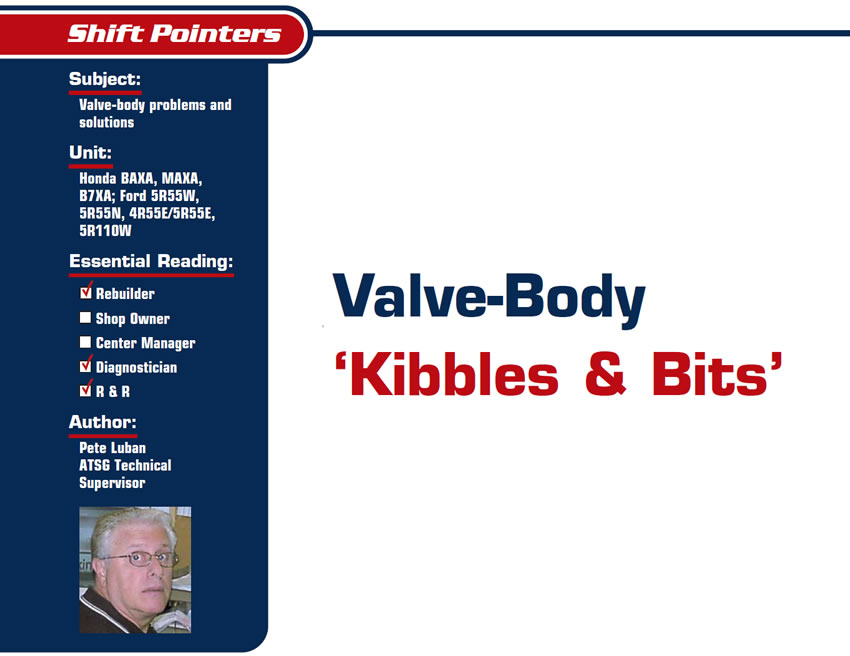

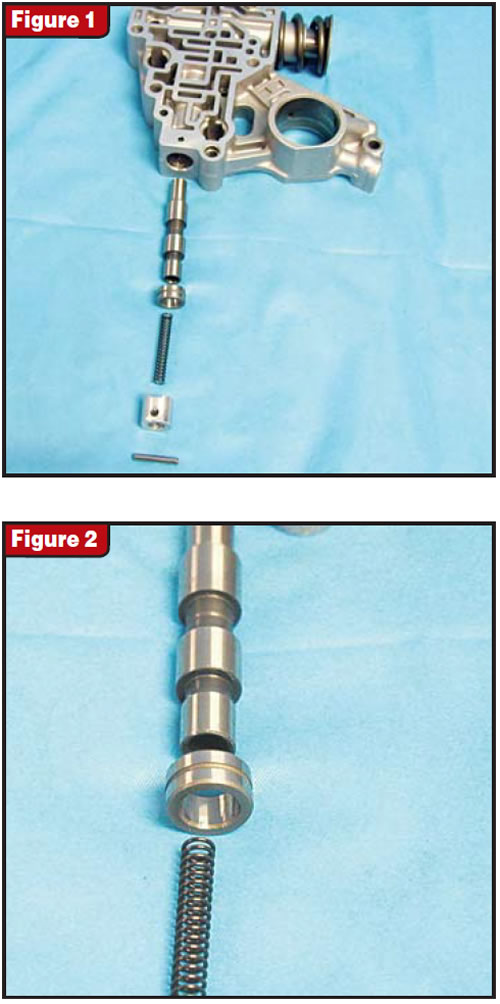

TCC slip or cycling with the possibility of storing code P0740 in a BAXA/MAXA/B7XA may be caused by leaving out the lockup-control-valve sleeve. Figures 1 and 2 show the sleeve and valve lineup.

The steel sleeve can roll away while the valve body is on the bench, disassembled, for cleaning purposes. Since the lockup-control valve is one of the valves responsible for controlling the rate of lockup-release oil, leaving this sleeve out can reduce converter-clutch backpressure, resulting in the complaints mentioned.

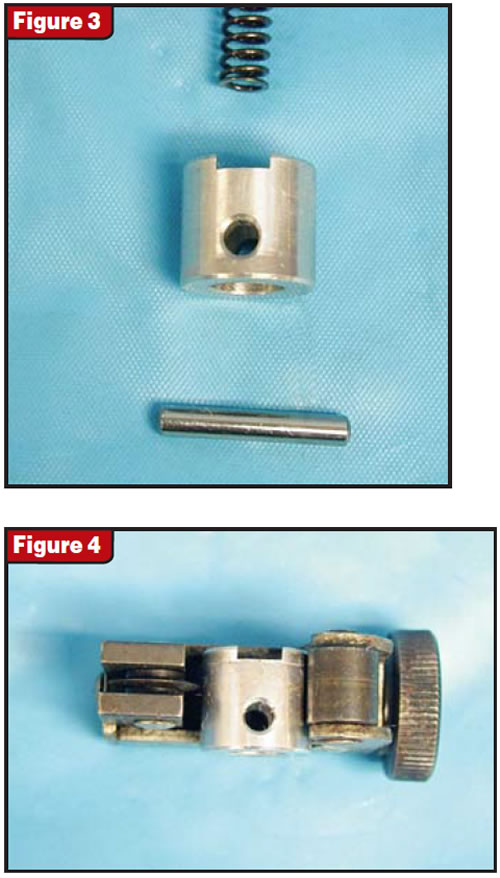

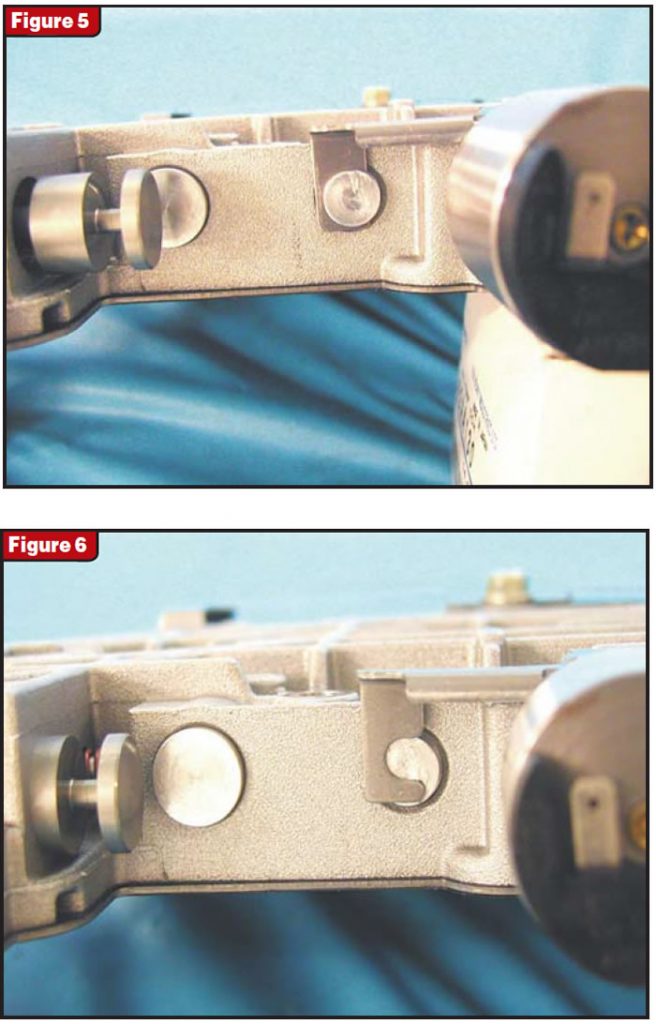

While we’re on the subject of code P0740 – this is one of the most-common calls we get – one of the more-common causes is leakage of the lockup-control-valve bore plug (see Figure 3).

The best way to fix a leaking bore plug is to machine a groove in the plug and install an O-ring in that groove. If this method is not available, you can always use your tubing cutter to cut a ridge in the bore plug, as shown in Figure 4, so the plug fits tighter in the bore. However, this may not last as long as the O-ring fix would.

Be aware that the BAXA/MAXA also has a sleeve on the 3-4 orifice control valve, in the secondary valve-body section. Leaving this sleeve out can cause a poor or flared 3-4 shift.

The B7XA has one of these sleeves on the reverse CPC valve, in the main valve-body section. Leaving this sleeve out would certainly cause slipping or a shudder in reverse.

Our next valve-body kibble concerns the Ford 4/5R55E family of transmissions. The bore plug for the 2-3 shift valve is held in place by the solenoid retaining bracket that holds the EPC, SS2 and coast clutch solenoids by means of a hook at the end of the bracket that hooks around a knob on the bore plug as shown in Figure 5.

What sometimes happens is, while struggling with the positioning of the bracket, you may not pay attention to the hook position. It then ends up on top of the bore plug instead of around the knob, pushing the 2-3 shift valve in too far (see Figure 6).

When the valve body is installed this way, the 2-3 shift valve will block oil to the reverse servo by positioning the spool of the valve in the way of the oil, which normally travels between the spools on its way to the servo, resulting in a no-reverse condition.

Our next valve-body bit comes under the heading of #@&* happens. In this particular example, the transmission is the 5R55W. The fluid was severely burnt, lockup did not work and a P0741 code was stored. Once the unit was rebuilt and installed with a reman converter, code P0741 returned during the road test.

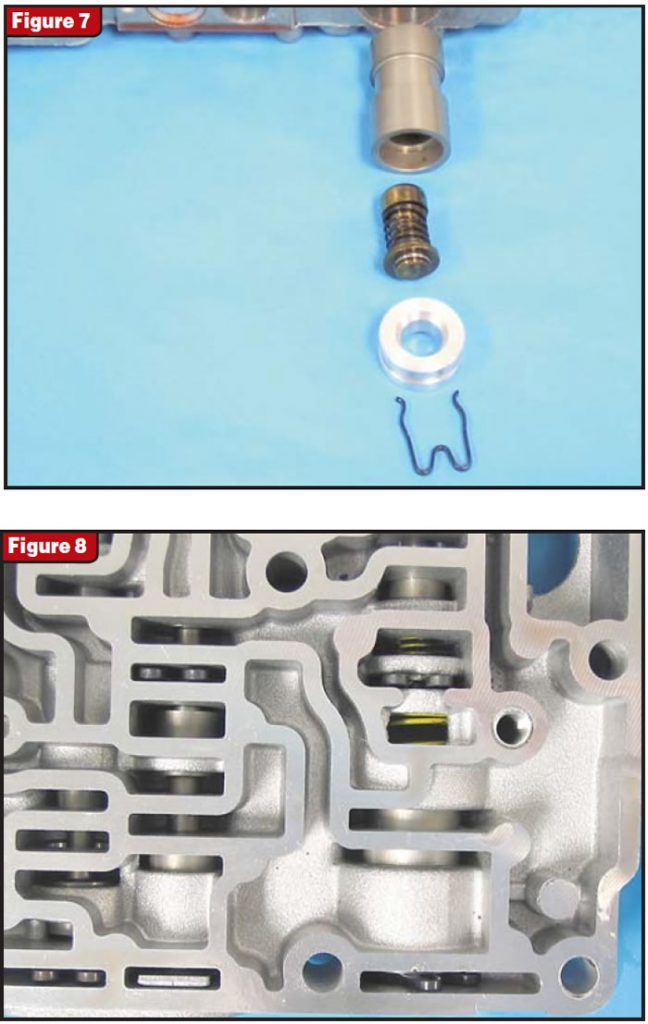

To make a long story short, because code P0741 is never a short story, the cause of the problem was the thermo-bypass valve, shown in Figure 7. The valve is supposed to open when the ATF warms and allow oil flow through the cooler. When the fluid is cold the thermo valve bypasses the cooler and directs flow to the lube circuit. This is necessary for two reasons: One is to allow oil flow to lube the gear train in the event the fluid in the cooler has jelled. Those who live in places that get colder than a brass monkey know what I mean. The other reason is that should the cooler become blocked, fluid will still circulate through the transmission, thereby saving the hard parts.

In a 5R55W the thermo valve is in a sleeve. It flops around in this sleeve, which is normal; it doesn’t fit snugly as other valves do. It also affects lockup operation because it is in the same bore as the lockup-control valve (see Figure 8).

Other Ford transmissions, such as the 5R55N, 4R/5R55E and 5R110W (it’s in the pump), also have this valve. A cooler-flow check should reveal a problem if the thermo valve does not open.