Up To Standards

- Author: Mike Weinberg, Contributing Editor

It is 6 p.m. Tuesday, Oct. 28, and I am about an hour away from Daytona Beach, Fla., where I will compete in the final race of this season. The sanctioning body is the Grand American Road Racing Association, the road-racing division of NASCAR. This series, on premier race tracks in the United States and Canada, features 10-12 races per season, all televised on the Fox Speed Channel.

This is endurance racing, with the shortest race being three hours and the longest the 24 Hours of Daytona. The rules require that two men drive the car in a three-hour race and three or four men in the 24-hour race. These races are the ultimate test of men and machines because of their length and the fact that in the class I drive in, originally stock vehicles are modified to higher performance and safety standards, but the chassis is not a tube frame but remains essentially stock.

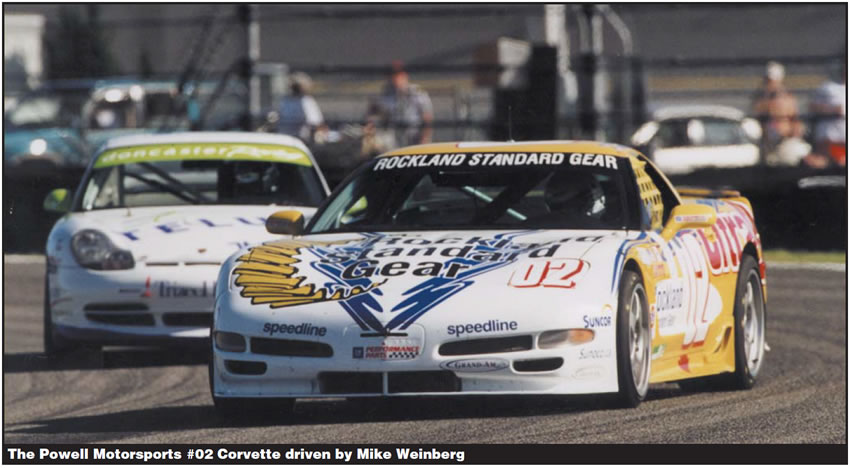

The team I drive for, Powell Motorsports, runs two cars in the GrandAm Cup series, both 2003 Chevrolet Corvette Z06s. I have driven for this team for the past three years, and the team has won four championships and been runner-up twice in the past six years. As we near Daytona I am studying my position in the championship standings. I was 7th overall out of 116 drivers in the points going into the Sept. 23 race at Mosport Canada.

During the second practice session my co-driver backed the #02 Corvette into the turn 4 wall at about 120 mph. These cars are extremely well built and he walked away without a scratch, but the car was a write-off. John Powell, the team owner, borrowed the car that I drove last year from its present owner, and I qualified that car 5th on the grid, and we finished 7th in the race.

Shortly after the race I was notified that the team had let my co-driver go. In professional racing, the easiest part to replace on a race car is the driver and the hardest to replace is a sponsor. It is OK to crash in the race if you are moving to the front, but crashing in practice is generally unacceptable unless something broke in the car.

The following week we had a race in Mont Tremblant, Canada, but I would not be driving, as the #02 Corvette would not be ready in time. The #11 Corvette finished 3rd in that race, and since I did not drive, my points standing would begin to slip.

On Oct. 4, we were in Alton, Va., at Virginia International Raceway with a brand-new #02 Corvette. I spent the first practice day getting the handling dialed in on this new chassis, changing spring rates, making shock adjustments, and working with new combinations of sway bars and tire pressures. By the afternoon session we had the chassis dialed in but lost an engine. The reluctor wheel on the crankshaft that sends the crank-position signal to the computer somehow spun and we failed the engine. The crew installed a spare race engine, but during the Friday session the engine was “soft” and we never got it to perform to the usual power.

During the race on Saturday, on the 160-mph back straightaway the engine let go with a bang that took the front wheels off the ground, so I shut everything down, coasted into the pits and watched everyone else have fun, while I and the team finished out of the points.

These LS6 racing engines cost $28,000 each, and clearly there was a serious problem going on with the engine builder in Detroit, as we hadn’t lost an engine in the previous two seasons. The engines start out as a stock LS6 (Z06) Corvette motor and are equipped with a racing cam and head package, dry-sump lubrication system, and a remapped ECM, and they make a dyno-tested 525 hp at the rear wheels. The Corvette is then equipped with an Exedy Hyper Single Plate performance clutch, and a close-ratio T56 six-speed. Working with both GM Racing and Tremec Corp., which designs and manufactures the T56 transmission, early in the season we developed a close-ratio gearbox. The T56 in the Corvette comes in two stock ratios, one for the LS1 engine and one for the LS6 (Z06) engine.

- LS1 ratios: 2.66, 1.78, 1.30, 1.00, 0.74, 0.50

- LS6 ratios: 2.97, 2.07, 1.43, 1.00, 0.84, 0.56

- Close-ratio race T56: 2.29, 1.61, 1.22, 1.00, 0.85, 0.75

The stock ratios are excellent for street driving, but on a road course the stock ratios lose too much engine speed on shifts. We shift these cars at 6,800 rpm, and the stock ratios were costing us 1,500 rpm per shift. With the close-ratio gearbox, you lose 750 rpm per shift, and when you are shifting up and down a dozen times each lap, it makes a considerable difference in lap times.

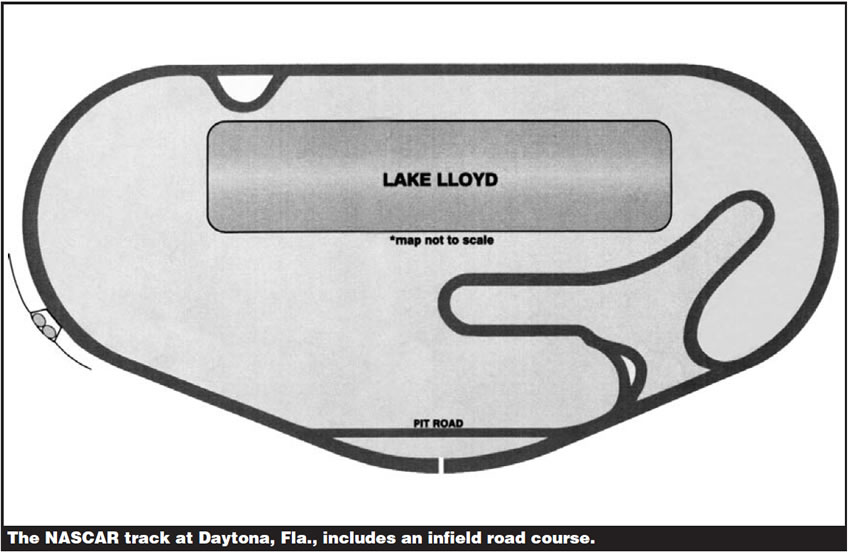

Wednesday morning we are on the track for the first practice session. Daytona is a “super speedway” tri-oval race track. We are using the 24 Hours course, which is 3.56 miles long and incorporates the three oval turns and an infield road course. The oval corners are banked at 32°, which is steep enough to be very difficult to walk up, and are incredibly fast. We reach speeds on the oval of about 191 mph, but the infield turns are not banked and require more finesse to get through quickly.

I take two laps to get some heat in the engine and warm up the tires and brakes, and then I begin to push harder. This engine also feels “soft,” and as the crew chief calls off my lap times, it is obvious we are down on power. I bring the car into the pits, and the crew goes over the engine looking for an answer. Everything checks out and I put my new co-driver, Don Knowles, into the car for some track time, and he can’t get any more out of the engine.

The crew now begins an in-depth analysis, and after verifying every possible component we are still at square one. I put the car back on the track in the third practice session, and after four laps the oil pressure begins to fluctuate. I tell the crew chief, who asks me to take one more lap and see whether it stabilizes.

Exiting the second hairpin on the infield, I see a big cloud of white smoke from the exhaust, and the engine begins to miss badly. I call the crew chief and tell him I believe the engine has swallowed a valve, and I turn onto the banking and stay on the bottom apron in case we are losing oil and slowly work my way back to our pit box.

The crew pulls the valve covers, and the right bank has a collapsed valve spring. Since this is an interference-type engine, the piston is probably damaged and maybe the cylinder bore also. A third engine is now toasted, and there is a major conference between John Powell, the crew chief and the engine builder by cell phone. The engine builder decides to charter a plane to bring a fresh new engine to the track early Friday morning, and the crew begins to remove this engine from the #02 Corvette.

At 5:30 a.m. Friday the crew receives the new engine and begins to install it. We have a 15-minute qualifying session at 11:30 a.m., and the race will begin at 5:30 p.m. under the lights. At 11 a.m. I am belted in the car while the crew adds the last fluids and makes sure everything is correct. I start this engine for the first time and it has a real snap to it, and my experience tells me that this is a good one.

There is, however, no power steering, and the crew checks the fluid. We suspect that the pump is air bound, and I set off from the paddock to the track weaving side to side to get the air out. As we get the green flag and the qualifying session begins, the power-steering pump seizes and rips the belts off the engine, and I shut it down again. I pull the car off to the inside of the track and get towed back to the paddock.

At this point I am looking for the black cloud that must be following me around, and I have to start at the back of the field because we got no lap times in for the qualifying session. While the crew replaces the power-steering pump, Don and I go get some lunch to build up our energy reserves for the race. We will be starting 50th in a 56-car field, and will have a tough night’s work ahead of us.

At 5:20 p.m. I am in the car on the grid, going over the last-minute checklist. The radio volume is tested, the pump that puts cold air into my helmet is working (the in-car temperatures during the race average about 145°F), my belts are tight and the window net is in place. We are on full tanks, and I adjust the brake bias to the rear to compensate for 192 pounds of 110-octane racing fuel. When we have enough heat in the engine, I cut the power and wait for the national anthem and the command that follows: “Gentlemen, start your engines.”

The pace car takes us out on the track for one pace lap, and I weave the car back and forth to clean and heat the sticker tires and drag my foot on the brake to get the pads hot. We are now on the front straight, and I get set for the start. This series uses a NASCAR flying start, which means you can’t improve your position before you pass the flag stand. From the 25th row the starter looks about ¼ mile away. I see the starter wave the green and the leaders take off, while in my earplugs I hear “green, green, green.” I get on it, careful not to move up a position until I am by the starter stand. At that point there is nothing to do, because there are 50 cars funneling into the first turn, and I back off and stay out of trouble.

On the exit of the first turn, I am able to pick up a couple of positions and get a few more exiting the first hairpin. This is going to be a game of patience, and I have plenty of time to get through the traffic. Out on the banking I stay high and begin to get up to speed and pick up positions.

Coming off the oval onto the front straight, the car is flying. This engine is really strong, great fuel and oil pressure, and all the gauges are in the green. I pass a few more cars going into turn one. The #02 Corvette will run about an hour and 20 minutes on a fuel load if we have no full-course cautions, and I concentrate on being easy on the car and steadily improving my position. We get lucky and catch a full-course caution about an hour and 22 minutes into the race, and my radio lights up with, “O2 pit now – driver change, fuel and tires.”

I acknowledge that I will pit this lap, and as I come off the banking toward the front straight, I drive down to the apron for the pit entrance, loosen and remove my belts, get the window net down and maintain my revs in 2nd gear to match the 45-mph pit-lane speed. I look for the “lollipop” sign that will guide me to the pit, shove the car into neutral, grab the cage and pull myself out of the car. Don gets in, and I help him get buckled up and plugged in while the crew changes four tires and fuels the car.

Forty-six seconds later Don leaves the pit, and we are in 6th place. He will take it to the finish an hour and a half from this point. I get my helmet and gear off, have a drink of water, and towel off the sweat. I am 8 pounds lighter, and the TV guys ask for an interview, so I get cleaned up a little to meet the press.

The crew chief and the team owner tell me I got the hard-charger award for the most-improved positions, and I start to pace the pits as Don engages in mortal combat with the Porsches. The #11 Powell Corvette is leading the race, Porsches occupy the 2nd and 3rd spots, and Don is in 4th working on the Porsches as the race comes down to the last 20 minutes.

Bad news – one of the Porsches has passed the 11 Corvette for the lead. Minutes later Don pulls off a great pass and is in third position, and I wish they would throw the checkered flag right now. With one lap to go, the field has stayed the same: The Porsche is leading and the two Powell Corvettes are in 2nd and 3rd, and next lap it is over. I help Don out of the car and give him a bottle of water, and we hustle over to victory lane with the two Powell team cars in the money, for podium pictures and trophies and checks and all the good stuff. After the press gets through with the interviews and the pictures, we dodge the champagne and have a shower and dinner.

In the scheme of things, we were pretty far down, but the engine builder stepped up with a good engine and we went from the back to the front with a car that was working perfectly. The engine builder is in pretty much the same business we are, and when something fell down in his process, he wound up eating three engines at $28,000 each and a $7,800 air-freight bill.

The three most-important qualities in a human relationship are honor, loyalty and persistence. Don’t let the comebacks and the daily grind make you lose your honor or loyalty, and being persistent in working to solve your problems and enhance the quality of your product will always be the key to success.