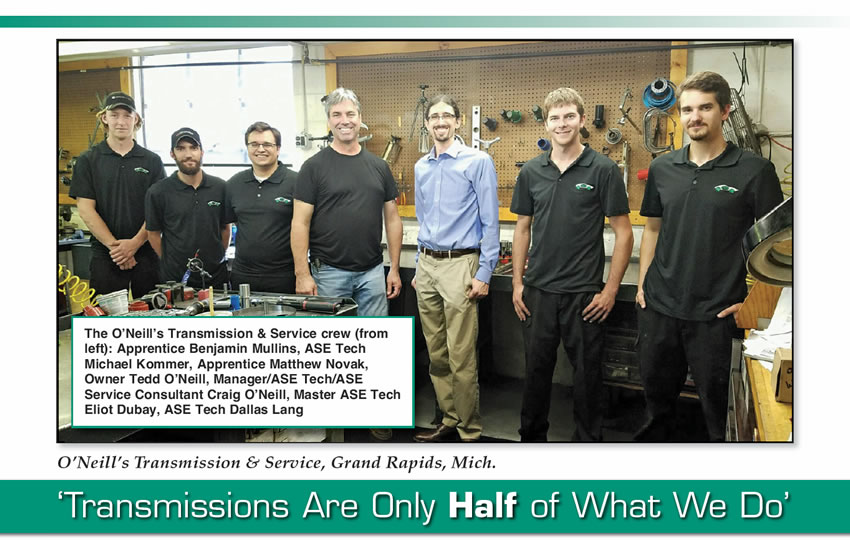

O’Neill Transmission & Service, Grand Rapids, Mich.

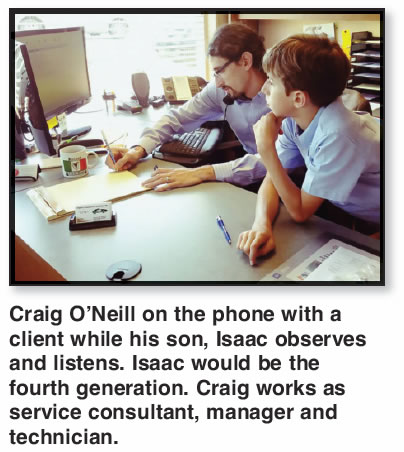

Facing technological and economic change, Craig O’Neill, the administrative leader of O’Neill Transmission & Service, aims to keep the third-generation shop profitable with a new business model for an industry he views as past its heyday.

Craig and his brother grew up in the shop of his father Tedd and grandfather Pat who founded the business in 1960.

As youngsters, the brothers went to the shop with their father. “We were drawn to this atmosphere because we were entrusted with complex things and were appreciated for our efforts. We were very helpful taking apart transmissions, cleaning them up. By the time each of us were 14, we were able to rebuild them – 4L60-E and stuff like that. It just snowballed from there.”

In high school, they worked as part-timers, and now they have two decades of experience, the most transformative period of the industry.

Craig noted that everyone now looks back to the ’70s and ’80s as the heyday of the industry, but the ’90s and early aughts also were rewarding.

“What we’re facing now is a new set of challenges that neither my dad or my grandfather’s generation had to face,” Craig said. “There’s an interesting complication because the business model doesn’t work like it needs to. We realized about 10 years ago that there was a significant change coming, with the pressures of remanufactured units becoming more popular. All of a sudden our typical wholesale accounts from all of our general-repair-shop friends – we stopped getting those calls for transmission referrals.”

Moreover, carmakers have been providing longer warranties, and when transmission shops see post-warranty vehicles, repairs often are not worthwhile.

Rock, hard place

Recently the shop replaced a dual-clutch transmission on a Ford Fiesta with 150,000 miles on it. The customer chose go with a used unit, Craig said. Rebuilding and replacing were not in his budget.

“The cost of these units is far outpacing what most people can possibly fathom spending on a vehicle repair,” Craig said. “And to base your whole business model on making that sale on a vehicle that’s got 150,000 miles on it – doesn’t matter how good a salesman you are, a point is coming where you can’t put that much on a credit card.”

Craig recognizes that remans are cheaper now. “How do you justify rebuilding a transmission that cost you more to build well than you can have replaced with a good long warranty?”

The brothers were aware of the changes. “We talked about them at length, because we have families, we have kids. We care very much about our futures,” Craig said, and he concluded that the circumstances are urgent.

“The average transmission shop that only does transmissions now is asking for trouble, and if they haven’t already started diversifying their business, and expanding their services offered, and developing that identity, they are going to find themselves way behind.”

Solutions

“Faced with all these things, we started to move toward general repair,” Craig said.

The process began a decade ago by adding a few new services, and it became a strategy during the past five years. One of the challenges was how to manage work flow for minor jobs and how to measure profitability, he said.

To gain more business skills, he attended a Bob Greenwood business class at a tech expo in Grand Rapids and later hired Greenwood as a business consultant.

It was a challenge, Craig said; it seemed easier to start a new business from scratch than to take over the shop and try to evolve it. In any case, the shop has become half transmission, half general repair. The shop focuses on drivability and also offers brakes, front end, suspensions, tires, alignments, wheel balancing. The shop has a Hunter Road Force wheel balancer.

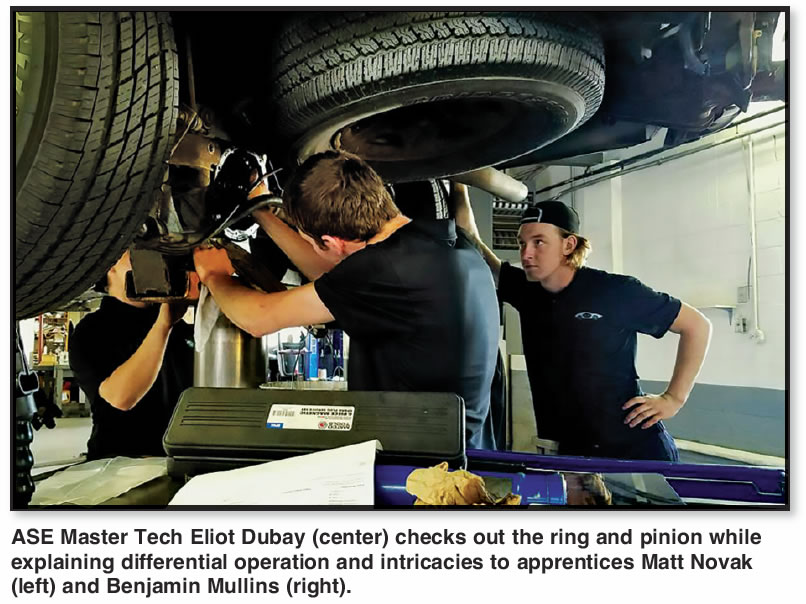

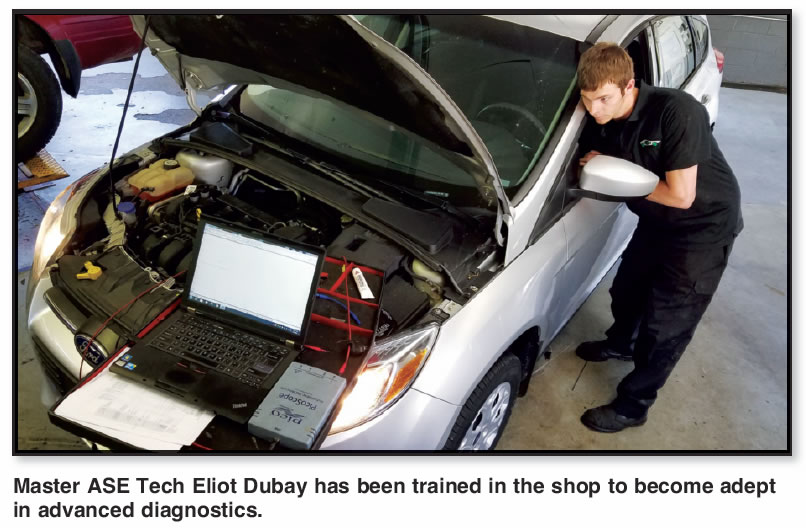

Meanwhile, Craig had encountered a shortage of technicians. In response, he created an apprenticeship program to educate two prospects. One of them, Eliot Dubay, began as an apprentice at age 20 and, five years later, has achieved ASE Master Tech status, focusing on diagnostics. The program works as a “training bond,” in which the apprentice receives training in return for a five-year work commitment, or pay for the training if the employee leaves early. Craig is also looking into subsidizing training at the local community college.

In another way that the brothers demonstrate their forward-looking orientation, Shaun, who has worked to become a first-rate diagnostician, has taken a job with a mobile diagnostics company. His employer allows Shaun to provide diagnostics for the shop when possible.

Craig acquired AutoVitals shop management software, and one of the apprentices took ownership of the program rollout.

Throughout the changes, the shop has maintained its dedication to customer service: “Being the shop that can be trusted to tell the truth,” as Craig put it.

Business goals

The business is moving toward a maintenance model, a one-stop complete auto center.

“Very gradually I expect transmission work in general to be less and less of what we do. As it is right now, transmissions are only half of what we do compared to the general repair, drivability and diagnosis. Two of my main technicians are not transmission technicians at all, aside from removal and installation.

Tedd, the main rebuilder, is aiming to retire, and this topic comes up frequently, Craig said.

The company is all-ASE-certified, including Craig as a ASE certified service consultant.

“My other goals are to be a multi-shop owner. I intend to open another location on the other side of town. While we have a big draw, that’s mostly for the transmission work. There are other people who would come to us for their routine maintenance if we were closer. I will do that eventually, but that’s not easy. I’m 34. I got little kids. I’m not sure how much time I want to spend Saturdays and Sundays trying to develop another shop at the moment.”

Shop notes

• 3-4 transmission jobs per week

• Equal amounts of work in rebuilding and R&R

• Business: 90% retail, and a couple of strong fleet accounts

• Customer radius: at least 30 miles

• Outreach: Call-in radio show Saturday mornings hosted by Shaun and another local shop owner.

• Specialty vehicles: Dodge diesel trucks, some performance vehicles.