TASC Force Tips

- Subject: Diagnosing external problems that affect transmission operation

- Vehicle Applications: 1995 Ford Bronco, 2001 Dodge Caravan

- Essential Reading: Shop Owner, Center Manager, Diagnostician

- Author: Dan Tucker

Running a transmission shop has really changed over the past 30 years. The biggest challenge I have seen in the last few years is determining whether the problem causing a customer’s compliant is inside the transmission or elsewhere in the vehicle (or should I say, a vehicle control system?)

Many shops diagnose the compliant, and if they find the problem to be outside the transmission they “punt” the job. Our shop took a little different approach years ago and established a motto: “We will fix your transmission complaint from the battery to the tires.” It seemed like the American thing to do, to be a “one-stop, get your transmission problem fixed and not be sent back and forth from shop to shop” shop. Although it felt like the right thing to do, I can recall many times we have found ourselves off on an island and praying for a miracle fix.

Who would have thought years ago that we would glue a rearview mirror back onto the windshield to get a transmission back to shifting? I know that sounds ridiculous, but that is just one example of a real fix for a real problem we have encountered in our shop.

To briefly cover the rearview-mirror repair, I will explain. The vehicle was a 1995 Ford Bronco. The customer complained that it quit shifting all at once. You know the type: “It is stuck in first gear.” While the customer was filling out the paperwork to leave the vehicle with us, he asked whether we could glue his rearview mirror back onto the windshield while we were fixing his transmission. We have all seen an inside rearview mirror unglued by the hot sun before. I explained to him nicely that we didn’t do that type of work. He said “Not a problem; I’ll get it done later at a general-repair shop.”

After the customer left, I hopped into the vehicle and pulled it up in a bay, noticing that the speedo cluster’s odometer was not lit up, nor was the speedo working. I grabbed a scan tool, and, sure enough, it had a 452 code for loss of speedo signal. I thought blown fuse, because the odometer was not working. I checked the fuse and it was blown.

Next stop was to see what else is on that circuit. Fords are bad about ‘piggy-backing’ several things on one fuse, and this was no exception. I looked at all the things on the same circuit as the cluster: 4WD shift lock, electronic shift-control module, air-bag module, and then I saw compass/outside-temperature module. I looked on the floor, and, sure enough, the rearview mirror that the customer had asked me to glue back on had a compass in it.

I looked up in the headliner, and the wiring that used to run to the mirror was naked and had a spot that appeared to have shorted to ground. Most likely, it shorted while the mirror was hanging by the wires, before it fell to the floor. I repaired the wires and – yes, you guessed it – ordered a rearview-mirror glue repair kit and glued the rearview mirror back in place. I popped a new fuse into the fuse box and the vehicle was fixed.

The hard part was humbling myself and calling the customer to tell him we had found his problem and corrected it – and, oh, by the way, while we were at it we went ahead and glued the rearview mirror back to the windshield, because that was what had caused the problem.

We had a similar job come in this week, but this vehicle’s owner had already been all over town trying to get it fixed. I used to like these kinds of challenges, but my financial adviser has warned me that “punting” jobs like this might be more profitable.

The vehicle was a 2001 Dodge Caravan. The complaint was that it was stuck in second. The TCM would not communicate with the scan tool. We checked the transmission relay, and the TCM was not sending voltage to the relay. I had one of the guys lift the vehicle so we could drop the TCM down and test further.

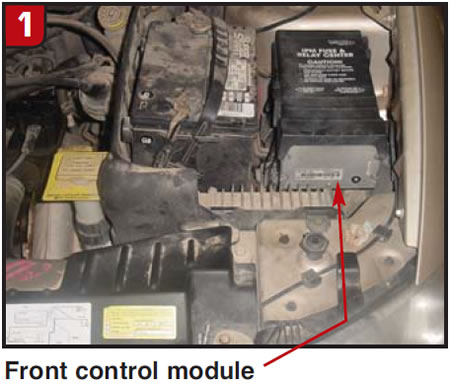

This TCM is in a bad environment. It is under the battery and in front of the driver-side front wheel. It is a high-failure part, with battery acid and water getting into it. We tested for power and ground at the appropriate pins. The TCM had grounds and battery voltage, but we didn’t get any ignition-voltage signal at pin 11. I noticed that the wiring diagram listed the #11 pin at the TCM as “FCM off-run-start” instead of the normal “ignition” source we are used to seeing.

I thought, what is FCM? I did a little research and found out it was front control module – a simple computer that controls most of the body circuits at the front of the vehicle. Now, what does it have to do with the transmission? The FCM has the responsibility of sending 12 volts through the integrated power module (IPM) to the TCM when the FCM detects that the driver has turned the ignition switch on. Sort of a long way around for getting the ignition voltage to the TCM, but that is the way it was designed.

We checked the IPM (what most of us think of as the fuse/relay box), and it tested OK. We ordered an FCM, installed it and flipped the key on, and it sent 12 volts to pin 11 on the TCM. The TCM booted and the van was as good as new. This is an example of testing a system that is similar to those we have worked on many times before, only to find a completely different fix from what we expected. As vehicles change and we see more CAN (controller area network) systems, we will continue to be forced to think outside the box.

Dan Tucker is owner of Tucker’s Transmission in Pine Bluff, Ark., and a member of the TASC Force (Technical Automotive Specialties Committee), a group of recognized industry technical specialists, transmission rebuilders and Sonnax Industries Inc. technicians.

©Sonnax 2009