Body of Evidence

- Subject: Different design levels of valve body

- Unit: AW 55-50

- Vehicle Applications: GM, Nissan, Saab, Saturn, Volvo

- Essential Reading: Rebuilder, Diagnostician, R & R

- Author: Jeff Parlee

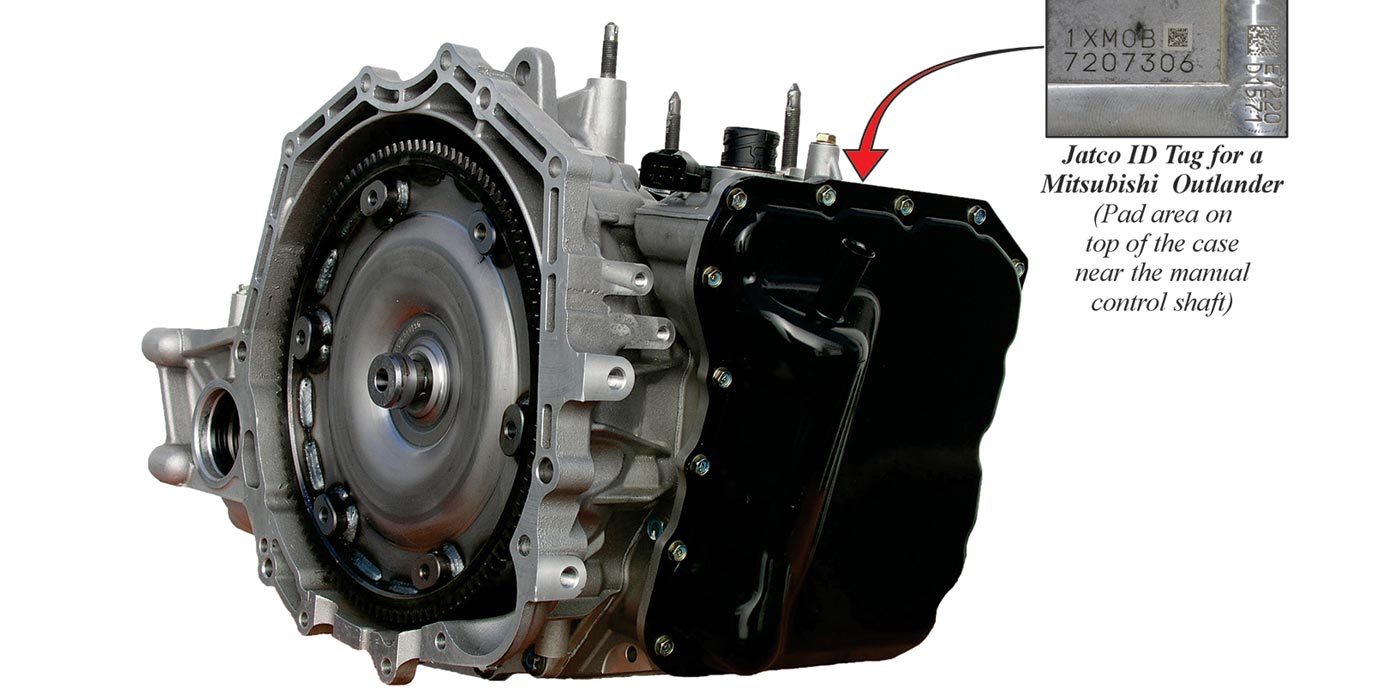

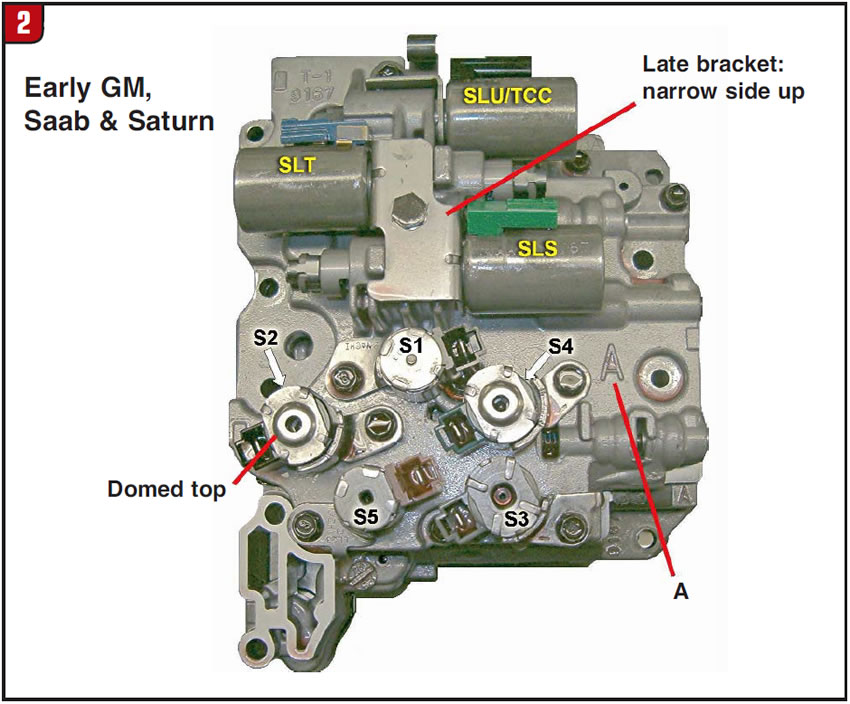

Let’s start with identifying the AW 55-50 valve body and the differences that matter when you’re choosing a replacement valve body. There are four castings, which can be identified by either a letter cast into the valve body just to the right of the S4 solenoid or a blank spot.

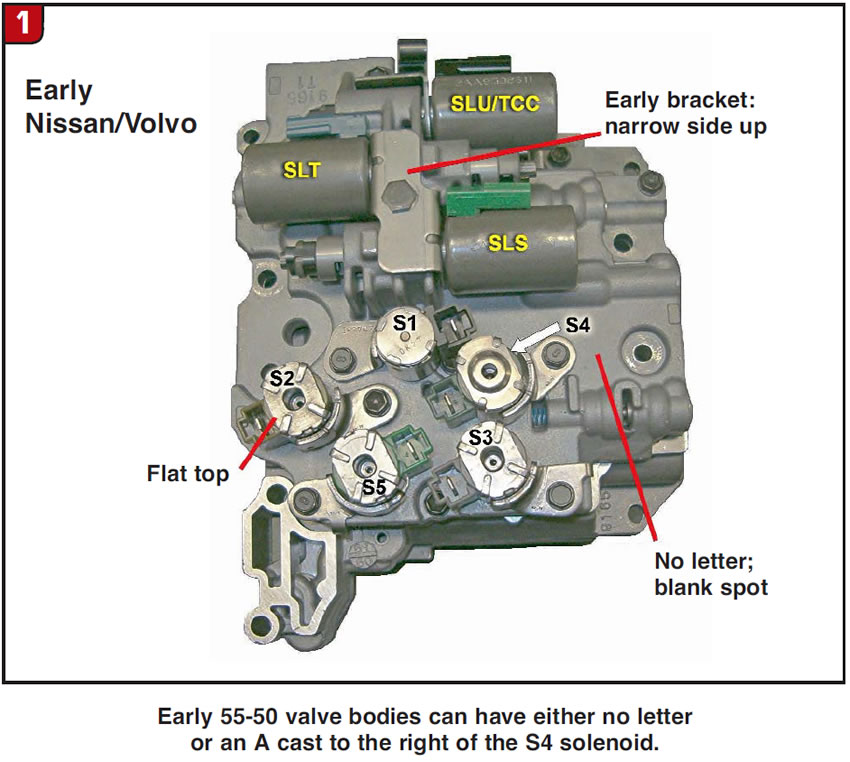

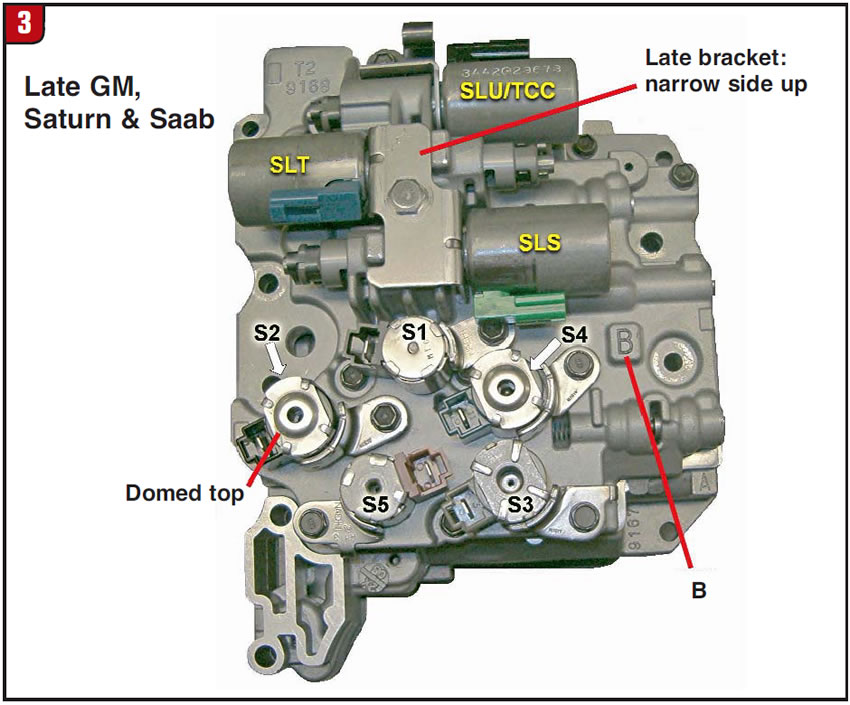

The blank-spot (no letter) and A castings are considered early because the electrical connectors on the SLS and SLT solenoids face up (figures 1 & 2).

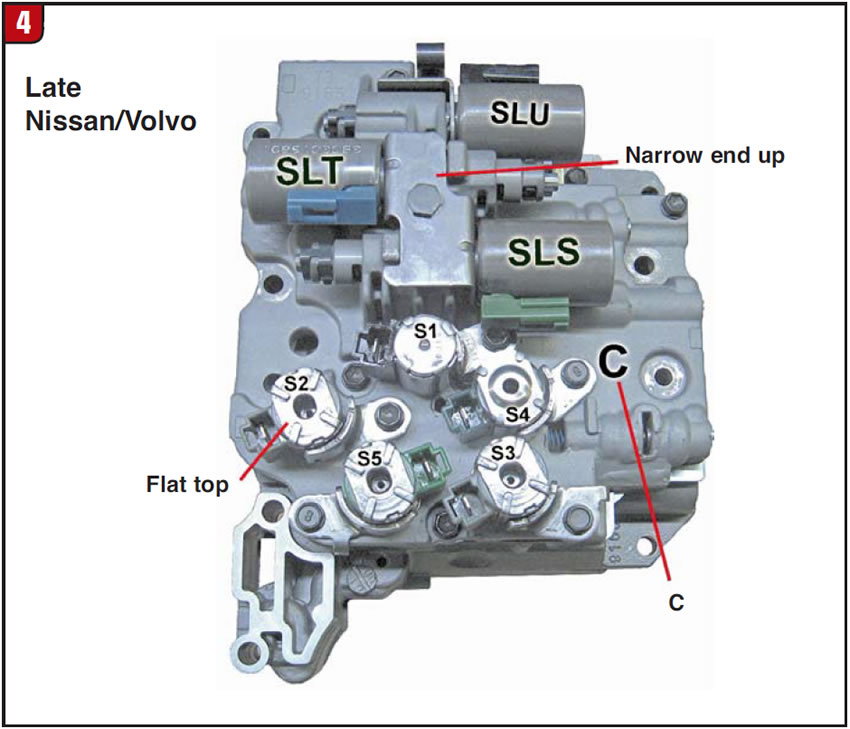

The B- and C-casting valve bodies are considered late because the SLS and SLT solenoids have the electrical connectors facing down (figures 3 & 4). The early vehicles (2000 to sometime in 2002-2003) had an internal wiring harness that was just long enough to connect to the SLS and SLT solenoids with the electrical connectors facing up.

When the B valve body was introduced with the SLS and SLT electrical connectors facing down, the internal harness was made longer to accommodate the change.

The next wrinkle in our identification is which S2 solenoid the valve body has. Nissan and Volvo use a normally closed S2 solenoid that has a flat top with four ribs radiating from the center hole on top to the outside corners (figures 1 and 4). GM, Saab and Saturn use a normally open S2 solenoid that has a domed top (figures 2 and 3).

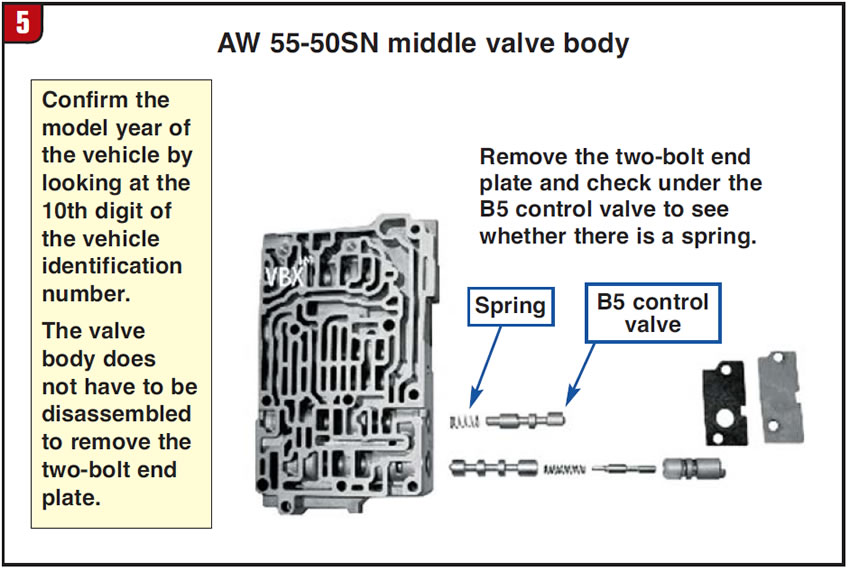

Now we can look at an AW55-50 valve body and tell whether it is early or late and whether it is a GM style or a Nissan/Volvo style. That was all you needed to know until 2005. Beginning in the 2005 model year, Nissan, GM and some Volvos changed the way that they fire the solenoids and added a spring to the inboard side of the B5 control valve. If a valve body without the B5 spring is installed on a 2005 or newer vehicle, you will get a nasty 3-2 coast-down clunk. If you install a valve body with a B5 spring into a 2004 or older vehicle you will get a 2-3 flare that will not adapt out.

It is important that you verify the model year of the vehicle by looking at the 10th digit of the vehicle identification number (VIN). A 4 in the 10th position would mean 2004, a 5 would mean 2005 and so on. If the vehicle is a 2005 or later, most will have the B5 control-valve spring (Figure 5). An exception to the rule is that some early Saturns have a B5 control-valve spring. It is best to order a replacement valve body by identifying the letter code and whether it has a B5 control-valve spring because of various updates by the manufacturers over the years.

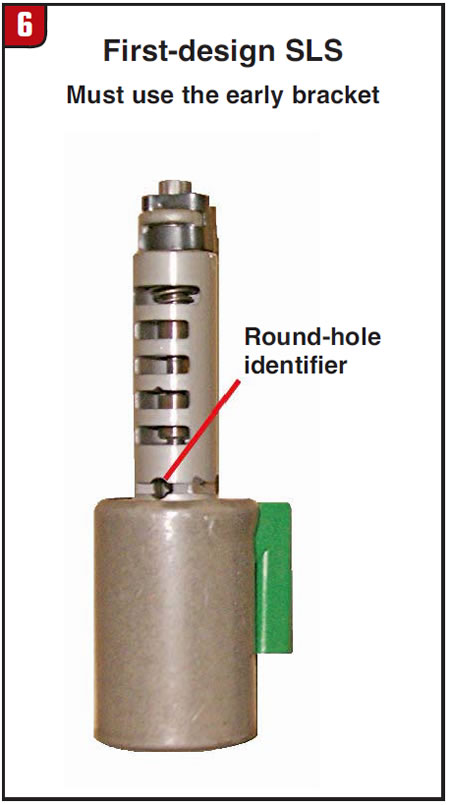

Let’s talk about the linear solenoids and the correct way to install the SLT/SLS-solenoid bracket. There are three design levels of the SLT and SLS solenoids. The first design is shorter than the later designs and requires the early SLT/SLS hold-down bracket (Figure 1). You can identify the early, short solenoids by the round hole in the slot where the bracket goes and the electrical connector that faces up (Figure 6). The first-design SLT/SLS solenoids are used on the valve-body casting with no letter.

The second-design solenoids are longer and the electrical connector faces up. The second-design SLT/SLS solenoids are used on the A-casting valve bodies (Figure 2).

The third-design solenoids are the same length as the second-design, but the electrical connector faces down. The third-design SLT/SLS solenoids are used on the B- and C-casting valve bodies. Both the second- and third-design SLT/SLS solenoids require the late hold-down bracket with the backward L at the bottom (figures 3 and 4).

Always install the hold-down brackets with the narrow end of the bracket facing up.

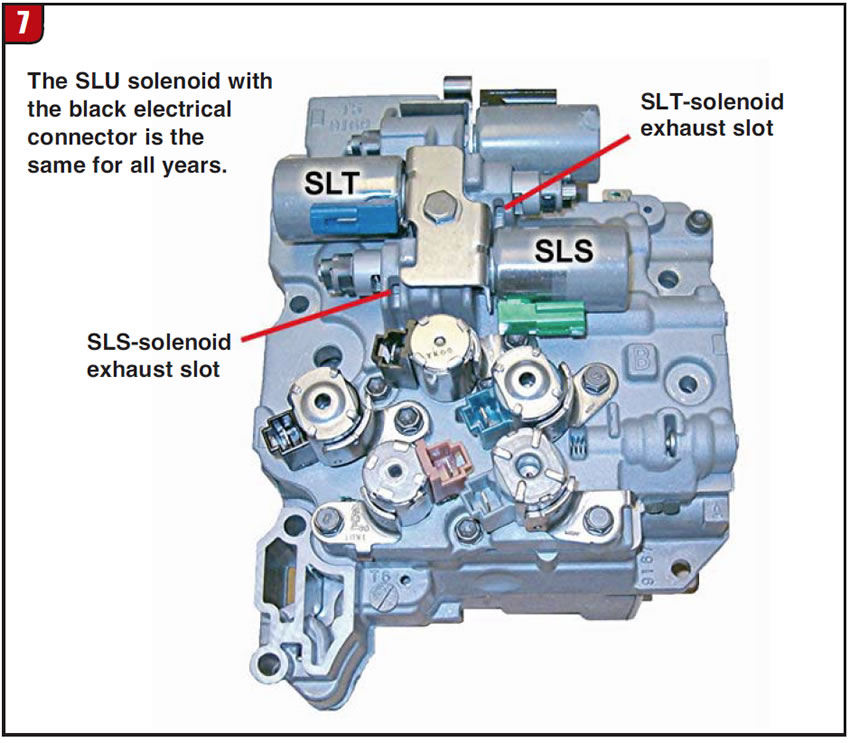

A good way to verify that the SLT/SLS hold-down bracket is installed correctly is to look into the exhaust slot for each solenoid to see whether the slot on the solenoid is aligned with the exhaust slot.

If the solenoid is blocking the exhaust slot, the bracket is on upside down or the wrong bracket is being used (Figure 7). If the exhaust slots are blocked, line pressure will go to maximum and the engagements and shifts will be harsh.

AW 55-50 valve-body-identification quick reference:

- Determine early or late valve body by using the letter code to the right of the S4 solenoid: No letter or A = early valve body, B or C = late valve body.

- Determine Volvo/Nissan or GM/Saab/Saturn valve body by the shape of the S2 solenoid.

- Determine 2005-up on B & C valve bodies by checking for a B5 control-valve spring (Figure 5).

- When installing the SLS and SLT solenoids, always install the hold-down bracket with the narrow side up (figures 2, 3, 4 and 7).

- Use the early SLS/SLT hold-down bracket with only the first-design solenoids that have the round hole in the snout (figures 1 and 6).

With this information you should be able to identify any AW 55-50 valve body.

Jeff Parlee is director of product support at ValveBody Xpress.