Roger Roberson worked his whole life with his hands. When he was young he would do work on small engines, lawn mowers and motorcycles and the like. But one day his car, a 1977 T-Bird, needed to have its transmission rebuilt.

Naturally he took it to someone he knew- Corbet Bonds, then-owner of Delta Transmission. Delta Transmission was first covered by Transmission Digest in 2000 (Vol. 19, No. 6). It is just as clear now as it was then that Roger’s fascination is what led him to his position. Unlike some customers, Roger didn’t sit in the lobby drinking coffee, or run errands while his vehicle was repaired. Instead, he watched the process of the transmission being rebuilt. “I thought, well, shoot that’s kind of neat,” he said.

Roger found the process interesting, and at the time he was working a job that he hated. So he talked to his friend Corbet and asked for a job.

Corbet hired him on the spot and “the rest is history,” Roger said.

“Later on I got the chance to buy in as a partner, and eventually he (Corbet) retired, and I bought him out.”

He and his manager, Tim Welsh, had always been technically minded, Tim said.

Tim Welsh originally worked elsewhere, but has now been working for Delta for 22 years, he said. “I ended up interviewing with Roger and he hired me and I’ve been here for 22 years,” Tim said.

Tim always tries to “strive for excellence,” he said.

“He’s been with me for about 22 years. When I hired him he was living in Little Rock. Of course I’m about 10 years older than Tim but he’s done a lot for the business.”

“We feel like family,” Tim affirmed.

Roger said that he has had customers drive from as far as 100-120 miles in order to get work done in Delta. This is largely because Arkansas has a large portion of its population living in spread out rural areas. They don’t call it “the Natural State” because of all the cities, after all. “We get out all over Arkansas; and some of these smaller towns that don’t have any tranny shops see us online and they’ll come.” He does work for people all over the state. Roger doesn’t only do work for the average Joe, but also does work for fleets and dealerships in his area.

“Last year we had the best year we’d ever had in the history of Delta, and could have had an even better year but you can’t find any help, that’s you know, qualified.”

He strives to keep up with increasing technology and the changing landscape of vehicles while also maintaining a consistently positive relationship with the customers.

His golden rule is to treat people the way he would like to be treated.

One of the big issues he has faced over the years is getting help, because of the rural nature of Arkansas. Even Conway, which is one of the bigger cities in the area, is fairly small in comparison to Little Rock, a short drive south. Many technicians tend to gravitate to where there is more work.

“Last year we had the best year we’d ever had in the history of Delta, and could have had an even better year but you can’t find any help, that’s you know, qualified.” Despite having a successful shop, his workforce isn’t particularly large. “Right now we’re at 9 employees all together.” That’s including himself and Tim. They have “three builders, three r&r men and a general tech,” Tim said.

“That’s just always been my problem. You know, other than that..” Tim said on hiring help.

A symptom of rural living generally tends to be longer commutes to work, and the automotive repair industry is no exception. Roger stated that one of his employees drives all the way from Marshall every day for work. That’s about around a 68-mile drive to Conway, which takes roughly an hour and 25 minutes. “And I’ve got some other boys that’s driving like 25 miles one way.”

Roger also said there is sometimes trouble with younger technicians he has seen in the past. Though he said he didn’t have this problem with his own employees, he said young technicians often don’t want to get their hands dirty the way that they sometimes need to in order to do a repair properly.

“You can’t even find somebody to train anymore.”

Roger admitted that he didn’t keep up with the exact number of transmission jobs they do per week, he said that the low average was around 15.

Roger is 60 years old, and plans, if all things go well, to retire at the age of 62. He is hoping that Tim will take over the business following him, being that he has no family in the business. But according to both him and Tim, they might as well be family with how long they’ve known each other.

Like many transmission shops, Delta does general repair work in addition to transmission-specific work, but Roger said he tries hard not to steal customers from any other facility, and if he thinks the work requires another shop or the customer’s regular general repair shop, he will be quick to recommend they take their car there. Roger is also dedicated to only selling necessary repairs. “We’re not going to sell the customer anything they don’t need. We’re gonna take care of them,” he said.

Roger thought about whether he had any unique or surprising jobs in the shop recently, but he said after so many years, nothing surprises him anymore.

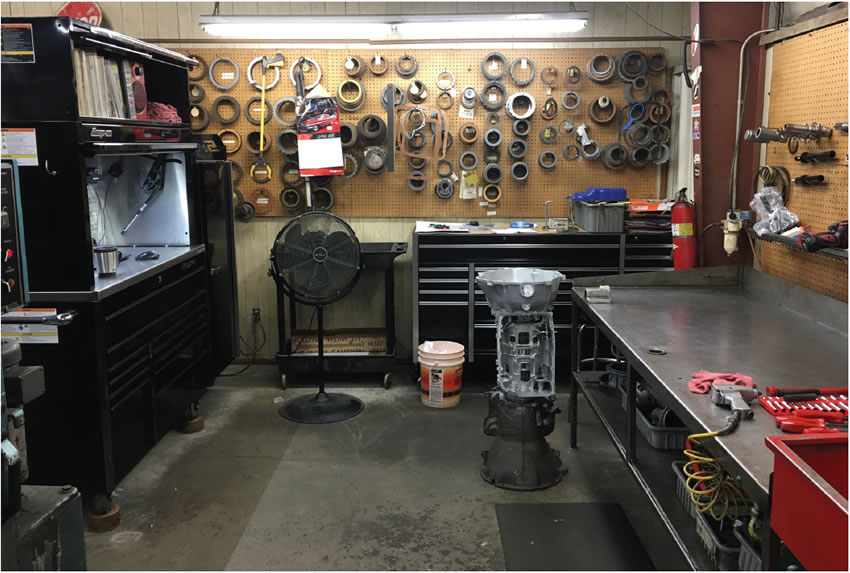

Roger said when they first started the shop had simple, basic jack, but now has lifts and in their biggest lift they can raise up an RV. They can fit “up to a 35-foot motorhome on our largest drive on rack,” Tim said.

In 1992 they were at 5,000 square feet of space and now they’re at 10,000. “We’ve added on to the shop twice,” Roger said. But perhaps more importantly, “We started out with a fan and now half our shop is air conditioned now.” Delta currently operates 11 bays.

“We use the internet quite a bit for our flow charts and diagnostics,” Tim said. He said that technology advancement was the biggest change he had seen in the industry. “Technology is a lot crazier.” In order to keep up, he said there was “a lot of reading” involved. Tim said utilizing modern technology like the internet is a big help on a lot of repairs.

Tim also said they have increased business since early on and they try to stay up-to-date with technology and the automotive repair world by attending events and seminars.

Tim said that, managerially, he stresses the importance of fixing something right the first time and making sure a customer doesn’t have to come in because something wasn’t repaired properly.

One thing he’d like everyone to know is that, “We’re an honest business,” Roger said. In fact, his dad gave him some advice that Roger lives by: “When I first started in business me and my dad were travelling down the road and he said ‘son, if you treat your customers the way you want to be treated, then you’ll be all right.’”