Technically Speaking

- Author: Wayne Colonna, Technical Editor

- Subject Matter: 41TES and 42RLE-VLPS

- Issue: “Line Pressure to High” code P0869

Five possibilities are listed for reasons that P0869 will set

The 41TES and the 42RLE-VLPS are known to produce a “Line Pressure to High” code P0869 due to defective TCM/PCM’s immediately after a 2-3 shift. When this call comes in on our help line, we ask the tech involved to run some tests so we can be certain that a defective computer is the cause. Being a pattern failure, a repair tech can be as costly as buying a computer that doesn’t fix the problem and makes for a bad day.

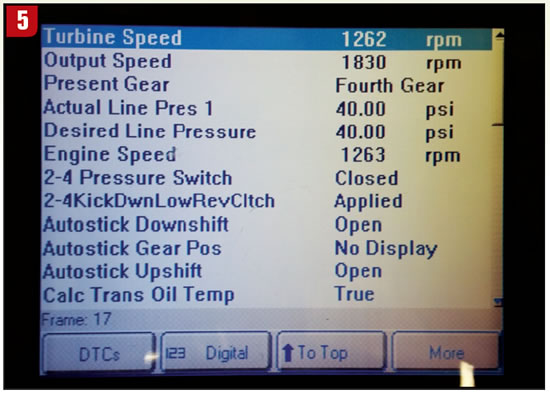

The strategy of the VLPS is used to lower line pressure at various times in a drive cycle. The duty-cycle range with which the computer operates this solenoid is as low as 5% to as high a 62%. Minimal influence will take place on the line pressure at 5% while maximum influence takes place at 62%.

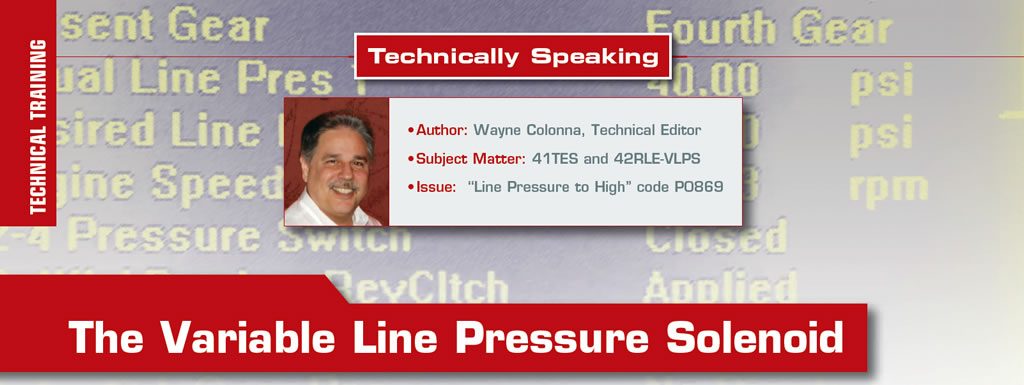

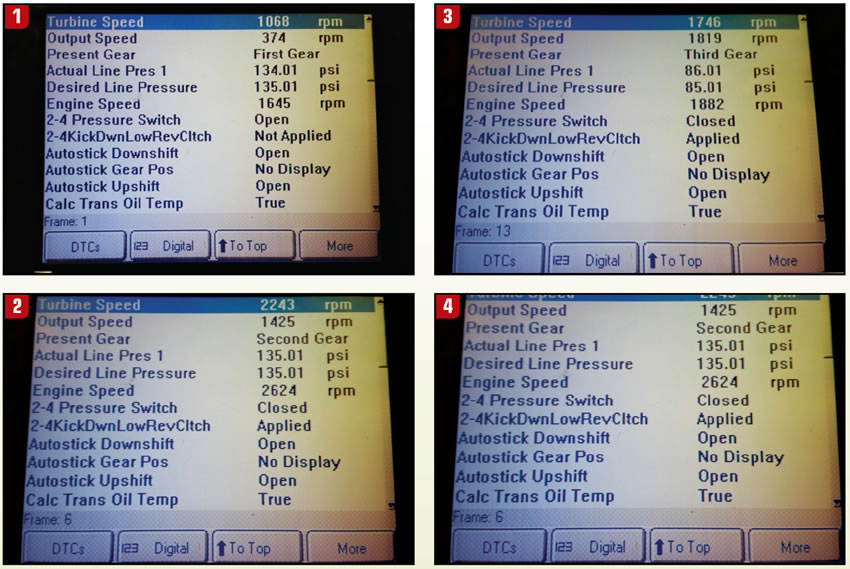

Desired line pressure and actual line pressure can be observed with the use of a scan tool. Desired line pressure is the computer controlling the solenoid via duty cycle. The actual line-pressure parameter is what the line-pressure sensor reports back to the computer to verify solenoid activity. When both the solenoid and sensor are working correctly, these two parameters should be very close to each other. First and second gears run around 135 psi (figures 1 and 2). For third and fourth pressure is dropped to around 85 psi (figures 3 and 4). Once lockup is fully applied, line pressure is commanded to drop even lower (Figure 5).

Comparing this scan-tool data to the computer’s duty cycle command using a meter, about 5% duty cycle will be observed while idling in drive with the brake applied (Figure 6).

Once the vehicle begins to move, duty cycle bounces around throughout first and second gears, but once the 2-3 shift occurs, duty cycle ramps up to 25% (Figure 7) and line pressure drops to approximately 85 psi. When the converter clutch applies in fourth gear, duty cycle climbs to approximately 30% (Figure 8) at which time line pressure drops again.

This is very interesting when you compare this to how the 41TE and 42RLE works without the line pressure solenoid and sensor. The fixed line pressure in first and second gears runs between 120 to 145 psi. When a shift into third takes place, the overdrive solenoid is used to apply the OD clutches. This same pressure is also routed to the pressure-regulator valve to lower line pressure down to approximately 85 psi for third and fourth gears. This 2-3 shift pressure drop is now controlled by the line pressure solenoid for the 41TES and 42RLE-VLP transmissions.

Once duty cycle jumps to 25% to lower line on the 2-3 shift, the computer looks at the pressure sensor to see if the line pressure had dropped. If the sensor does not show a decrease in pressure, P0869 will set. The cause for this to take place can be one of the following possibilities:

- A mechanically failed VLPS

- A mechanically failed pressure sensor

- An electrical problem with the pressure sensor signal

- A pressure regulator valve problem

- A computer that thinks it is duty cycling the solenoid when it is not

The quickest way to know if the computer is malfunctioning or not is by placing a meter onto the variable line pressure solenoid to monitor duty cycle. Set the meter to observe negative duty cycle, which shows solenoid “On” time. In other words, the more time the solenoid is being grounded, the more time it is on where it lowers line pressure.

If it does not jump to 25% duty cycle on the 2-3 shift, you have a defective computer. If it does jump to 25%, the first four possibilities are now in play. Placing a line pressure gauge would be the next step. If line pressure does not drop on the 2-3 shift with a 25% duty cycle command, the solenoid has failed mechanically or there is a problem with the pressure regulator valve. If the pressure did drop, there is a problem with the sensor or sensor signal.

In the beginning of the article, it was mentioned that the VLPS can be duty cycled as high as 62% (Figure 9). This would be the computer’s lowest line-pressure drop command that it’s programmed to do. This can be observed on a coast 2-1 downshift. This is done to smooth out the 2-1 downshift bump the 41TE and 42RLE without the solenoid is known for.