Technically Speaking

- Author: Wayne Colonna, Technical Editor

- Subject Matter: BYKA

- Issue: Erratic shifts

Tom from “Transmission Shop” in Minnesota had a customer come in with a 2012 Honda Odyssey with a six-speed BYKA transmission experiencing erratic shifts. It had an intermittent and inconsistent 2-3 shift where sometimes it would have a slight flair and bump while other times it would experience a large flair and a bump. Other times it shifted into 3rd then neutral and back into 3rd.

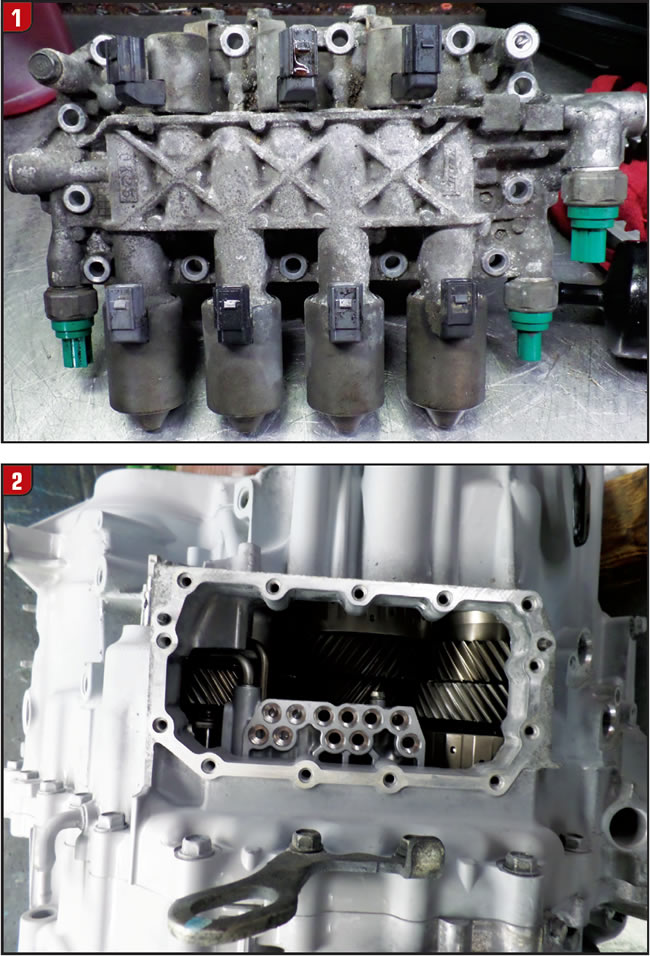

A dealer had previously diagnosed this vehicle pulling a P0776 code for Clutch Pressure Control Solenoid Valve B Stuck off. They recommended he replace the solenoid assembly (Figure 1). The price to do this work must have been exorbitant as the vehicle owner brought it to Transmission Shop for them to do the repair, and they did.

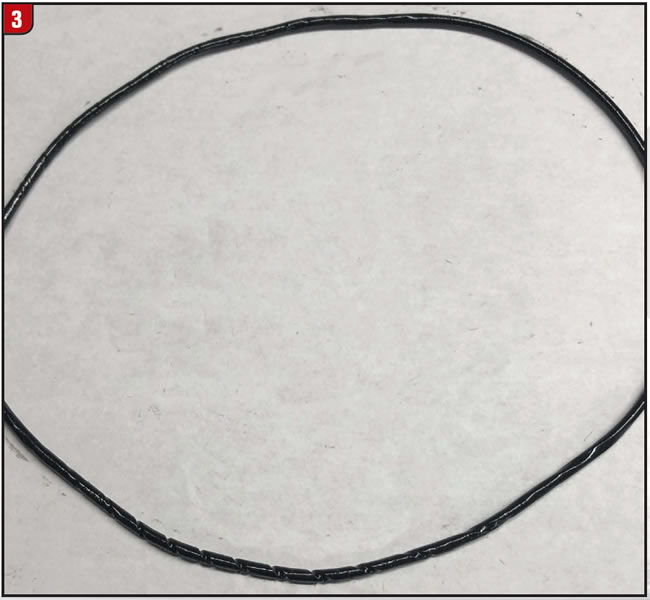

A road test confirmed that the problem was not resolved by replacing the solenoid assembly. The solenoid assembly was removed from the transmission (Figure 2) so air checks could be made. This discovered a leak in the 3rd clutch drum. When the piston was removed for inspection, something quite unusual was revealed. The outer o-ring seal in the 3rd clutch drum was twisted, producing spiral gaps in the seal as seen by the photos Tom sent in: figures 3, 4 and 5.

This type of failure is typically seen on long stroke hydraulic piston seals when some segments of the O-ring slide while other segments simultaneously roll. This can happen with eccentric components, wide clearance combined with side loads, uneven surface finishes, inadequate lubrication, o-ring material is too soft or stroke speeds are too slow. The twist here is that there were no visible signs seen that would point to the cause. A new o-ring was installed and down the road it went. If it returns with the same condition, it may be pointing to a drum flexing slightly out of round while under load. The problem was quite odd-eye-see!

Many thanks to Max Dease for figures 1 and 2; having one of these on his bench.