Up to Standards

- Subject: Electronics and diagnosis

- Unit: NVG 146

- Vehicle Application: Grand Cherokee SRT8

- Essential Reading: Rebuilder, Diagnostician

- Author: Mike Weinberg, Rockland Standard Gear Contributing Editor

In last month’s article we looked over the mechanical functions of the Magna Powertrain 146 transfer case found in the Jeep Grand Cherokee SRT8 model. To review briefly, this model is Jeep’s muscle car and is capable of 0-60 times under five seconds with its 6.1-liter Hemi engine, five-speed automatic transmission and single-speed 146 transfer case.

The torque rating for this engine is 420 lb.-ft. at 4,800 rpm. The W5A580-5 automatic transmission has adaptive electronic controls and is equipped with driver-interactive manually controlled AutoStick and electronically modulated torque-converter clutch. Transmission ratios are pretty stout: 3.59-1 1st, 2.19 2nd, 1.41 3rd, 1-1 4th and 0.83 5th (overdrive). The differential ratios are 3.73-1, and this combination will put you way back in the seat if you jump on the throttle. The 146 transfer case is a single-speed, full-time unit that uses a solid electronically operated clutch pack as a center differential, with the front and rear differentials being of open design. There is no shift lever or driver controls for the transfer case, which provides on-demand torque at all times.

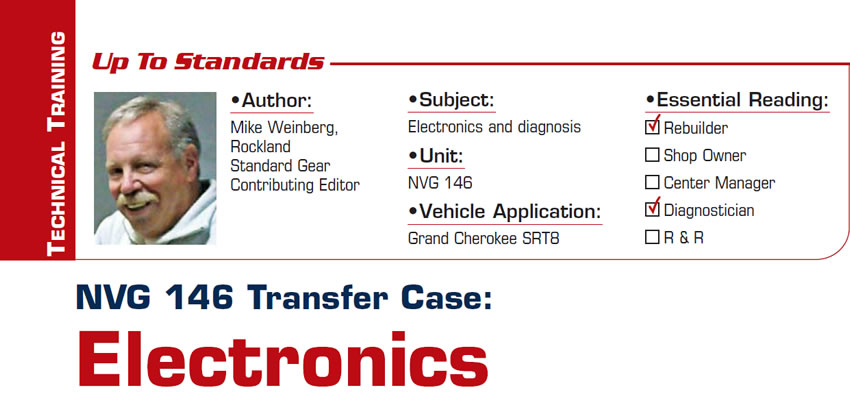

The controls for the 146 transfer case’s active clutch are in the Final Drive Control Module (FDCM), and communication is from the CAN C bus. Wheel speeds are monitored, and any differences between axle speeds will have the computer engage the clutch pack to send up to 50% of the torque to the wheels that need it. The computer is capable of setting 32 diagnostic codes, 27 of which will be C codes and the other five U codes.

We have included a trouble-code chart (Figure 1) for reference and a transfer-case wiring diagram (Figure 2). You will find the FDCM below the left-rear seat. For any complete diagnosis you will need the diagnostic trees, which we do not have space to show here but are easily obtainable from Mitchell OnDemand and other sources. One quick warning: If during service, diagnosis or repair you disconnect the front-differential solenoid, the rear-differential solenoid or the transfer-case-motor connectors, all DTCs must be cleared in the computer or the FDCM will detect this as a problem and turn off the switched battery solenoid-supply circuit.

Understanding the systems involved that affect the transfer case and drivability issues is the key to being successful in any diagnosis or repair of this system. You have a vehicle with a great amount of power and torque, and a population of owners who are not drivers but merely people who know how to make a car go. Human nature being what it is, most of these drivers will be over their heads with this vehicle. So the manufacturer has added other programs to keep the customer from getting in trouble, so that they will be around to buy another vehicle someday. The system is called ESP (electronic stability program) and has subprograms within it, which are the antilock-braking system, traction-control system (TCS), brake-assist system (BAS) and electric roll-mitigation system (ERM).

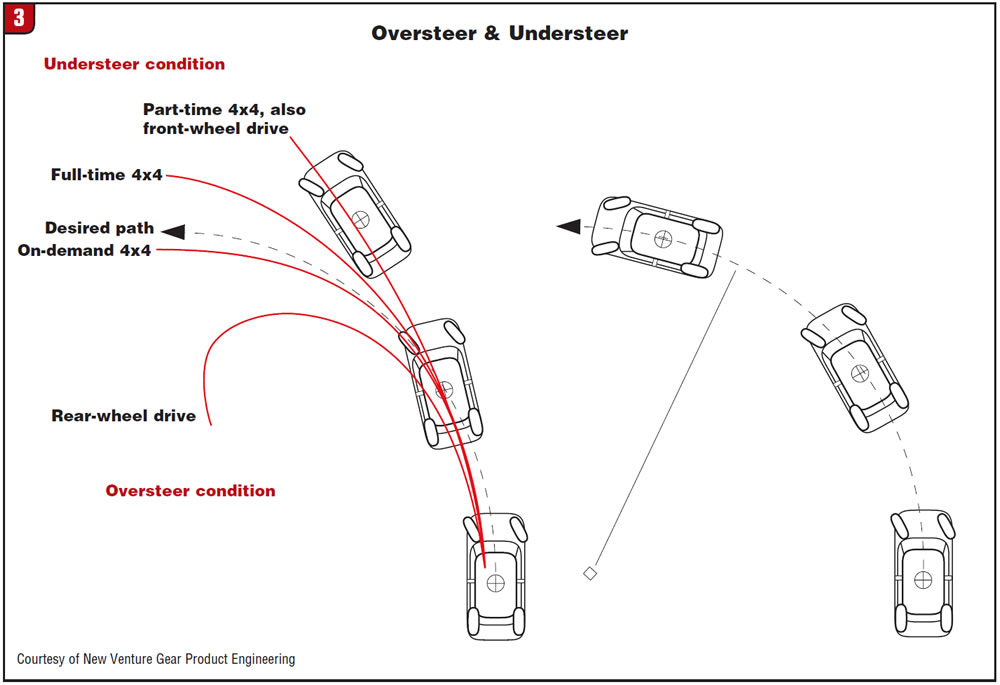

By design, all these programs work together to keep the customer on the intended path through a corner. The diagram in Figure 3 relates to speed- and traction-induced problems during turns that result in understeer or oversteer conditions. Understeer, or push, is created by carrying too much speed into a corner so that the vehicle drives through the traction of the front tires and will not be able to turn in. Oversteer, or loose, is created by carrying too much speed in exiting the corner, so that the rear wheels lose traction and want to pass the front wheels. In the immortal words of Richard Petty, when you understeer you see the crash happen; when you are loose, you don’t.

The TCS monitors wheel spin on each of the driven wheels, and if it detects wheel spin it activates the transfer-case clutch pack and automatically applies brake pressure to the spinning wheel, and engine power will drop. The TCS can act like a limited-slip differential to control slip across a driven axle. If one wheel is slipping and the brake for that wheel applies, the power transfers to the wheel on the opposite side.

The BAS measures the force and speed of the driver’s application of the brake pedal and optimizes brake pressure in emergency situations, while the ABS prevents individual wheels from locking up and creating a skid situation. With this system it is important to keep a steady brake force on the pedal, as pumping the brakes will cause the ABS to lose effectiveness.

The ERM prevents wheel lift due to body roll in higher-speed turns. It monitors the steering angle and the vehicle road speed. The computer compares the actual speed and turn rate against an internal dynamic program, and when the rate of turn and speed will cause a certain amount of wheel lift due to body roll and suspension travel, it applies individual wheel braking, reduces engine power and engages the transfer case to add traction to the wheels that need it.

The ESP uses all the functions mentioned to control understeer or oversteer and keep the vehicle on its intended path using brakes, transfer case and reduced engine power to keep the driver on the road and off the guard rail.

The main point to take away from this discussion is that all diagnostics need to start with a complete examination of the systems related to the transfer case. If you are quick to pull a unit without reviewing how these systems work together, you will lose every time. Diagnosis starts with a check on battery voltage, a check on tire pressures and sizes (all tires must be within 1/4 inch in circumference), reading the diagnostic codes and then making sure that all the related systems are functioning correctly. A stuck caliper, worn brakes or an ABS problem can send you into an incredible waste of time.

This transfer case is relatively simple, just a one-speed unit with a clutch pack that is not under the driver’s control. Sometimes a quick fluid check in the transfer case will determine whether you have an internal problem, but always work from the outside in and condemn the unit only when you are sure that all other related systems are functioning properly.