Up to Standards

- Subject: Determining whether a problems is in the transfer case

- Essential Reading: Rebuilder, Diagnostician

- Author: Mike Weinberg, Rockland Standard Gear, Contributing Editor

The most critical part of any repair work is locating the cause of the problem that causes the customer complaint. Be careful in this day of extreme economic pressure not to be too quick to remove a unit, especially a transfer case, before being positive that it is the source of the problem. We all need more work, and it is much too easy to remove the transfer case from the vehicle without inspecting all the other components that could be the source of the problem, such as driveshafts, yokes, differentials and driver bad habits.

First off, once you remove the unit, the vehicle is now undrivable, which loses you the only true dyno you may have. This is absolutely critical in issues related to noise, vibration and harshness. If you remove the unit and inspect it internally and find no broken or damaged components, how do you “see” a noise? This leads to a lot of wasted labor, frustration on the part of the technician and a bunch of time wasting phone calls trying to get some diagnostic help.

There are no moving components in any automobile that do not generate noise and vibrations, and the manufacturers spend a fortune on keeping those noises isolated from the passenger compartment. If you stand by any highway, you will hear a tremendous amount of tire noise from passing vehicles, as tires do make noise in contact with the pavement. However, the drivers of those vehicles do not hear that noise if the tires are stock and the windows are closed. We are going to discuss here some of the problems and misconceptions that create wasted labor and lost earnings involving the diagnostic approach used in handling transfer-case problems.

Noises on the lift

We get endless phone calls on our customer technical hotline regarding noisy transfer cases while the vehicle is on the lift. 99% of all transfer cases will sound noisy if operated on a lift. In the first instance, all component noise is louder when you are under the vehicle with the wheels in the air. The suspension is at full droop, and there is no shielding outside the cabin. The chain and the planetary will create noise that appears louder than what you would hear on the road. Many modern transfer cases, such as the NV140, 242, BW 4414, 4476, 4481, 4482 and 4484, use open planetary differentials to achieve a torque split between the rear and front axles. These units will be hellaciously noisy on the lift but quiet on the road. If you are ignorant of this fact you will be wasting a great amount of time.

Whining from the transfer case

Transfer cases do not use hypoid-type gearing. In 2 High for 4W high, power flow is straight though from the input to the mainshaft to the driveshafts. Bearings do not whine; they growl. Whining noises will usually be a product of something wrong in one or doth differentials. Driveshafts act to transmit many differential noises into the transfer case or transmission so that the sound appears right under the driver’s seat. Take extra time to carefully sound out where the problem is coming from, as many a transfer case has been sold only to find out the problem is still there in one of the differentials.

Transfer-case rear-bushing failures

Rear-bushing failures are caused primarily by lack of lubricant or problems with the rear yoke, driveshaft, U-joints, or a driveshaft being too short or out of balance. A driveshaft that is extremely rusty or covered with undercoating can be way out of balance. The average driveshaft shop can spin-balance a shaft to only about 1,800 rpm, which is way out of touch with modern reality. Some racing-driveshaft builders have invested in equipment that can spin a shaft up to 12,000 rpm to ensure a perfect rotating balance throughout the engine’s power band.

Shaft vibrations usually are associated with balance or rear-yoke issues. Numerous TSBs describing these problems are available, and you need to review what is available for the year, make and model you are working on. GM issued one such tech bulletin, #01-04-17-004B, that speaks to certain clunks, bumps and squawk associated with a rear driveshaft yoke.

Binding on turns

All 4WD vehicles will bind on turns when operated in 4WD High or Low on dry pavement. I will say it again: All 4WD vehicles will bind on turns when operated in 4WD High or Low on dry pavement. There are always going to be numerous complaints from shops and uneducated customers as to binding on turns in 4WD. The answer is simple: 4WD high or low is a 50/50 torque split front and rear. This is to be used only off road, in snow, sand, dirt, grass etc. If the tires cannot slip, you will get binding, lockups and a big bang as the components release the torque load created in turns and the inboard wheels are traveling less distance than the outboard wheels. This leads to early chain failure, overheated fluid and other parts failures.

We see early chain failures on Jeeps with the 231 transfer case all the time. It is either lack of lube or – if the chain had a brown, baked-on film – overheating because the customer is driving on the highway in 4WD (usually in the rain) looking for better traction. This is not what the unit was designed for. The 271 and 273 units found in Ford trucks also suffer early chain failures because they use very large chains and low-lube conditions lead to overheating and chain failure very quickly.

Lubrication schedules

Protect your customer and your warranty by getting your transfer-case customers into the habit of replacing the fluid once a year or every 12,000-15,000 miles. The customer is never going under the vehicle to check the fluid. If there is a leak it usually is too late to save the unit when he notices it. You can make some extra money on service and keep the customer on the road for a win-win situation. A great many of the late-model active transfer cases and all-wheel-drive transfer cases generate a bunch of heat at highway speeds and are hard on the oil, requiring more-frequent changes.

Tire-related failures

The importance of correctly matched tires (size and pressures) cannot be overstated. Most complaints and failures of active and AWD transfer cases begin with tires that are not within 1/4 inch in circumference. Recently we had a heated conversation with a shop that was working on a vehicle that had four new tires on it and still had the same problems. When we asked them whether they had measured the new tires, they replied: “What for? They are new.”

When they finally measured the NEW tires, the rear two were an inch different from the fronts, and they were brand new. The shop owner could not believe it, and I said, “I guess you were never involved in racing.”

He asked what that had to do with it, and I explained that when a race team inflates 40 sets of tires for the weekend, they use a stagger gauge (figures 1 and 2) to measure them and get equally matched sets. Sometimes you want the right-side tires to be taller than the lefts for oval racing to get the car to turn in better; in road racing you want them to match.

We sell a stagger gauge, which is just a big caliper that measures tire circumference in direct reading, for about $50. Guys who want to set the car up on a lift and measure tires around the center of the tread with a tape measure are losing that much in labor when it could be done on the ground in five minutes by one man with a stagger gauge.

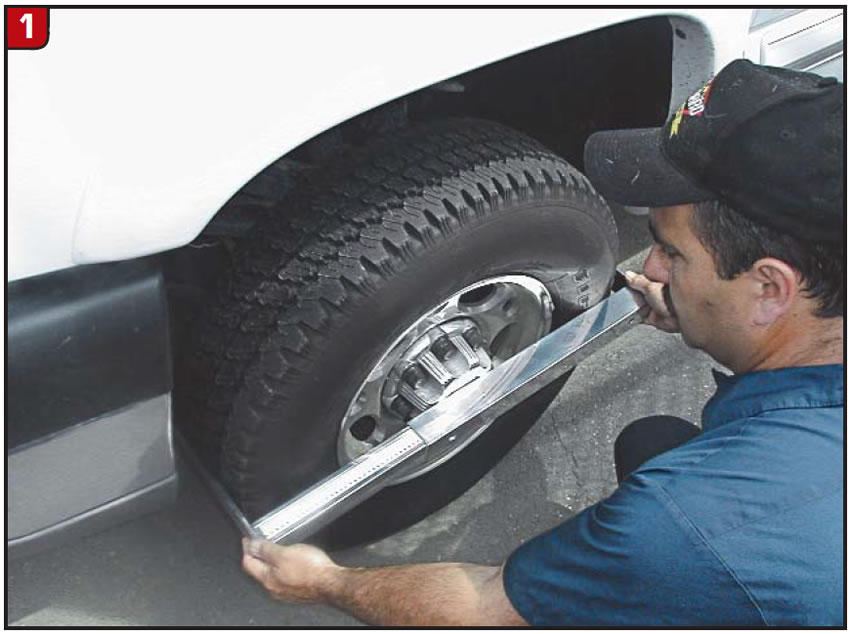

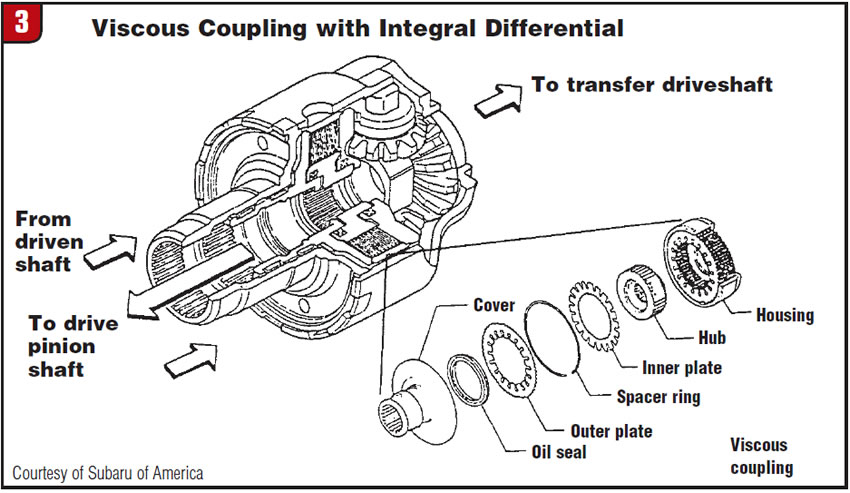

Active transfer cases, AWD transfer cases, viscous-coupling transfer cases (Figure 3) and differentials all suffer badly with mismatched tire sizes. The unit sees the difference in wheel speed as a slip and tries to compensate for it by activating the viscous or the clutch pack. This immediately overworks those components because the tire-size difference will have them working all the time. You can overheat a viscous coupling in 50 miles, because it was designed to send power to equalize the shaft speeds and then relax and wait for the next slip. Off-sized tires create an endless slip condition, and pop goes the weasel.

Remember that sidewall labels mean nothing; only a precise measurement is enough, and even new tires all from the same mold grow to different sizes when you inflate them.

Updates and improvements

You should always inquire from your supplier about any new parts, improvements or updates available for the unit you are working on. This whole industry is based on the concept of improving on original designs and creating a finished product superior to the original. Just throwing parts at a problem does not overcome the flaws that were originally designed into the unit. Ask whether there are any updates for what you are working on.

For instance, 246, 261 and 263 transfer cases all fail badly because of the OEM magnesium case, in which the oil pump beats through the case, and because magnesium does not like steel you get wear in the bearing bores because of the dissimilar metals. We designed an aluminum heavy-duty replacement rear-case half that is made in the USA (creating jobs at home) and is much stronger than the original and the Chinese copies now available. Ask and ye shall receive.

Understanding what you are working on

Success is predicated on good information. Many people, for whatever reason, are groping around in the dark. Ignorance is very expensive. When you come across a unit that is either a first-time experience or something you don’t see often enough to be comfortable with, go to the manual. Reading up on how it works and the theory of operation and power flow will do wonders for your diagnostic abilities and get you on the right page for assembly tips and parts location. There are endless suppliers of factory-approved manuals like Mitchell OnDemand as well as subscription services from the OEM manufacturers that will have you ahead of the curve.

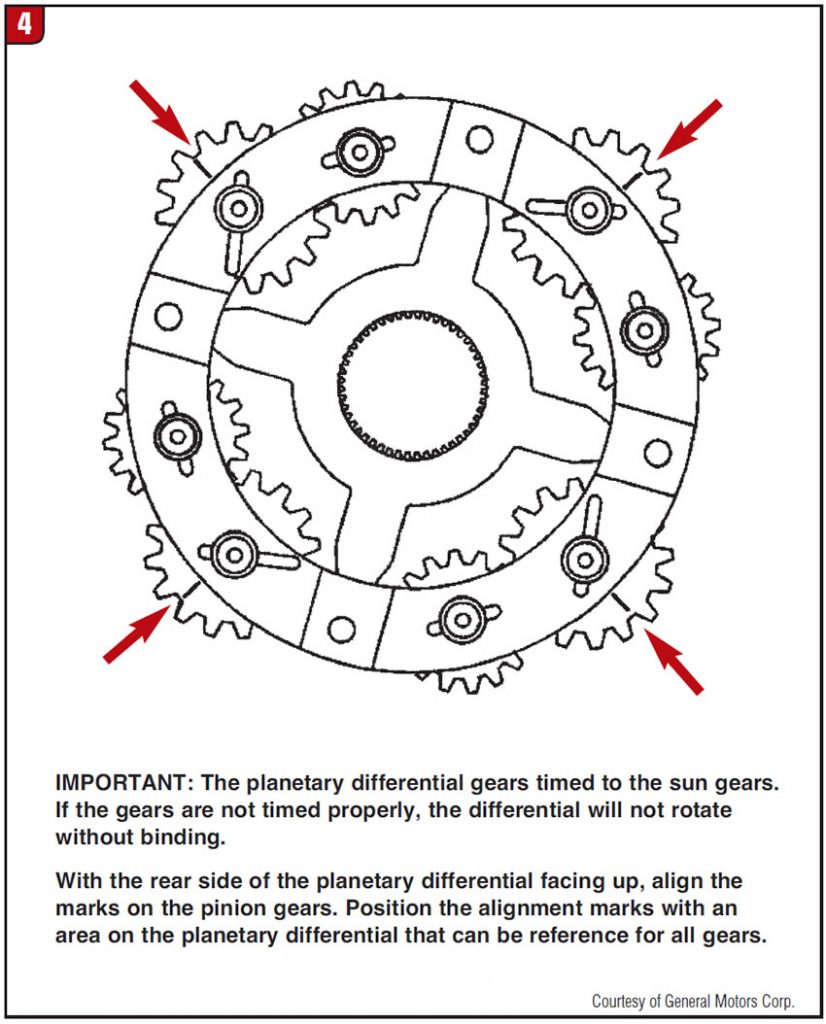

For example, in the BorgWarner 4481, 4482 and 4484 transfer cases, you will find a planetary-type differential with two sun gears. We get an unbelievable number of phone calls from people who have taken these apart and cannot reassemble them. You won’t figure it out without the book. The pinion gears for each sun gear are marked and need to be clocked correctly to put the sun gears in. Figure 4 shows the proper positioning. Chance favors the prepared mind. It is your investment in yourself to be well informed, as information is always the most-valuable commodity. Good information and education is the only way to success and profits in what has become a very sophisticated industry.

IMPORTANT: The planetary differential gears timed to the sun gears. If the gears are not timed properly, the differential will not rotate without binding.

With the rear side of the planetary differential facing up, align the marks on the pinion gears. Position the alignment marks with an area on the planetary differential that can be reference for all gears.