Technically Speaking

- Author: Wayne Colonna

- Subject Matter: 6L80/90

- Issue: “UNIGEAR”

Technical Training

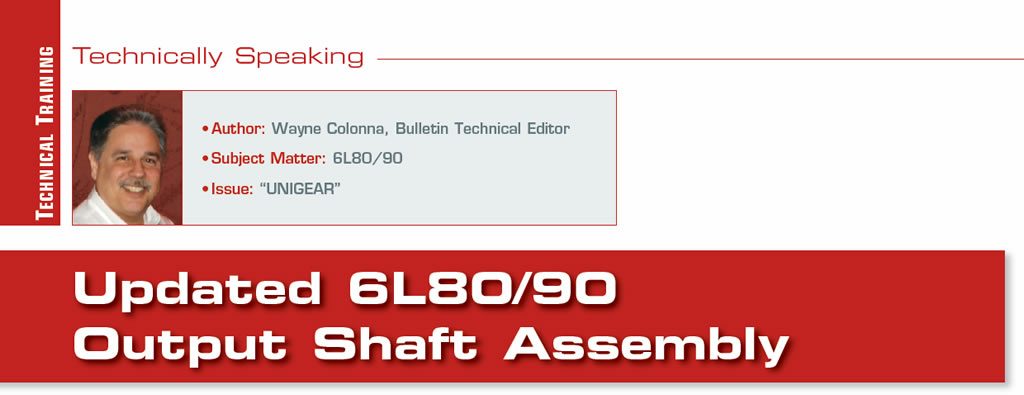

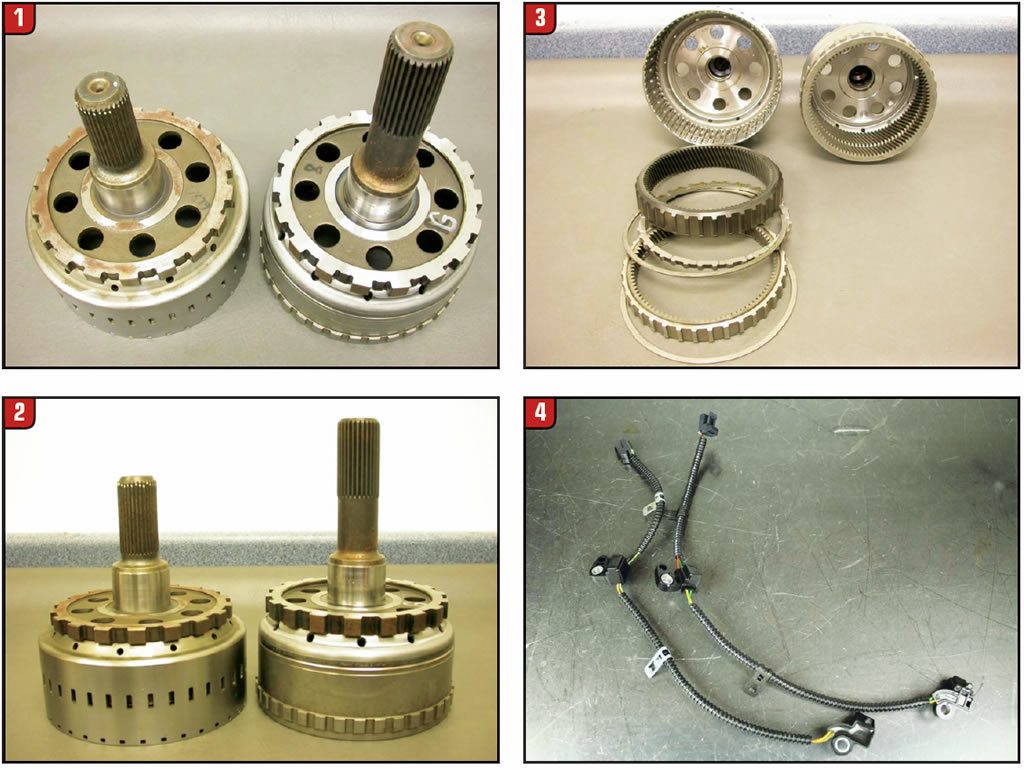

During model year 2012, Chevrolet and GMC trucks equipped with the 6L80/90 transmission received an updated output-shaft assembly. The previous output-shaft assembly was comprised of a separate output shaft, output carrier ring gear, ring-gear spacer, output carrier internal front gear and snap rings as seen on the left in figures 1 through 3. This required the use of a specific style output transmission speed sensor also shown on the left in figures 4 and 5.

The updated output shaft assembly known as the “UNIGEAR” is now all one piece. All components of the previous design are now an integral part of the output shaft (right side in figures 1 through 3). This output shaft assembly required the use of a different style speed sensor located in the harness itself (right side in figures 4 and 5).

The updated design was done as a cost-reduction measure. Although there have been reports in the field of a “snapping” sound during a garage shift from reverse to drive. Installing the UNIGEAR output shaft assembly seemed to have eliminated this garage shift noise.

Looking at the previous and updated speed sensors in figures 4 and 5, there is an obvious difference in design. The updated output speed sensor has a different step designed into it to accommodate the new UNIGEAR output-shaft assembly. This redesigned step makes the sensor slightly shorter so as to provide the proper air gap.

The UNIGEAR output-shaft assembly will back service all 6L80/90 transmissions as long as the “stepped” output speed-sensor assembly is used.

Using the previously designed output speed-sensor assembly with the UNIGEAR output shaft assembly will result in immediate damage to the output speed sensor.

Using the new “stepped” output shaft assembly with the previous output shaft will cause too much of an air gap, which will result in a DTC being set.

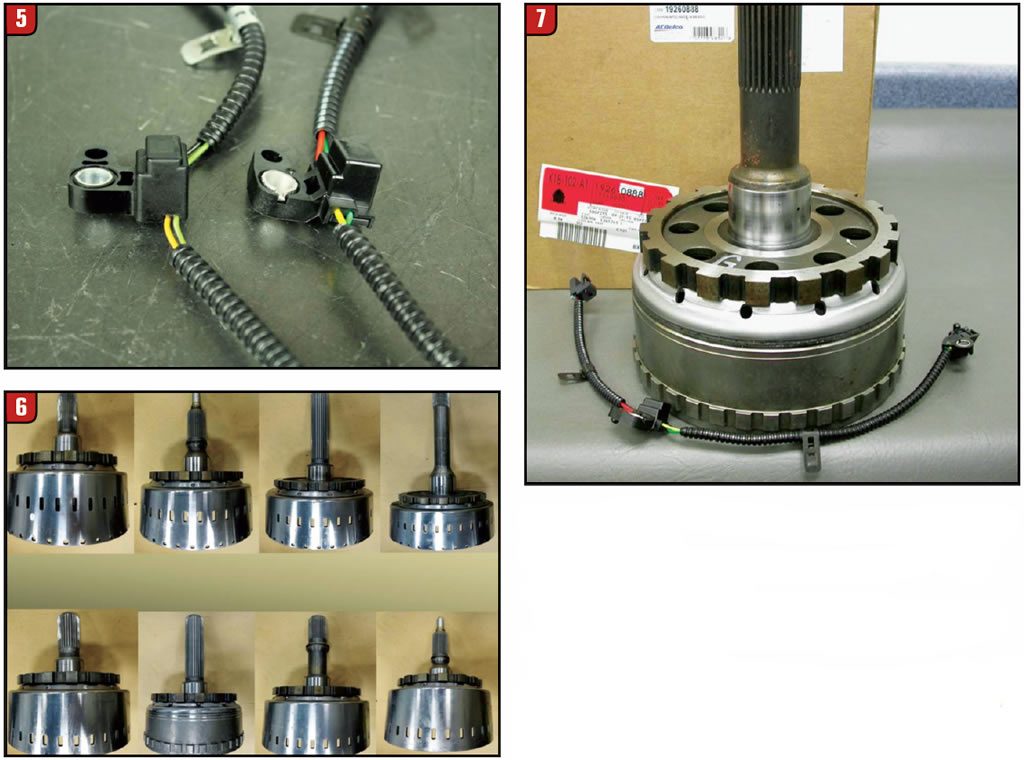

The UNIGEAR output shaft assembly kit is model dependant which will require the VIN number to acquire the correct shaft (Figure 6).

The UNIGEAR output shaft assembly kit contains the updated “stepped” designed speed sensor assembly (Figure 7).

- Previous design transmission speed sensor assembly: 24265535

- Updated “stepped” design transmission speed sensor assembly: 24265536