Up To Standards

- Author: Mike Weinberg, Contributing Editor

- Subject Matter: Dual clutch transmissions

- Issue: Mechanical theory

Second in a series

In last month’s article, we began to study the dual-clutch transmission, looking at its potential to eventually replace the common torque converter-planetary automatic transmission. In this chapter, we will look at the mechanical theory of operations on how these gear boxes work. We will be using illustrations from VW and Audi who were the first to mass market this design in 2003, in the Audi TT and VW Golf models.

BorgWarner designed and created the wet-clutch systems and the computer-controlled electronic modules that make the system work. BorgWarner’s brand name for these transmissions is Dual Tronic, while VW/Audi calls these transmissions DSG or Direct Shift Gear Box. We will be looking at the front-wheel-drive transaxle design here, but these units are available by different manufacturers in rear-wheel-drive and four-wheel-drive variations also.

The theory of operation of any design will transcend to any variation of that design, so understanding the basic operation will help to diagnose issues requiring repair. The dual-clutch transmission provides an improvement at present of 5% to 15% better fuel efficiency, quicker acceleration and reduced emissions. The BorgWarner Dual Tronic systems will be found in AUDI/VW, Bugatti Veyron, Nissan GT-R, Audi S Tronic 7 speed, the Mitsubishi Lancer Evolution X, Ford, Volvo, and BMW models, with more to come as other manufacturers move to these designs.

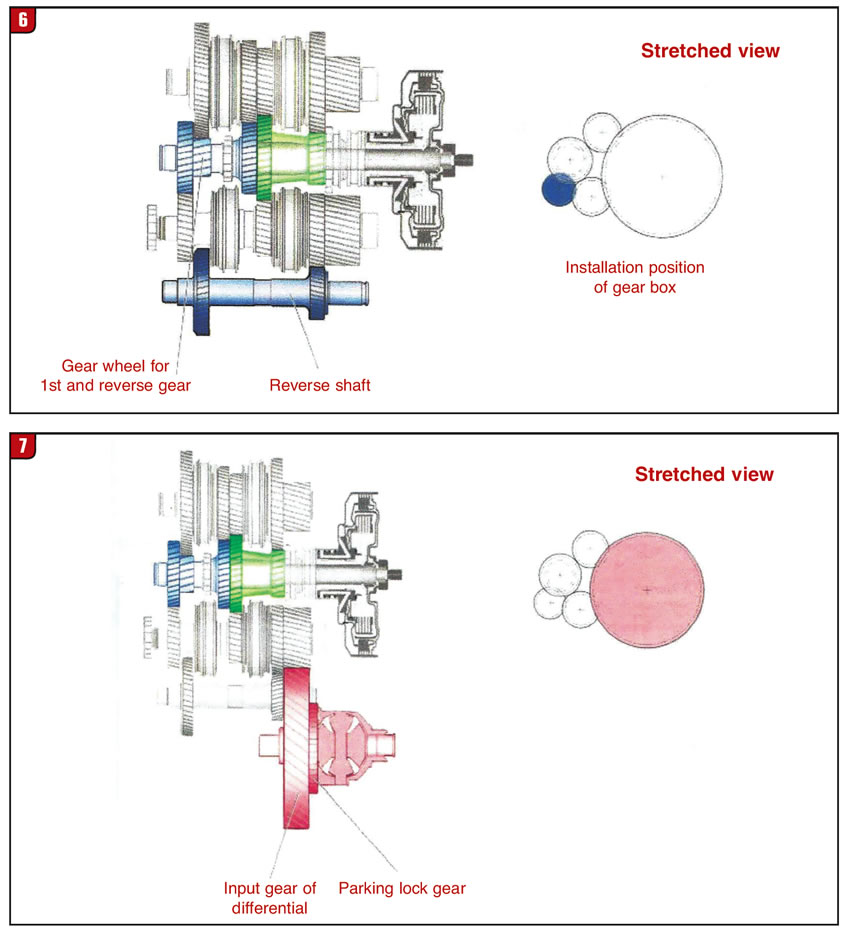

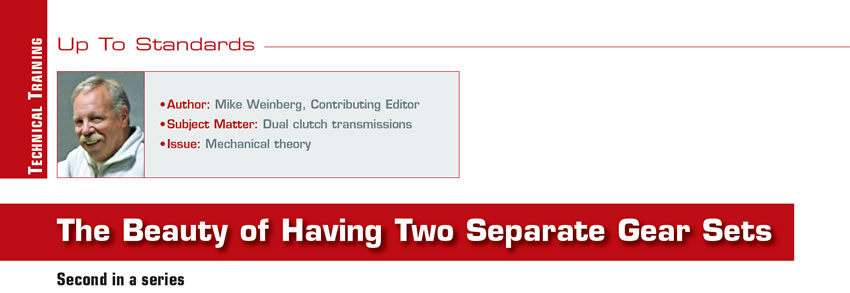

Perhaps the easiest way to look at a dual-clutch design is to realize that basically it is two separate transmissions combined in one unit operating independently. The gear train is basically a manual transmission and each of the transmissions have two multi-plate wet clutches. There are three input shafts that are housed within each other. The innermost shaft is a solid drive shaft that is splined into a dual-mass flywheel bolted to the engine crank shaft and to a crescent-type of oil pump to provide the hydraulic pressure to operate the dual-wet clutches, shift the synchronizers, and cool the transmission through an oil to radiator trans cooler.

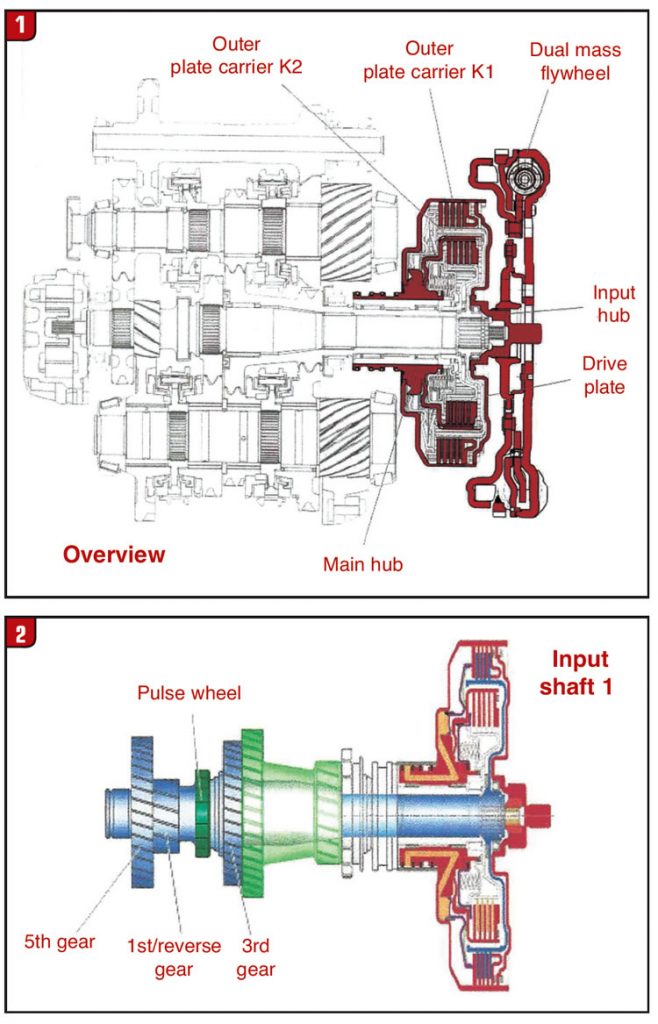

On the Audi/VW trans, the outer wet clutch is the K1 clutch and provides power to 1st, 3rd, 5th, and reverse gears. These wet clutches function exactly as a typical automatic clutch drum. The K2 clutch, which is the inner pack, powers 2nd, 4th, and 6th gears, as it splined to the middle input shaft. Both shafts have the gear sets mounted on them as well as a tone wheel that measures rpm so that the computer control can match the shaft speeds for very fast synchronization of the shifts. Keeping in mind that we are combining two separate transmissions within one housing, we now look at the output shafts of which there are two.

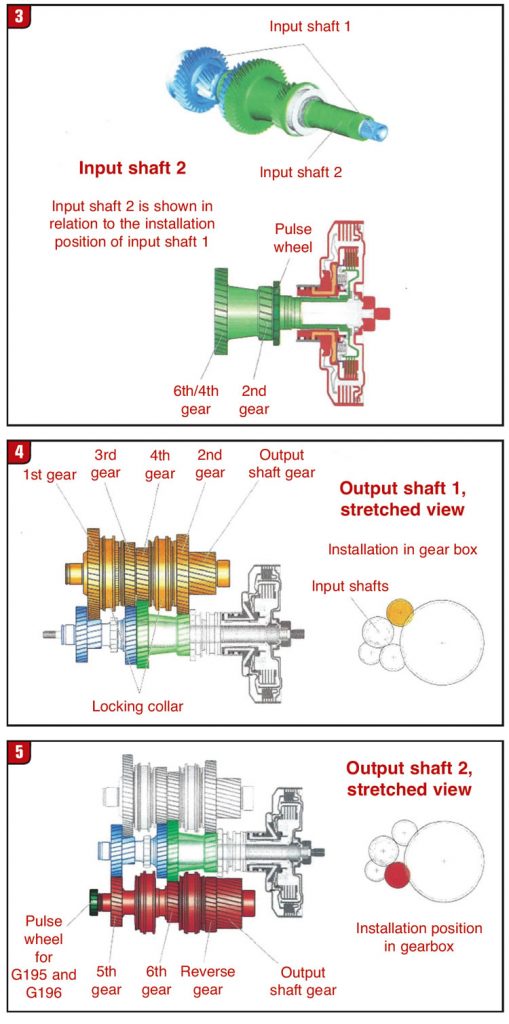

Output shaft 1 has 1st, 3rd, 4th, 2nd, and an output shaft gear to transfer torque to the final drive gear on the differential. Output shaft 2 contains 5th gear, 6th gear, reverse gear and an output shaft gear that sends torque to the final drive gear on the differential. Now we have to add one more shaft so that we can create a reverse rotation, so there is a reverse shaft, which meshes with 1st and reverse gears. Park mode is accomplished with a park-lock gear mounted on the differential carrier that operates with a typical parking-pawl setup to achieve a positive park position.

Synchronization on these units is achieved by using moly-coated rings in triple-, double-, and single-cone designs as is commonly found on most late-model manual transmissions today. The beauty of having two separate gear sets is that the transmission can preselect the next gear, which will not apply until one clutch pack releases and the other applies. This creates the lightning quick shifts possible with this design, without a major drop in rpm, and provides a transmission that will shift automatically through the computer-controlled module, or can be manually shifted through paddles or the stick, with no clutch pedal needed.

In our next chapter we will look at the mechanics and electronics that make these units shift.