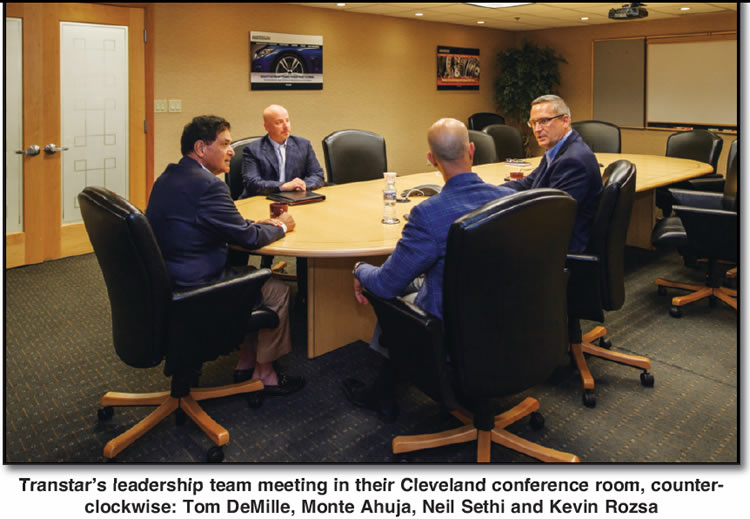

Transtar, the aftermarket’s largest distributor of transmission and related parts, was recently re-acquired by a group led by its founder, Monte Ahuja. The Transtar management team contains faces familiar to the industry who tell Transmission Digest that the company’s philosophy will return to what made it successful: Building relationships. Ahuja says that an evolving and increasingly complex industry creates new and different customer needs that are calling for what he calls “game changing” innovations.

“The transmission aftermarket distribution business is built from personal contact and relationships, which was my focus when I founded Transtar,” Ahuja says. “I pride myself on the relationships I developed and maintained with those customers for many years. At my retirement-from-Transtar party, I introduced my very first customer who was still our customer after more than 30 years. Developing relationships that lead to that level of loyalty has always been important to me.”

Ahuja – who serves again as Transtar’s Chairman and CEO – goes on to say that the success that Transtar enjoyed had always been based on the development of partner relationships with three groups: customers, employees, and suppliers.

“I recall developing a novel approach for Transtar early on; we always trained salespeople not to focus on getting an order, something that was very common in this industry. The salesperson would introduce himself to a new customer and say, ‘I don’t want your order; I want your business.’ There is a big difference between asking for the order today and creating a long term relationship of doing business together.

“We’re not going to merely supply parts to a shop customer. We’re going to understand his business and become solutions to the problems he faces. We have his best interest in mind. It’s not always easy for a customer to know the right parts to order, or the quality of those parts. It’s our responsibility to know the parts are correct for the job and are of the quality that the customer needs in order to stand behind his work. It’s a long-term relationship of doing business rather than a short-term transaction to sell parts.

“I’m proud to say that we have the best employees in this industry. We treat our people well and believe that when we take care of them, they will be able to focus their attention on making our customers be more successful. It’s something I have called the Transtar culture. It’s not something that’s written down somewhere; it’s an attitude of serving customer interests every day that is engrained into our tradition.

“As our business has grown, so has our appreciation for the total connection between our customers, our employees, and our suppliers. We acknowledge that our suppliers aren’t just a source where we get parts. We have always considered them to be our partners in business. Just in the past few weeks, I’ve had meetings with a dozen or more of our suppliers and I stress to each of them that they are our premium partners. Our survival in this industry depends on one another.

“When all three links of customers, employees, and suppliers are working together, then you are all successful. That philosophy is exactly what this team is focused on rebuilding in our company.”

Transtar’s President and COO, Neil Sethi adds, “Relationships run deep in our company’s DNA. Our philosophy was and will continue to be that there is nothing more important than having a Transtar salesperson establish a personal relationship with a customer and serving as the point of contact between our organization and that customer.”

Tom DeMille, Transtar’s vice president of sales and marketing, adds, “This philosophy puts us into the role of solving problems. We have more than 200 salespeople who focus on it every day. We look for ways that we can bring solutions to our customers that will add value.”

Ahuja believes that being solution-oriented is vital to the success of the industry. “We are constantly looking at the needs of our customers with a critical eye to determine how we can address these needs with technology-driven solutions,” he says.

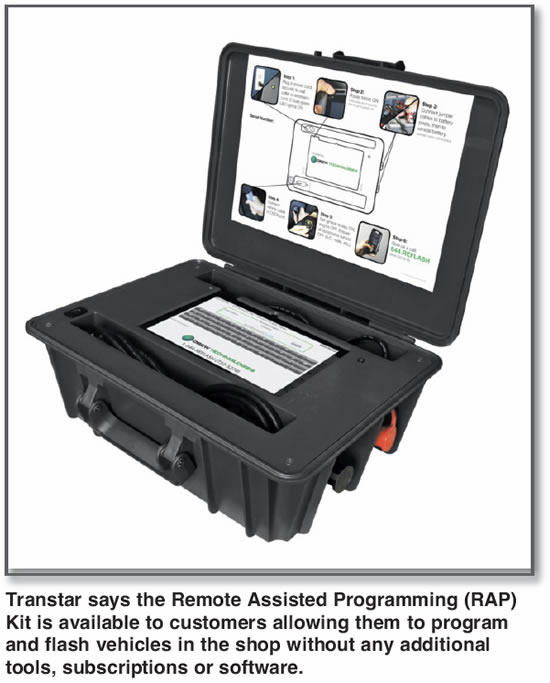

“A great example of this is the Remote Assisted Program (RAP) Kit,” DeMille continues. “Reflashing the TEHCM and other control modules in the vehicle is one of the biggest headaches our shop customers are facing. Up to this point, customers could either tow the vehicle to a dealer or wait for a mobile programmer to come to the shop with their equipment.

“Transtar’s RAP Kit is a self-contained module that’s available to the shops free of charge as long as they have two or more reprogramming events per month. It works and is as easy to use as dialing a telephone. The device we have programs beyond the transmission system; it does the entire vehicle.

“The RAP Kit is just one example of how Transtar is continuing to be forward-thinking in addressing not just the needs of the individual customer, but the needs of the industry at large.

“As a company, it’s our job to continually be evaluating the industry and determine what we can do to help our customers thrive in this ever-changing environment,” Ahuja comments. “This is a completely innovative approach to the distribution business – creating technology-driven solutions that improve all aspects of the business.

“We know that one of the most difficult parts of the ordering process is identifying the transmission and exactly what parts are needed for the rebuild. During our time away from Transtar, we spent more than two years developing a new technology called Transend, an online ordering system.”

“What evolved is a system that can support customers with instant and accurate parts identification,” Sethi adds. “The goal is to automate the parts-ordering function so that it solves the problem of accuracy and speed of fulfilling orders. We see ourselves leading the evolution toward facing the issues and the challenges that come about as the industry continues to change.

“Transend also includes the cataloging of Technical Service Bulletins (TSBs) that can be tied to a root word search. There are multiple ways to enter vehicle information: using a dongle via OBD II; inputting the year, make, and model; or the VIN. Customers not only receive the parts information they need to place an accurate and complete order, but also get pertinent TSBs from industry associations as well as OE and other manufacturers specific to the transmission type and error code. Transend is not just a parts ordering system. It is a content-driven solution that will holistically assist with the repair of the vehicle.

“This system will free up our salespeople, allowing them to deepen their focus on the customer relationship by having more time to become familiar with the individual businesses of those customers,” Sethi reports. “We are looking forward to releasing it to Transtar customers in early 2018.”

Transtar Vice President of Supply Chain Kevin Rozsa continues, saying, “It is so difficult with the proliferation of parts to just accomplish parts lookup for a job. Using a paper catalog is becoming a thing of the past. We are deploying a digital solution that makes it easier for our sales reps and our customers to be accurate when ordering parts.”

Ahuja adds, “If you look at a catalog today versus one from 20 years ago, it looks a lot like a phone book. Today, when you need a phone number, it’s at your fingertips on your iPhone – you no longer need a phone book. By the time a catalog can be assembled and printed, it has already become obsolete. Transtar’s Transend technology is the game changer for the future of Transtar and the transmission industry. Our customers will find phenomenal value in this technology.”

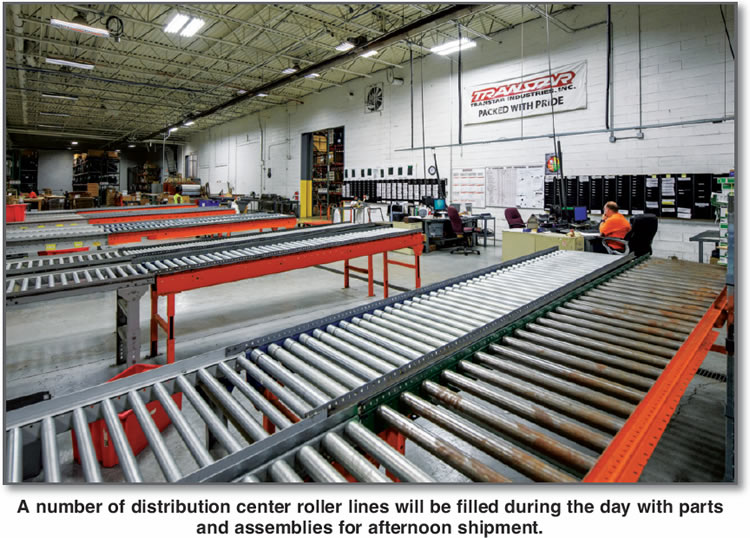

Ahuja sees Transtar as perfectly positioned to prepare the industry for future growth. He points out that the company operates four distribution centers and more than 70 local sales branches throughout the country.

“Our company understands the nuances unique to small businesses, which gives our customers a level of confidence in doing business with us,” Ahuja states. “Our philosophy during the 30 years we were growing Transtar was to leverage the benefits of a larger company so that we could provide a wide variety of high-quality products at a reasonable price, with a broad distribution network. But when it came to the branches and staff, we encouraged them to create close relationships with each customer as if the branch were a smaller business. And so, we created a sort of hybrid business that brings the advantages and benefits of the corporation directly to our customers.

“Our business and the industry may change, but our philosophy and culture will never change,” Ahuja concludes. “Our tradition is steeped in a philosophy that puts our customers and our relationships with them first. That is the key to our continued success.”