Technically Speaking

- Author: Mike Riley, Technical editor

- Subject Matter: A750E

- Issue: Products – Toyota or Aisin

Beyond applications: Are items Toyota or Aisin produced?

Toyota has been producing automatic transmissions almost from the beginning of time achieving various levels of success in durability within their fleet. Over the years there have been incidents of Toyota developing transmissions for other car companies, domestic and overseas.

Toyota has also deviated from the norm in other ways by partnering with a rather large transmission producer, which they also happen to have a financial interest in, the Aisin incorporation. Aisin not only produces complete transmissions for Toyota as well as many other car companies, they also produce a wide range of components used around the world.

As demands on Toyota changed, more Aisin products, large and small, ended up in Toyota vehicles. A particular vehicle application could be equipped with a specific Toyota-produced or Aisin-produced item. Depending on the transmission type Toyota would actually reference two different part numbers for the same position as well as referring to which company actually produced it. A good example of this was during the development of the U140 / U150 transmission families concerning electrical components. For instance, a particular solenoid might be listed for the same position based upon what was used in production and the alternate would be listed as well. The upside is there was a noticeable difference in appearance between Toyota and Aisin. One set of a Toyota or Aisin produced solenoids would interchange while another set would not. There was also a potential difference in cost.

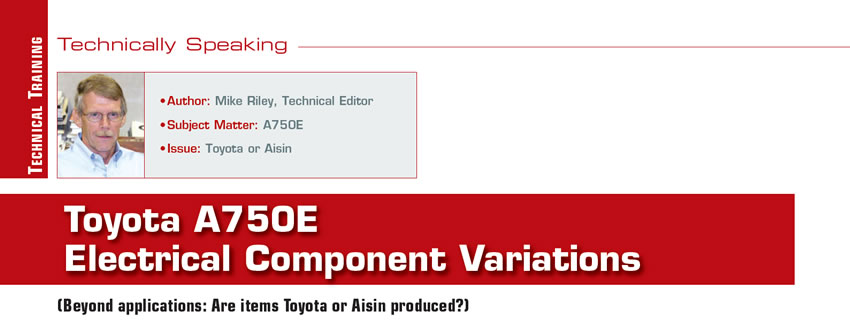

When Toyota launched the five-speed A750E, changes were already in the works for down the road applications, although the basic layout has remained unchanged. The valve body is fairly typical of other Toyota valve bodies relating to design and operation. There are seven solenoids, some linear and some on-off (Figure 1). Even the on-off solenoids operate differently with the S1 and SR positions being three-way and the S2 being a two-way design. The four linear solenoids also function different from each other.

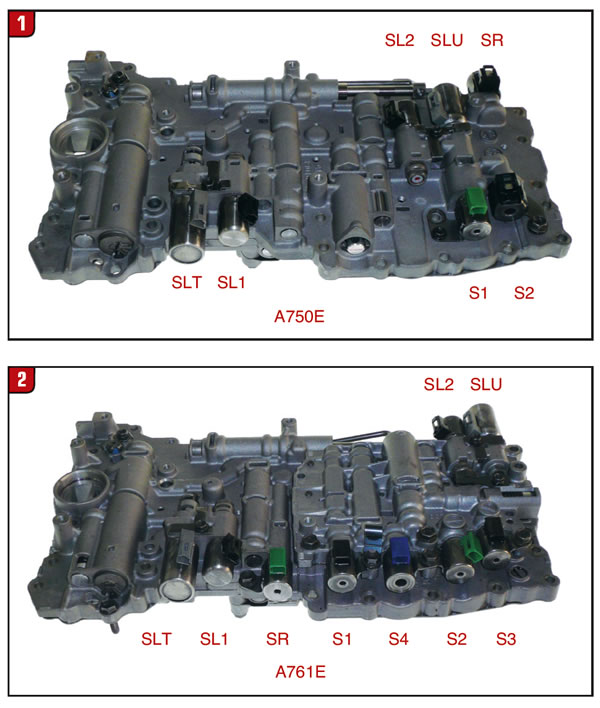

Toyota captured many of the attributes of the A750E during development of the six-speed A761E. The configuration of the valve body, for instance, is not too much different from the A750E body, considering the extra components to accommodate another gear and two extra solenoids bringing the total to nine (Figure 2). The two additional solenoids beyond the five-speed are the S3 and S4. One distinction between the A750E and A761E has to do with fluid temperature. The A750E has two TFT sensors whereas the A761E only has one. Changes to the A761E solenoids and harness as well as the valve body itself have been minimal over the years. Such is not the case with the A750E.

Electrical component changes can be relatively subtle or substantial based upon needs of the manufacturer. An item may be modified to contain production costs or benefit assembly processes, improve on calibration limits or increase durability, consolidate part numbers or upgrade to new technology. Changes to some of the solenoids in an A750E were more-subtle in nature but need to be addressed nonetheless. When the A750E was released in 2003 four of the seven solenoids had what would be considered an older-design electrical connector, whereas others came equipped with a newer-design connector. Why one solenoid was saddled with the old-style connector while another solenoid received the new thing is anyone’s guess, but when repairs are required, the shop needs to know which item to order.

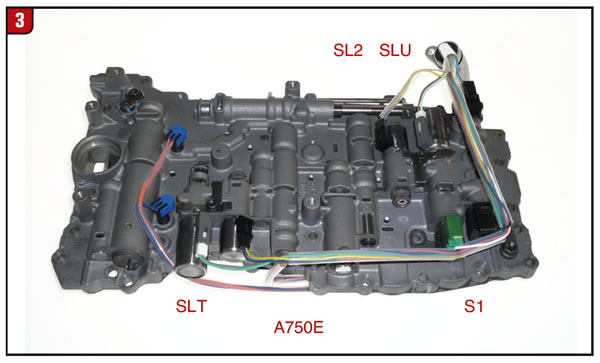

A starting point is to know which solenoids use what design connector (Figure 3). The four early-design solenoids that use the old connector are the S1, SL2, SLT and SLU. Although solenoid connectors and wiring harness terminals are color coded, that color is not always in sync as seen in the illustration. Note that the routing of the harness section connected to the TFT sensors illustrated is not as it should be for proper assembly. Always make sure that the two sensors are inserted into the proper valve-body ports.

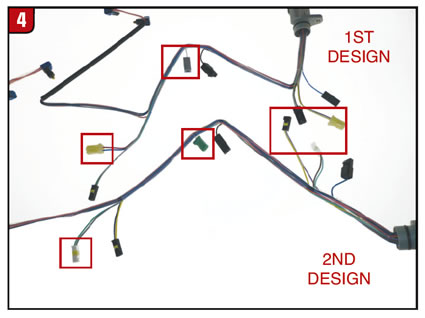

In addition to the solenoids having different part numbers between early design and late design is the issue of the electrical harness itself. Currently, there are two different harness-assembly designs (Figure 4). With the exception of the four specific solenoid terminals, the harness/case connector assemblies are almost identical and could interchange if someone wanted to cut and splice one of those terminals. The problem with all this is that Toyota did not implement the change overnight but rather it was phased in over a stretch of time based upon vehicle application. A Toyota 4 Runner was upgraded at a different time than, say, a Land Cruiser. Most of these changes occurred between 2004 and 2006. The part number for the first design harness is 84125-35130 and the second design harness is 84125-60650.

Rather the solenoid is internally grounded (one wire) or externally grounded by the computer (two wires) the electrical connector configuration could be the same to service both designs. The first-design harness terminals and solenoid connectors are somewhat different from the second design (Figure 5). The solenoid on the left of the illustration is the early design and the solenoid on the right is the later design. Both are pin-type terminals, rather one wire or two although the S2 and SR solenoids actually use a good old spade terminal in all applications. The later-design terminals are a little bit harder to push out of the connectors than the early design.

Lastly, another wrinkle exists when dealing with Toyota solenoid applications: Which is the manufacturer: Toyota or Aisin? The size of the body of the solenoid, at times, is a good indicator (Figure 6). There is a noticeable difference between the linear solenoids illustrated in Figure 5 and Figure 6 and there are applications where a small can or large can could interchange. The best way to determine that is by part number within the Toyota parts catalog.

When Toyota first released the A750E they actually used different part numbers for the SL1 and SL2 solenoids, but when the changeover to the second design was implemented one common solenoid was chosen for both positions, which happens to be the solenoid on the left in Figure 6. That really helps out the war effort. At least the A761E electrical is fairly consistent.

Whenever a repair is made on the A750E concerning a valve body, solenoid or harness, make sure of the design level to avoid downtime.