Torque Converter Tech Tips

- Author: Ed Lee

Long-running debate concerning grooved friction material continues

The debate about whether to use a grooved or smooth friction lining to rebuild a converter originally equipped with a grooved lining has been going on since the day grooved linings first arrived at torque-converter shops. Those advocating a grooved replacement lining always seemed to have the upper hand because they used the very strong argument that “it is the same as OE.”

This argument has been losing ground lately because some of the clutches in OE remanufactured converters that originally had a grooved lining are now being remanufactured with a smooth lining. Torque-converter rebuilders even debate the reason why the OE manufacturers started using the grooved lining in the first place. Some say the grooved lining was used for shift feel, and others say it was used to reduce heat. These are probably the same people who inspired the light-beer commercial about whether people drink light beer because it is “less filling” or “tastes great.”

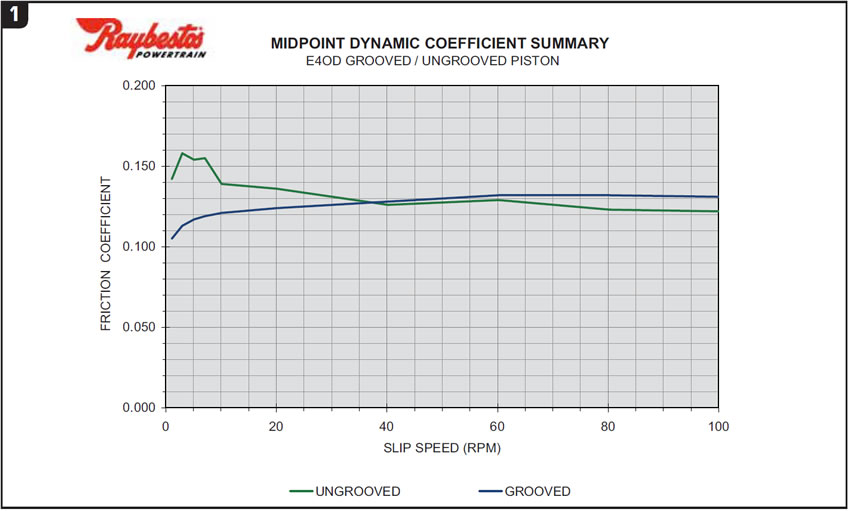

Raybestos Powertrain did some direct-comparison testing using clutches bonded with the same material. One grooved and one smooth (ungrooved) version of the same friction material were tested under the same conditions.

Figure 1 is a simplified version of the results of the tests done using an E4OD clutch with the tan friction material. Note that the smooth lining shows slightly more-erratic coefficient of friction at lower slip speeds (below 40 rpm). At slip speeds above 40 rpm, the grooved and smooth linings reacted the same. A higher coefficient of friction equates to an increased ability to hold or a reduced ability to slip. The high and erratic score of the smooth tan material at low speed indicates an increased potential to grab, stick or shudder. A smooth tan friction material should NEVER be used to replace what was originally a grooved tan material. A smooth friction material that contains carbon (Power Torque or high-carbon) will yield test results similar to the grooved tan material at slip speeds under 40 rpm.

In choosing a friction material for a replacement lining, a significant consideration should be the clutch-apply strategy that the transmission uses. If the clutch-apply strategy is EC3, either a carbon-weave or high-carbon lining is the wisest choice. For any modulated apply strategy except EC3, high-carbon is the safest choice.

In addition to the apply-feel issues discussed previously, temperature is an equally important consideration. When a smooth lining is used, the increased interface temperature created during lockup apply will not be removed, because there is no flow across the reaction surface. A smooth friction material that contains carbon is needed to handle the higher temperatures. In a non-lockup torque converter, a large volume of oil continually enters and exits the converter during operation. In a lockup converter the TCC piston acts like a one-way valve and stops the oil from exiting the converter when the TCC is applied. This prevents the heat from being removed from the converter by fluid circulation. Of course, no heat would be generated in the converter with an on/off clutch-apply strategy if the clutch were holding.

When the demand for better fuel economy increased, it became necessary to bring the clutch on earlier and keep it on longer. These demands also made it necessary to increase the slip rates of clutches for better drivability. The increase of slip rates also meant that heat was again being generated within the converter, even in the lockup mode.

Some manufacturers dealt with the heat issue by developing friction materials that were more heat resistant (carbon based). Some added controlled orifices to allow a portion of the oil to carry heat from the converter. These orifices allowed the oil to bypass the clutch and exit through the TCC-release-oil passage.

Some manufacturers even did both by changing the friction material and adding an orifice in the piston itself. One import manufacturer added an orifice in the piston of its rear-wheel-drive vehicles and did not add the orifice to the same clutch used in its front-wheel-drive vehicles. The 0.028-inch orifice found in several of the TCC pistons will flow 0.19 gallons per minute (gpm) at 80 psi at 150° F. (Figure 2). (Note: The 0.028-inch orifice is being phased out of most pistons because not enough heat was being removed from the converter to offset the loss of clamping force.)

Now consider that each of the eight radial grooves of the front-wheel-drive clutch in Figure 3 also will pass that same amount of fluid.

This means that more than 11/2 gpm of oil will leak past the clutch. When the vehicle is new, supplying the volume of oil necessary to offset a 11/2-gpm leak should not be a problem. But, as mileage on the vehicle increases, the transmission’s ability to deliver this high volume of oil decreases. Wear in the pump and valve-body bores will simply not allow the transmission to keep up with this type of leak. The OE has the advantage that as the transmission ages, the friction material also wears. The grooves become thinner and, therefore, pass less oil. When the aftermarket torque-converter rebuilder puts a new grooved clutch lining into his converter, he is restoring the 11/2-gpm leak in a transmission with lower volume capacity. This is probably why the OEs are replacing some of their grooved friction material with smooth linings in some remanufactured units.

Special thanks to Chris Horbach, chief application engineer/tech-support supervisor for Raybestos Powertrain.

Ed Lee is a Sonnax Technical Specialist who writes on issues of interest to torque converter rebuilders. Sonnax supports the Torque Converter Rebuilders Association. Learn more about the group at www.tcraonline.com.