Technically Speaking

- Author: Wayne Colonna

- Subject Matter: Ree and Ree

- Issue: Bolt snapping

Technical Training

As one being involved with diagnosing transmission issues, developing technical information for seminars and bulletins as well as writing technical repair manuals, the one aspect of the transmission business I rarely think about is the R&R process. In Canada I hear them say “Ree and Ree” which is a nice quick way of describing the process of removing and re-installing the transmission. The lack of attention on this aspect of the transmission business does not indicate that it is insignificant. In fact, removing and re-installing transmissions is a critical aspect of the business. It is hard work and requires talent to do the job right.

Since my focus is always on transmission tech, I rarely get to see the wide variety of challenges that come with this type of work. While at WiWi’s Transmissions, a local shop here in Miami, one of these Ree and Ree challenges were brought to my attention. It may be an old challenge for those who do this work but it was new to me. Since I rarely get to present this aspect of the business I thought it would be a great opportunity to do so. It is possible that someone has yet to deal with this problem, making it a helpful piece of information.

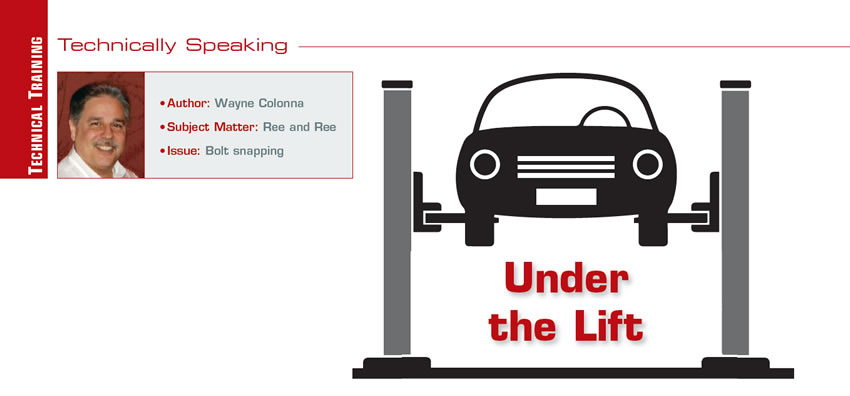

This has to do with a Chrysler Town and Country using the 62TE transmission. There is a 5-bolt cross member supporting the front transmission mount as seen in figures 1 and 2. The most forward bolt is in a very harsh environment (Figure 3). The threads of this bolt tend to get seized and will break when trying to remove it. Soaking it down with a rust buster and hitting it with some heat may help get the bolt out without breaking it. But there are many cases where it will still break.

One workaround is to loosen this bolt just slightly. Then, with the transmission properly supported, unbolt the mount and the other four cross-member bolts. Then swing the cross member to one side providing the necessary room to remove the transmission. One caveat that may be encountered doing it this way is that the bolt may not tighten up sufficiently. This will produce a vibration and a possible noise. Making a shim to go between the cross member and body frame will resolve that issue.

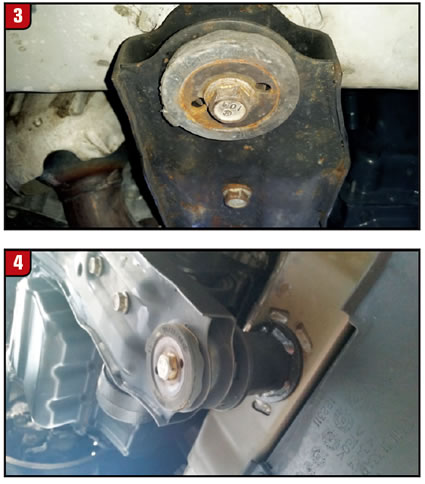

Some of these vehicles come with a custom body lift from the factory. The front bolt on this style cross member has a spacer as you can see in Figure 4. Interestingly enough, this style has not been “as” problematic as those without the body lift. But be cautious as they too are prone to bolt snapping.