Up To Standards

- Subject: Design and operation of Magna Powertrain transfer cases

- Units: MP1222, 1225, 1226, 1625, 1626

- Vehicle Applications: GM trucks and SUVs

- Essential Reading: Rebuilder, Diagnostician

- Author: Mike Weinberg, Rockland Standard Gear, Contributing Editor

In the ever-changing world of automotive technology, we must keep up with an endless supply of new car models and their components. We will look at a new family of transfer cases manufactured by Magna Powertrain.

This name may be new to you, but a look at the company’s history will reveal a number of familiar brands under one company. The company started life in 1957 as Multimatic, founded by an Austrian entrepreneur, Frank Stronach. The company merged with Magna Electronics in 1969, becoming Magna International, a global supplier of automotive systems, components and complete modules to the auto manufacturers. Magna Powertrain is a division of that conglomerate.

The New Process Gear division of Chrysler Corp. formed a joint venture with the Muncie Gear division of GM to form New Venture Gear, which manufactured transmissions, transfer cases and components. This joint venture was acquired by Magna International and renamed Magna Powertrain. Magna has become one of the largest Tier 1 suppliers to the world’s automakers, with factories and engineering centers all over the globe.

We are all familiar with the old New Process/New Venture numbers designating transfer-case models, such as 231, 246, 249 etc. These numbers have a purpose in describing the number of speeds, torque-transfer method and torque rating of the individual unit. In an article some years ago I provided the keys to the three-digit numbers. Magna Powertrain has gone to a four-digit model designation. The new transfer cases we will be looking at here are the MP1222, 1225, 1226, 1625, 1626, 3023 and 3024 models found in the GM light-duty-truck line. We will decode these numbers below, and you will see that understanding the numbering system can be a great help in identifying what you are working on and in some basic diagnosis.

In the numbering code the first two digits indicate the type of torque-transfer mechanism used in the transfer case:

- 11 – Part-time transfer case without synchronization, used in vehicles with live front axles with no disconnect

- 12 – Part-time transfer case with synchronization

- 15 – Part-time, electric shift, without synchronization

- 16 – Part-time, electric shift with synchronization

- 20 – All-wheel drive with a center differential with no locking mechanism, 50/50 or 40/60 torque split front to rear axle, no driver control

- 22 – Center differential with locking mechanism; driver controlled

- 23 – Transfer case equipped with Torsen differential (gear-drive differential); used in Trailblazer SS models

- 24 – Transfer case equipped with a hydraulic-pump coupler similar to NVG 247 models.

- 25 – Transfer case equipped with a viscous coupling and no differential

- 30 – Transfer case that is “active” with computer control, electronically shifted, clutch driven.

- The third digit is the number of speeds:

- 1 – one speed

- 2 – two speeds

- The fourth digit indicates the torque capacity of the unit. There are at present eight levels of torque, with zero being the lowest and 8 being the highest (Ford Super Duty 750 series etc.)

- Here’s a breakdown of the torque rating represented by the fourth digit:

- 2 – 800-1,000 Nm

- 3 – 1,000-1,200 Nm

- 4 – 1,200-1,400 Nm

- 5 – 1,400-1,600 Nm

- 6 – 1,600-1,800Nm

The new units we will be looking at here are:

- MP 1222, 1225 and 1226, which are GM RPO codes NQG. These part-time transfer cases have mechanical shift with synchronizer and two speeds. All NQG models are in this class of product with three variations of torque capacity.

- MP 1625 and 1626, which are GM RPO codes NQF. These part-time units have electronic shift with synchronizer and two speeds. All NQF models are in this class of product with two variations of torque capacity.

- MP 3023 and 3024, which are GM RPO codes NQH. These are active, electronic, computer-controlled, clutch-driven two-speed units. All NQH models are in this class of product with two variations of torque capacity.

In this article we will have a look at the MP 1200 and 1600 series. In next month’s article we will go over the MP 3000 series, and the following month we will cover the electronics, trouble codes and diagnostics of the 3000 series, which is a book by itself.

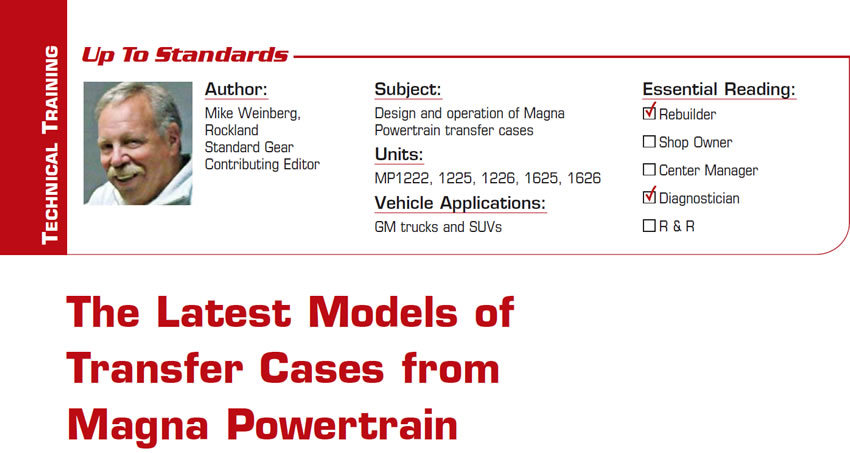

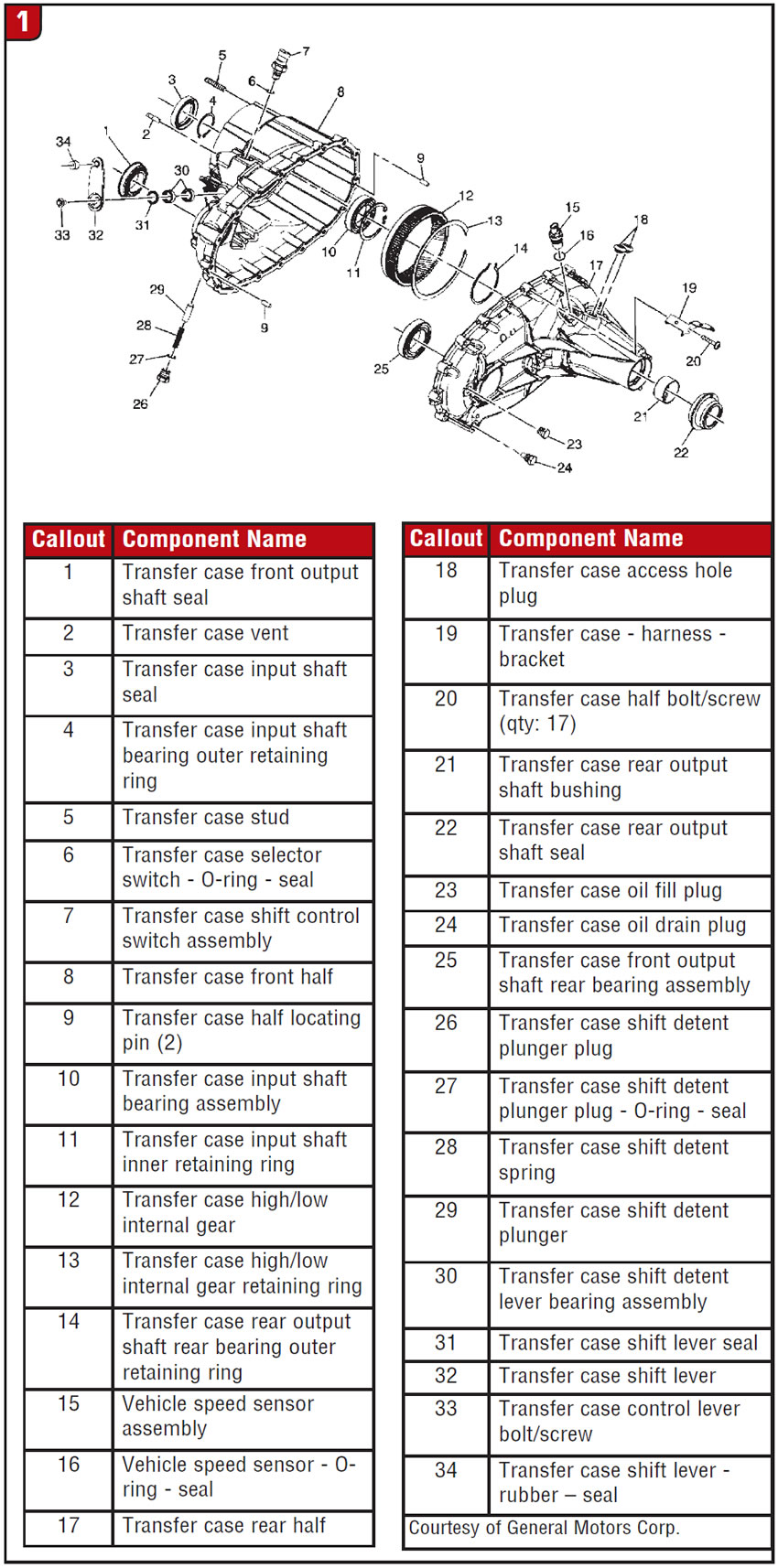

The MP 1222, 1225 and 1226 series are simple, part-time, two-speed units mechanically shifted with a synchronizer, as we can tell from the number designation. The units are found in GM trucks behind the 4.3-, 4.8-, 5.3-, 6.0-, 6.2- and 6.6-liter engines, which is why there are three levels of torque capacity in the three models. Looking at the exploded parts diagrams in figures 1 and 2, we see a planetary for low reduction and two shift forks, one shifting the synchronizer, which has three-piece rings for improved shifts into four-wheel drive, and the other fork shifting the range hub into the input or the planetary at the driver’s command. There is an oil pump driven off the mainshaft to provide pressurized lube throughout the unit. A reluctor driven by the output shaft feeds information on vehicle speed to the speed sensor mounted on the rear case half.

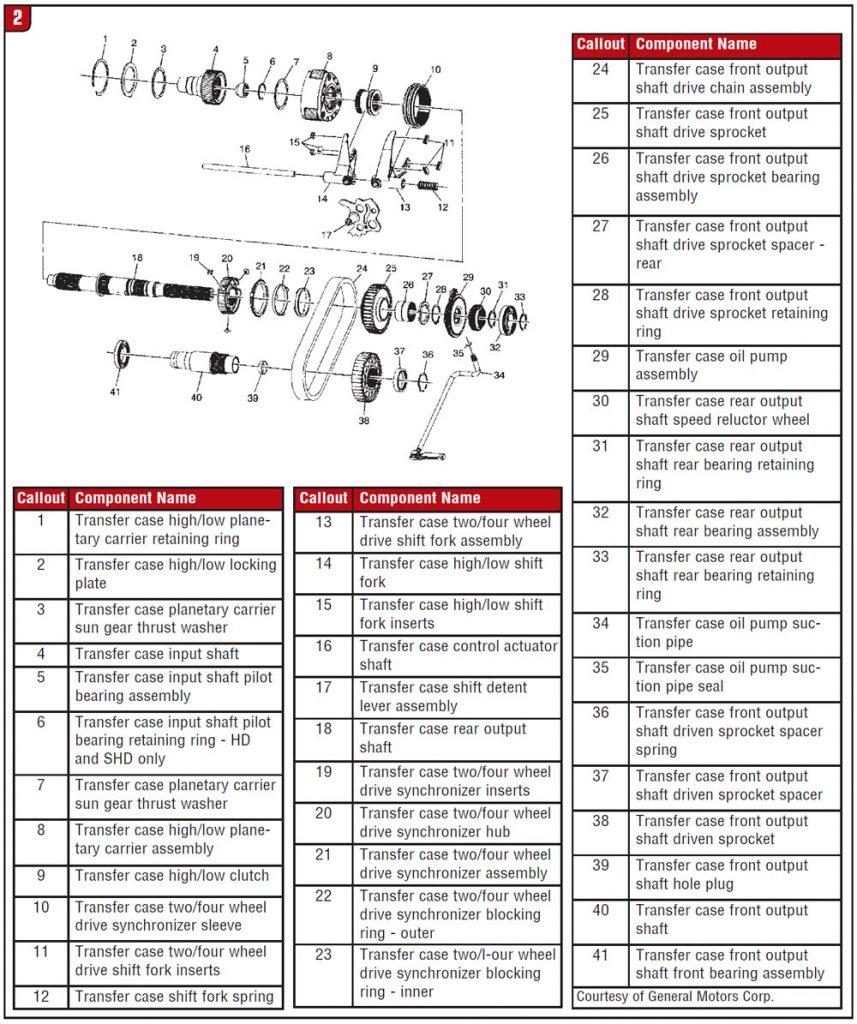

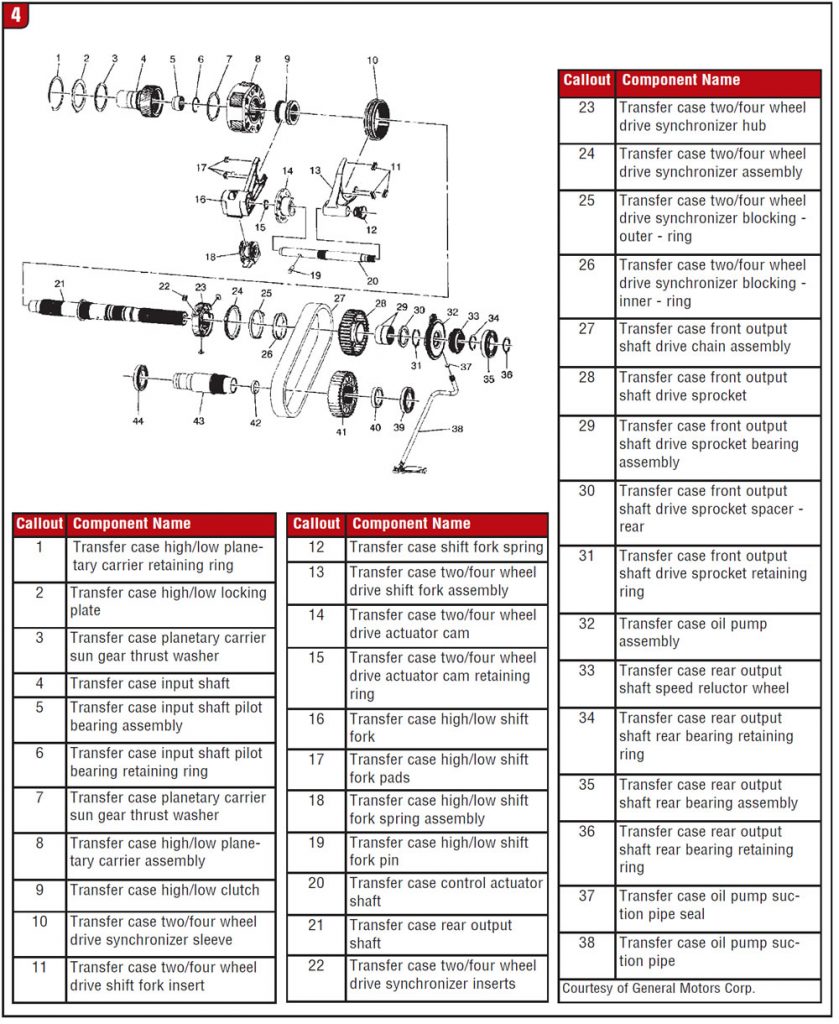

The MP 1625 and 1626 are heavier-duty electronically shifted units with two speeds and synchronization. Looking at the exploded views in figures 3 and 4 you can see that there are two shift forks, with a rotating cam on the shift shaft to provide detent and actuation of the forks by the electric shift motor. The electric motor/encoder does not have a brake in it like that in the NVG 246 and is not serviceable. There is a heavier-duty five-pinion planetary for low reduction. These units are shifted by an electric-dial type of switch on the instrument panel. There are four positions the driver can command: 2WD, 4WD high, 4WD Low and Neutral. The MP 1625 is found behind the MYD 6L90 automatic transmission, and the MP 1626 is found behind the MYD 6L90 trans and the MW & Allison transmissions.

The driver may command a shift into any of the ranges at any time; however, a shift into 4WD Low range cannot be achieved until the vehicle meets certain parameters: The ignition switch must be in Run, the automatic transmission in Park or Neutral and the vehicle speed below 3 mph. These units are capable of setting at least 12 DTCs, and you will need a service manual to provide the necessary diagnostic routines and tests. I have found Mitchell OnDemand to be an excellent program with really good wiring diagrams and information. We have come to the point where there are 50 pages of teardown and assembly and 130 pages of electrical diagnostics. Unless you have access to the factory manuals online, get hooked up with Mitchell and consider the cost as the purchase of the most-useful tool in your box.

Next month we look at the MP 3023 and 3024 series, with a partial look at the electronics. In April we will cover the basics of diagnosis of the electronic shift, clutch application and trouble codes.