TASC Force Tips

- Author: Tory Royce

- Subject Matter: 6T70/75 & 6F50/55

- Issue: Which replacement valve body?

Avoiding valve-body pitfalls with GM/Ford 6-speed automatic transaxles

Most builders swapping hard parts have learned that mismatching drive components in a transverse unit will result in a host of negative consequences. The wrong ratio sprocket(s) or carrier can result in TCC and ratio codes, along with converter and unit clutch slippage. Unfortunately, optional ratios aren’t exclusive to the final drive; they can exist in the valve body as well.

Case in point: the GM 6T70/75 and Ford 6F50/55 transmissions, which are used in a variety of popular cars and SUVs. The upper valve bodies in these counterpart units are equipped to regulate the apply rate of each clutch through specific valves, which are controlled by pulse-width modulated (PWM) solenoids. As often happens with PWM-controlled valves, the constant and rapid oscillation of the valve in the bore can rapidly wear the casting, which leads to pressure loss in the related circuit.

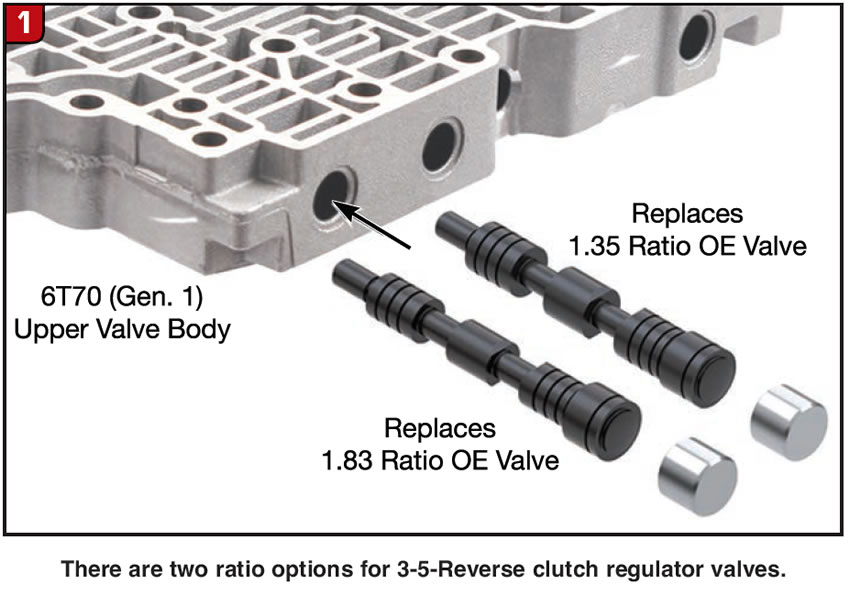

One area in the valve body that is frequently found to be worn is the 3-5-reverse regulator bore, which often causes flaring on the 2-3 and 4-5 shifts, as well as delayed engagements or slipping in reverse. As often happens during the life cycle of a transmission model after release, OE engineers determined that a calibration update was needed — in this case for the 3-5-reverse clutch apply rate. This affected the physical dimensions of the 3-5-reverse regulator valve and changed the control mapping. These changes occurred around 2009 in GM models and around 2010 in Ford vehicles. The aftermarket already has repair options available for worn bores, but when replacing the valve body, it’s important to be aware of which version you are working with to avoid trouble in the form of post-repair drivability problems (Figure 1).

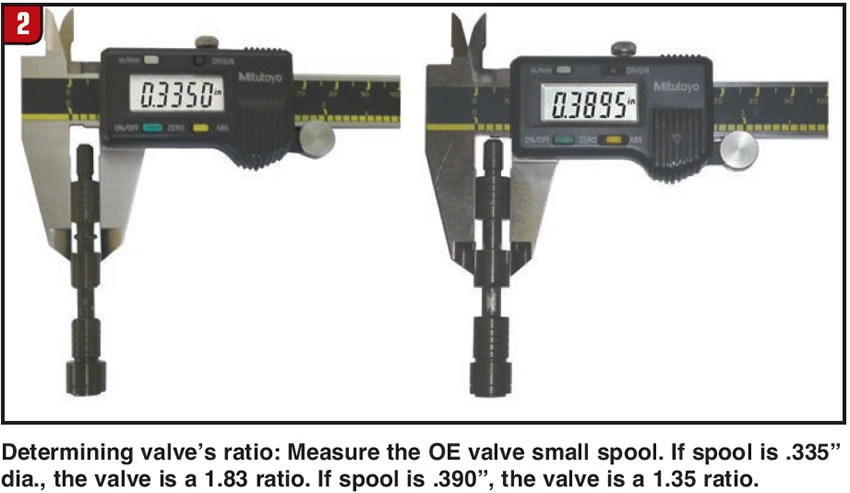

As part of the update, the inner spools were changed from a diameter of 0.390” (1.35 ratio) to 0.335” (1.83 ratio) on the spring end of the valve to increase clutch apply pressure (Figure 2).

To maintain solenoid pressure, the balance end of the valve remained the same. Additionally, casting and plate changes occurred at this time related to venting. You could pore over the different changes to figure out which ratio you are looking at, but the safest bet is to physically measure the 3-5-reverse valve to establish which version valve body you have on the bench.

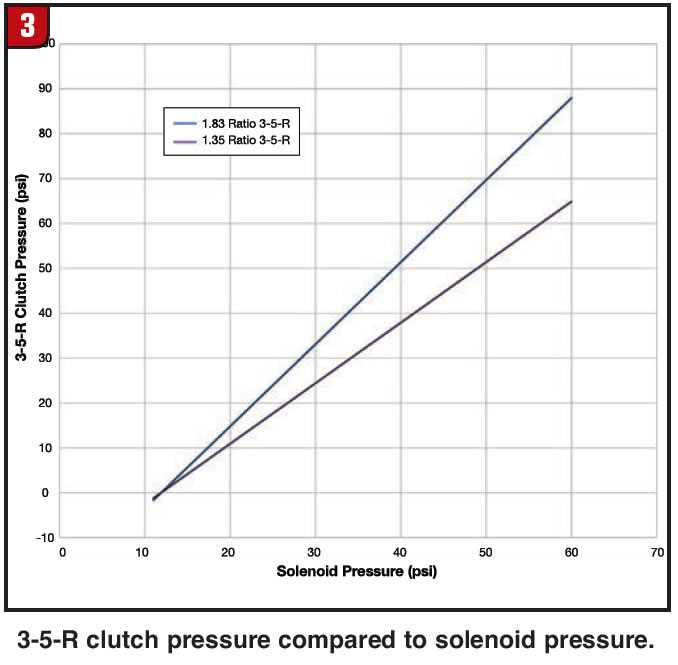

While small pressure tweaks are not uncommon with model year cycles, this change actually increased maximum pressure by over 20 psi on the high end of the pressure curve (Figure 3).

Because of this, identifying the correct replacement valve body is critical. In the event these are interchanged, shift feel and timing can noticeably suffer and result in the following symptoms:

If a 1.35 ratio valve body is used in a 1.83 application: 2-3 and 4-5 flare shifts

If a 1.83 ratio valve body is used in a 1.35 application:

- Harsh 2-3 and 4-5 shifts

- Binding 2-3 and 4-5 shifts

Taking the time to measure the 3-5-reverse regulator valve before obtaining a replacement valve body will ensure you don’t end up wasting time and money chasing a problem that could have been avoided. As long as the casting version you have is properly identified, replacing these valve bodies will be a painless operation every time.