Technically Speaking

- Author: Mike Riley, Technical Editor

- Subject Matter: Implications of Mechatronics

- Issue: New dynos and valve-body testers

The purpose, challenges, opportunities

Last in a 3-part series

Diagnostics/Testing

Beyond the issues of hand-held tester capabilities relating to mechatronics is the current status of dynos and valve-body testers. On a dyno, the complete transmission is tested using the required software as it is with a valve-body tester. The VB tester however, has the additional challenge of a base plate that the valve body bolts to.

Unlike conventional valve bodies, a valve body with a TEHCM requires a specific software system to fire everything and record any necessary feedback. Even shifting a manual valve (if there is one) may need to be done by the machine, which is why valve-body-tester manufacturers have been adapting to the newer applications.

Valve-body testers of old were little more than a box with hoses, support plates and gauges that was manually operated due to valve bodies having few or no electrical items. As electrical components increased in number and complexity, so did the test machines by switching to a more computer driven operating system. PWM and linear solenoids require more than an on-off signal to function, and pressure switches must be monitored as well. Tester software evolved to sequentially energize the solenoids as needed and capture the resulting information – no more simple signals.

SuperFlow, manufacturer of Axiline dynos and valve-body testers, have continued to modify their equipment to conform to today’s applications. In addition to the countless valve-body support plates that have been produced over the years to accommodate traditional and TEHCM transmissions, SuperFlow had to develop more advanced operating systems as well.

The Axiline VBT 8000 valve-body tester has been in existence for some time now and can come equipped with the standard SuperShifter Pro software package (Figure 1).

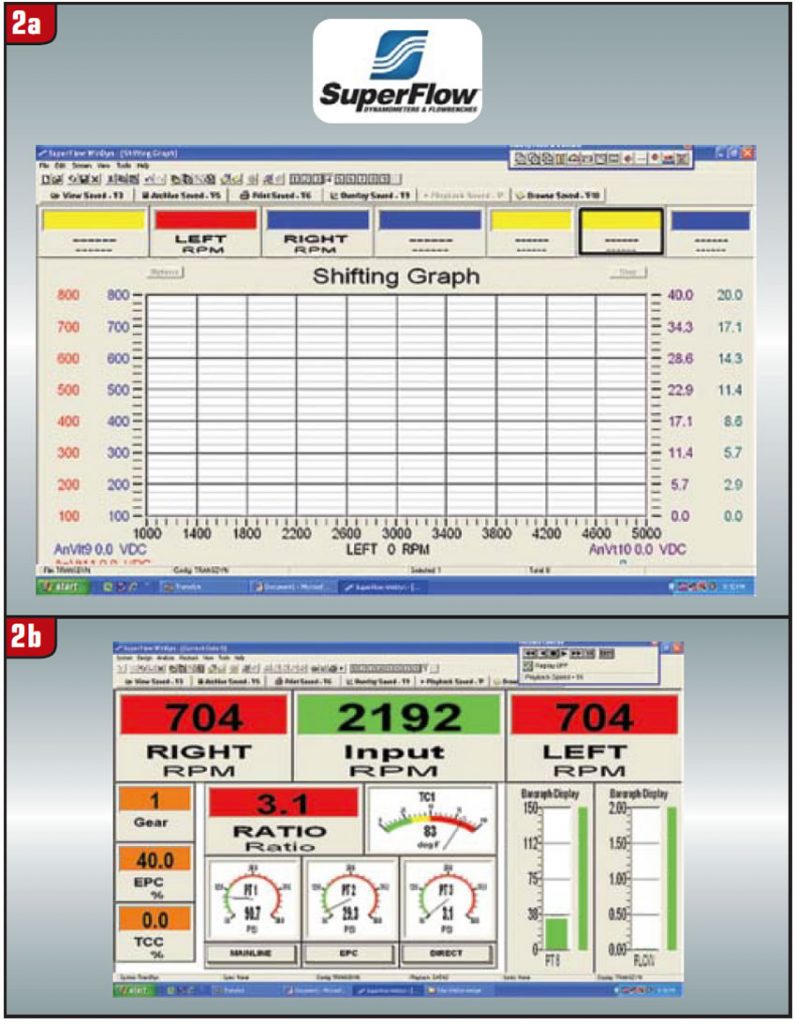

If needed, a more advanced software program is available to meet the demands of newer transmissions, referred to as the WinDyn Data Acquisition and Control system. The WinDyn will closely mimic real world conditions for better test results (figures 2A and 2B). The chart is a sampling of the WinDyn program.

Currently, mechatronics that can be tested with the VBT 8000 and WinDyn include:

- GM – 6T FWD and 6L RWD models

- VW – DSG (02E) models

- ZF – 6HP specific models (contact the company for a complete listing)

Beyond the transmission types listed, SuperFlow is not only developing test plates/software for other mechatronic models; it is also continuing to enhance tester capabilities to provide improved operation.

Another valve-body tester manufacturer that is stepping up to the plate with mechatronic transmissions is Fluidlogic. All base plates are configured to provide rapid valve-body changing, and the tester will reach the required fluid temperature very quickly. The tester comes with a three-year warranty as well.

The Fluidlogic S+VBT valve body tester comes equipped with an extremely durable and enhanced E-Zee shift/Enigma software system by Blue Reach Automation, which will enable precise control over mechatronic and non-mechatronic transmissions alike (figures 3A and 3B).

The tester will operate various field bus systems (CAN, K-line, etc). Currently, the S+VBT can accommodate the following units:

- GM – 6T FWD models

- VW – DSG (02E) models

- Nissan – RE5R05A models

- ZF – 6HP family of models (including Ford 6R models)

For a detailed listing of tester capabilities and applications for SuperFlow and Fluidlogic, visit the companies online at www.superflow.com and www.fluidlogic.com.

Remanufacturing

Valve body repair has become an industry unto itself in recent years. With valve or valve-bore wear issues as well as other failure areas escalating, shops today either address the needs internally by installing the required components or by replacing the entire valve body with a reman.

Valve body remanufacturers implement specific procedures based first upon the valve-body type. Next is to complete the repairs needed and then test the unit on a designated tester. Conventional valve bodies can be done this way, but what of a valve body with a TEHCM (mechatronic)?

With the transition to models that are controlled by an internal TCM comes a new breed of remanufacturer. Two such companies are SoftElectronic and a veteran in the business, Dorman Products. Although certain companies have been repairing computers for some time now, the combination of a valve body and plastic mainframe that contains a CPU (and in some cases, solenoids, sensors and switches) does provide a few more wrinkles.

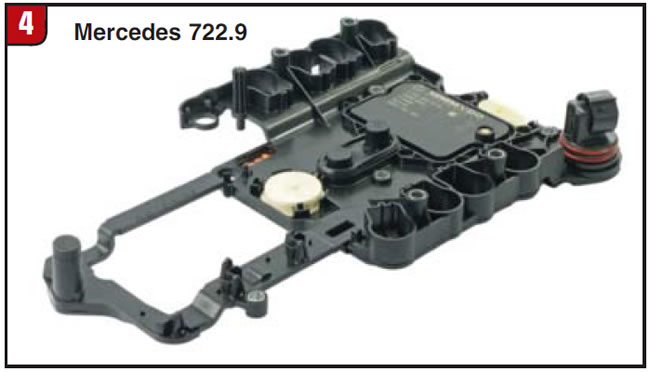

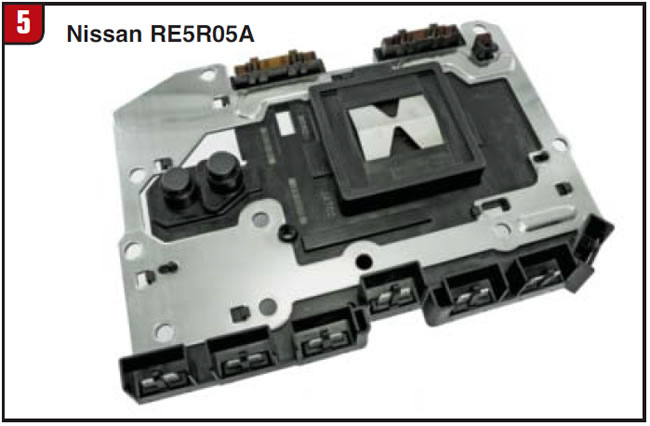

SoftElectronic has developed remanufacturing criteria on several mechatronic models, each of which present unique challenges with diagnosis, repair and programming. Transmission families with mechatronics that SoftElectronic currently service are: Mercedes 722.9, Nissan RE5R05A and VW 01J/6HP (for specific models, inquire as to availability).

Depending on application and whether the TEHCM is from the vehicle or not, SoftElectronic will follow a process of diagnosing, disassembly, cleaning, inspection, component testing and repair/replacement. Upon reassembly, the TEHCM will undergo a rigorous testing and reprogramming procedure to ensure proper operation.

For instance, when repairing a 722.9, a DTC P0718 may be detected, which denotes a TSS issue, while a P2759 will denote a TCC solenoid failure (Figure 4).

Repairing a TEHCM on a Nissan RE5R05A may require addressing a P1710 TFT issue or a P1841 pressure-switch failure (Figure 5). Regardless of the conditions, SoftElectronic will find and fix the concerns.

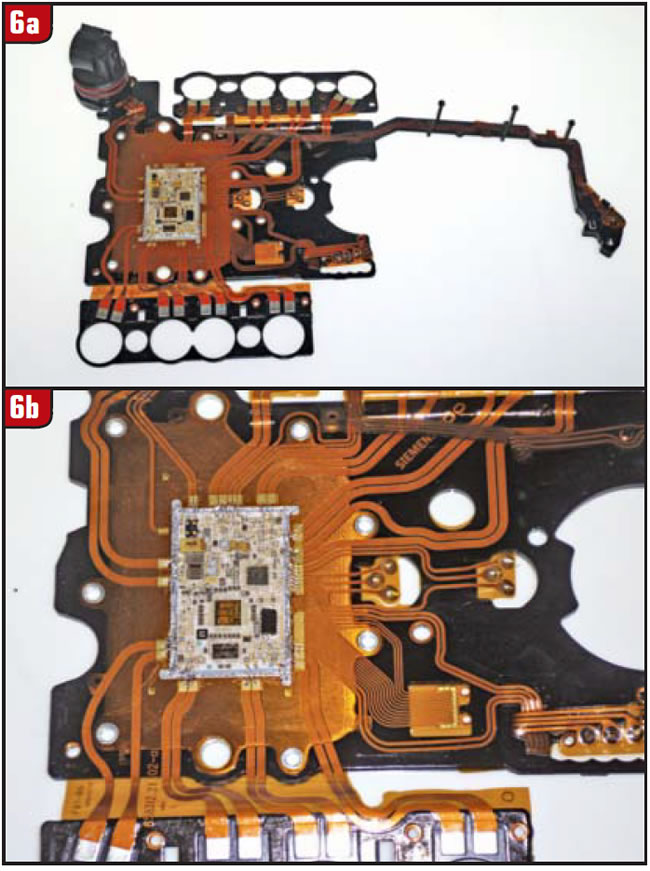

Repairing a transmission requires a certain level of knowledge and ability based upon the model, but imagine the challenge of dealing with the TEHCM itself as is illustrated in figures 6A and 6B. Hand tools and impact guns have little use in TEHCM diagnosis and repair. Chips and circuit boards, as shown on this 722.9 TEHCM, requires tender loving care.

Recently, Nissan has started sending dealer-replacement valve bodies, minus programming, which means that the shop may need a Nissan dealer program it or pay for a subscription to download the program onsite. SoftElectronic is also looking into this matter.

*Note: The vehicle can be started and driven in 4th gear to a dealer if needed.

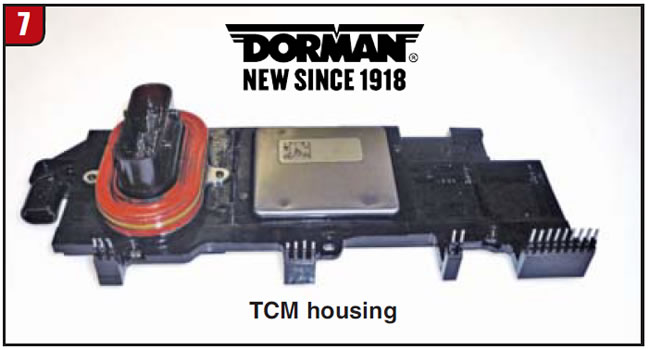

Dorman Products, a company with a wealth of history and experience has recently launched a line of remanufactured TEHCM units. As with all Dorman products, procedures have been developed to properly remanufacture, test and program all TEHCM applications before being sent to a repair facility.

Currently, Dorman offers remanufactured TEHCM’s to fit a variety of GM vehicles that come equipped with the RWD 6L45, 6L50, 6L80, and 6L90 family of transmissions, as well as FWD 6T30, 6T40, and 6T70 applications (Figure 7). This section contains the TCM.

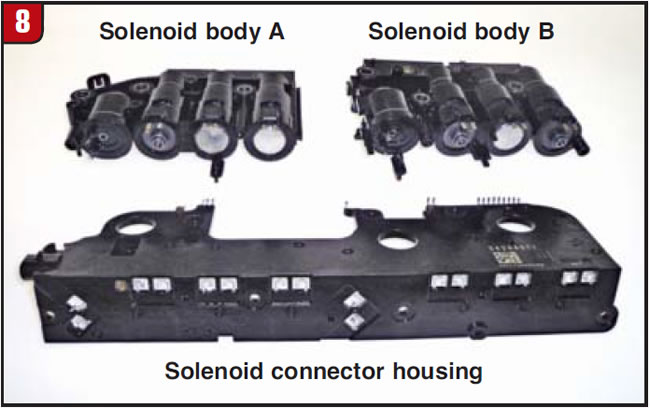

During the reman process, all TEHCM’s are initially tested to look for trouble areas or failures, and the units are run through a preliminary cleaning. Once disassembled, a secondary cleaning process is done to aid in component inspection (Figure 8).

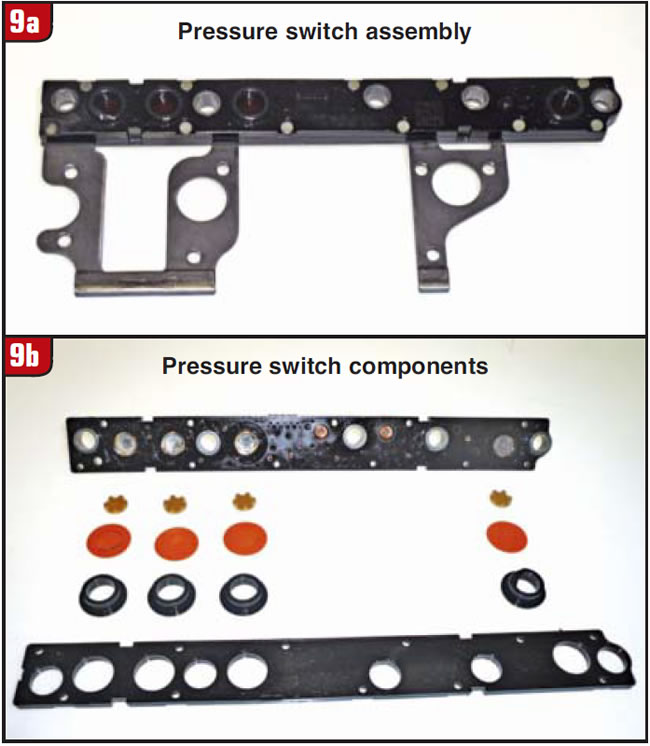

Once inspection is completed, failure components are replaced as needed, such as solenoids, while other items are replaced 100%, such as seals (including the valve-body cover seal), screen plate, pressure-switch film and pistons (figures 9A and 9B).

After assembly, the TEHCM is thoroughly tested for proper performance and will be preprogrammed with the vehicle’s VIN information, which eliminates the cost that the repair shop would have to incur. Free priority overnight shipping is also available, and all orders received by 5 p.m. EST will ship the same day.

Companies like SoftElectronic and Dorman are now providing the means to address mechatronic diagnosing and repair issues. Visit the companies at www.softelectronicus.com and www.dormanproducts.com.

Interchangeability

Throughout time, just changing one valve body for another could result in a big trick bag due to calibration issues. A valve body with mechatronics presents even more of a challenge. Depending on application, it may not be possible to swap the assembly. In some cases, installing another TEHCM unit can result in a number of issues including no start. There are models that can be interchanged with some additional programming, but it will require some investigation to determine which will. Websites can be a good source of information. Companies like SoftElectronic and Dorman may also be a good source of info, as well as possibly programming the replacement to fit.

Reprogramming

Whether a transmission has mechatronics or not, downloading updated info can be tricky and expensive. Make sure to follow manufacturer procedures, maintain proper battery voltage and follow up with recommended relearn or shift adapts.

Getting a handle on all aspects of mechatronic units will be necessary to compete in the marketplace, now and in the future. But it’s what the transmission aftermarket has always been able to do.

Special thanks to the following for their input and illustrations relating to segments of this article:

Chris Mann – SuperFlow Axiline Valve Body Testers

Andy Henney – Fluidlogic Valve Body Testers

Georgi Pantaleev – SoftElectronic Valve Body Remanufacturing

Jason Creighton – Dorman Products Remanufactured Complex Electronics