Tech To Tech

- Subject: No start

- Vehicle Application: 1993 Eagle Talon 2.0 turbo

- Essential Reading: Diagnostician

- Author: Jeff Bach

Diagnosing and repairing cars can take on a quirky and sometimes creative turn during tough economic times!

Tough economic times bring with them differing circumstances for different industries. For those of us in the independent automotive-service field, we may be seeing more and more repairs being attempted by less- and less-qualified technicians. It seems like there is an endless supply of advice to help automotive-service “newbies” figure out their car’s technical woes, thereby saving them the time and trouble of taking a car to a “professional.”

As our local mail-delivery guy once said, “If a mechanic can figure it out, surely I can do it.” It’s been my experience that there is a persistent absence of respect for the training, experience and equipment needed by today’s technicians to be able to actually diagnose some of the problems encountered on modern automobiles.

Along with our normal percentage of problem jobs, we’re also seeing those do-it-yourself (DIY) jobs that DIYers abandon after they have had no luck. These DIYers then turn to the mechanic working part time at home, and when that doesn’t work they go to the cheapest shop they can find, and when that doesn’t work their car finally arrives at our shop. As a result of economic times, we are seeing a new wave of problem cars with issues that we don’t typically see.

Some common problems we’ve seen lately are multiple modules blown or not communicating because someone worked on the car with the key on and disconnected the battery, hooking and unhooking a battery charger. I’ve even seen a recent resurgence in the charging-system quick check of disconnecting the battery while the car is running to see if it is charging. By the time we get these cars in the shop, in many cases there are multiple problems and possible modules replaced that aren’t programmed, loose-fitting connector pins etc. I was recently asked to look at just such a car by a friend from another shop, who got the car from the mechanic friend of the owner, who tried doing his own diagnostic work.

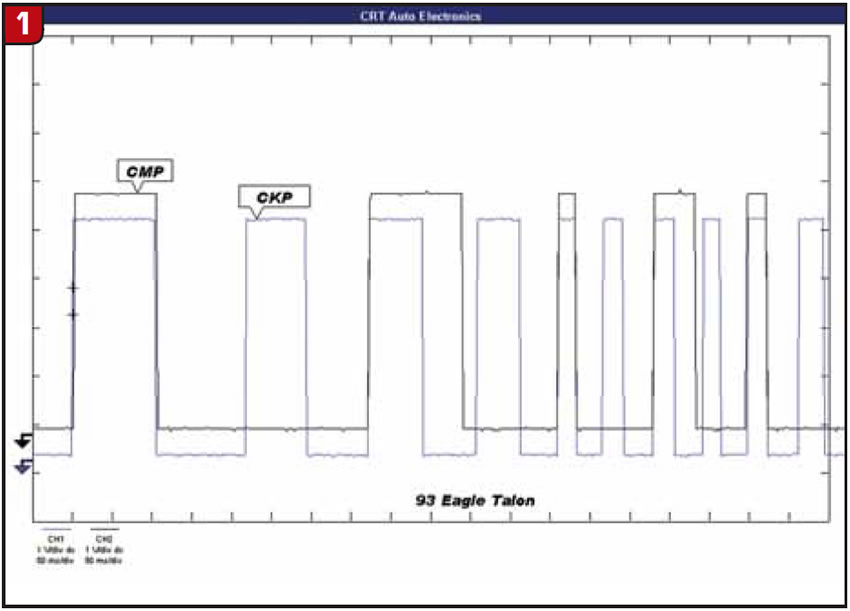

The car is a ’93 Eagle Talon 2.0 turbo that will almost run. I did a few preliminary looks at power and grounds, then a code check, which turned up no ills so far. Two of the plugs looked slightly rich and two were lean. Compression and basics were good. I printed a pin chart of the electronic control unit (ECU) and started getting voltages and scope signals – beginning with the most basic – after verifying power and ground circuits. These would be the crank-sensor and cam-sensor signals. Figure 1 shows those results captured on the scope.

I tried to find a known good signal in my database and couldn’t. I then searched the iATN waveform library to no avail, which didn’t surprise me in either case, since this car gets both of these signals from a Hall-effect distributor, which would be unaffected by cam/crank-phase relationship. I then checked the coil firing, which was good for all cylinders. The next check revealed that the injection system was working on only two cylinders. I used the current probe to verify that only two injectors (one group) were being triggered by the ECU. The voltage at the ECU for the injectors was present and the resistance check showed them to be correct. I thought possibly the ECU monitored the current level with a short test pulse and perhaps wouldn’t allow injector current if it saw too rapid a current buildup, as happens on some later models, but this was not the case.

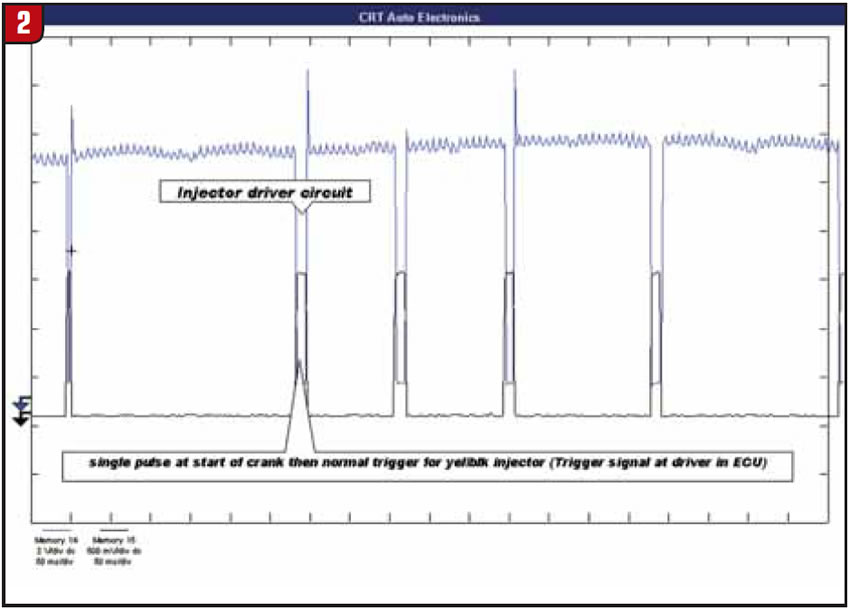

Figure 2 shows the waveform for the working injector group along with the trigger signal. I took the cover off the ECU to look for presence of the much-touted leaking capacitors that this particular generation of ECUs is known for. I then traced the trigger signal back to the chip on the board that triggers the driver for the injectors.

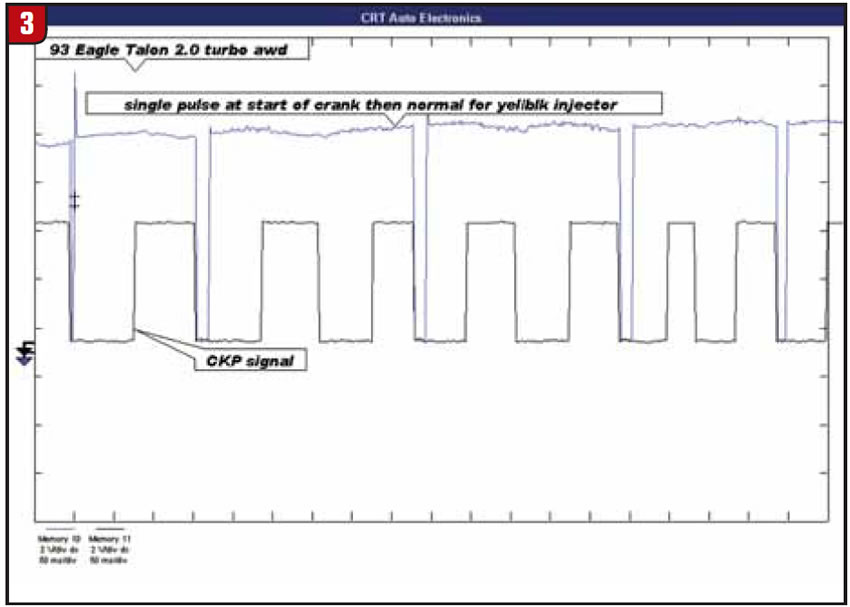

There is a single pulse at the beginning of the crank cycle, then the injectors begin pulsing regularly with the cam-position (CMP) signal on the working group. The ECU was supplying the first pulse on the non-working group and then nothing. My next shot was from the injector signal against the crankshaft (CKP) signal (Figure 3).

There was no pulse for the other injector group. Since this was a distributor system with both CMP/CKP signals present, all the power and grounds present, and injector circuits intact and resistances good, I made the call that the ECU must be at fault.

This was the dreaded diagnosis, since it was the most-expensive part in the “guess chain” and all the other parts had been tried. I found a rebuilt unit reasonable enough and ordered it. When the part arrived, I plugged it in and cranked the engine. Much to my dismay, it didn’t start. I did a few initial checks and started to get that sinking feeling. The car was doing the same thing – firing only two injectors. I knew the odds of having a second ECU doing the same thing were not good. I started rethinking the possibilities.

I decided that there was a possibility that the CMP/CKP correlation could have an adverse effect if, say, someone did not assemble the distributor correctly. I decided that it might be prudent to take a closer look into it. I pulled the cover off and took out the screw that held the trigger wheel. The trigger wheel is actually two separate wheels pinned together (Figure 4).

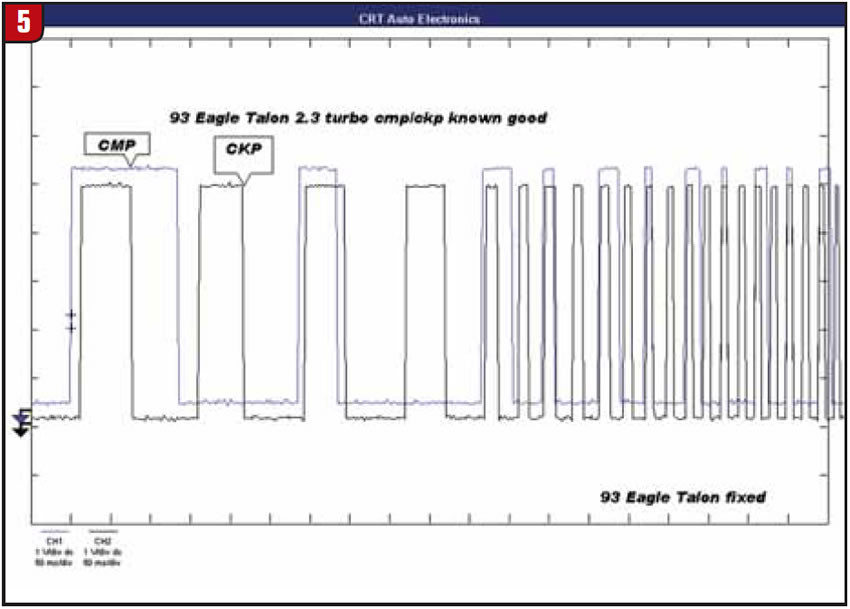

Turns out that the roll pin was not quite through the second wheel and it was slightly off from its original position. I moved it into the correct position and reassembled the distributor. The car fired right up as if it was just turned off. I was pleasantly surprised. I took another shot of the CMP/CKP-sensor signals for comparison and perhaps a reference. I doubt that another technician is likely to run across this problem, but who knows? The waveform is shown in Figure 5 for the correct correlation between the CMP/CKP signals.

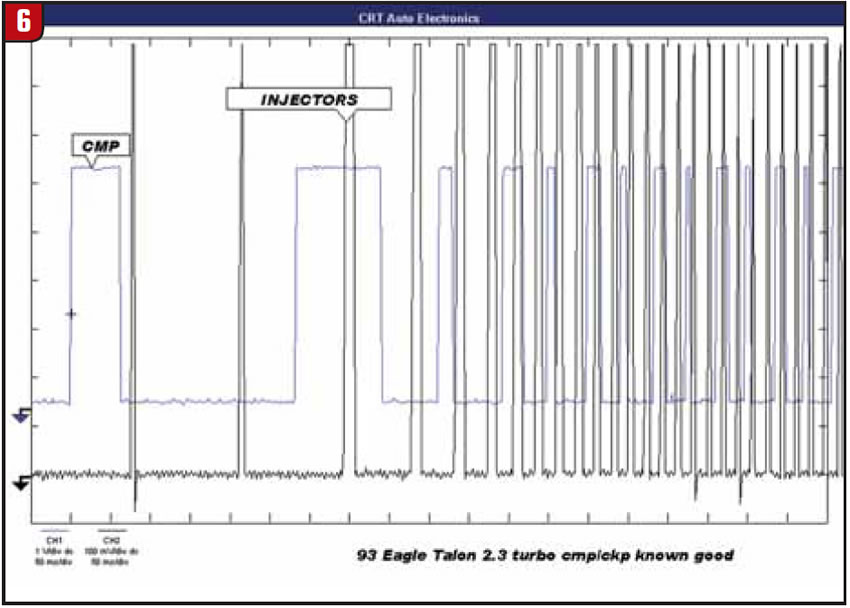

The difference is surprisingly slight, but it’s enough to create a headache for a few people. I had to get one more shot of both groups of injectors working. Figure 6 shows the CMP signal on Channel 1 with the injector current for both groups on Channel 2 as I went from cranking to running.

With the adventure that this car has been on, it’s hard to say what the original problem was. I understand people trying to save money by doing things themselves in trying times, but most people who will try to tackle car problems wouldn’t dream of taking apart their furnace or trying to put a belt on a washer or dryer. They call a furnace man or an appliance-repair guy.

Hopefully, someday automobiles will at least gain the respect that DIYers afford to their dishwasher.

Jeff Bach is the owner of CRT Auto Electronics, an ASA-member shop in Batavia, Ohio. For more information on this topic, contact Bach at (515) 732-3965. His e-mail address is [email protected] and his Web site is www.currentprobe.com.

This copyrighted article is reprinted with the permission of AutoInc., the official publication of the Automotive Service Association (ASA). To learn more about ASA and its commitment to independent automotive service and repair professionals, visit www.ASAshop.org or call (800) 272-7467.