Adjusting Clutch-Control Valves on the Aisin FWD 6-Speeds

Have you ever installed a TF80, TF81 or TF60 after overhaul and it has had harsh shifts or engagements, or maybe there has been a flare/bump upshift or harsh coast-down clunks? Most times, clearing the shift adapts and driving the vehicle to relearn the shifts will correct these annoying problems. After a good, long test drive to relearn the shift adapts, sometimes a shifting or engagement problem remains. Assuming that there is not excessive wear in the valve body and the linear solenoids are good, the clutch-control valves on the valve body can be adjusted to correct these problems.

Humming Along with the BorgWarner 4493/4494 Transfer Case

GM had great sales for a time with the Hummer brand. The economy has foreclosed on that segment of the market, and GM has sold the brand to a Chinese company. However, there are lots of Hummer H3s around and no dealer body to repair them, which sounds like opportunity for the transmission shop.

The Hummer H3 was available with either an automatic or manual transmission and used a 4493/4494 transfer case manufactured by BorgWarner. The 4493 and 4494 are operationally the same transfer case, a three-position, electrically shifted unit. The 4493 has a 2.64 low-gear ratio and the 4494 has a 4.1 low-gear ratio, which makes it a good rock crawler for the off-road guys. This obviously means that the internal gear trains will be different.

Let’s Talk about Adaptive Shift Strategy

The 604 was the first American computer-controlled transmission with adaptive shift strategy. The relearn process was not much different from what it is for today’s transmissions. For those of you who were not in the transmission industry back then, there was no quick-learn procedure for the 604. The quick-learn feature was not available until the mid-’90s. You actually had to drive the car at different throttle openings to relearn the shift adapts, and it could take 30 minutes or more of driving time to get it right.

4T65-E Valve-Body and Channel-Plate Identification

Let’s start with the valve body. Unfortunately, there are no casting numbers on the 4T65-E valve body for quick identification. The four most-common 4T65-E valve bodies are the early GM, late GM, early Volvo and late Volvo. There are more than four variations, and they can be found during the crossover years of 2002 and 2003. There are four questions that you need to answer to properly identify the valve body.

Overall-Height Issues and Pump-Gear Problems

Some GM vehicles with 4L60-E transmissions and 300-millimeter converters are experiencing higher-than-normal pump-gear failures. Affected vehicles are 2002-2003 Bravada, Envoy and Trailblazer (Dacco B-85 VJCX) equipped with the 4.2L engine. An easy way to identify this converter is that it is the only GM 300mm unit whose impeller overlaps the front cover rather than vice versa.

Manual Transmission Fails Because of Hydraulic Error

Manual Transmission Fails Because of Hydraulic Error

R&R Tech

Subject: Shifter sticks in fifth gear

Unit: NV4500

Vehicle Application: 2002 GMC 2500

Essential Reading: Rebuilder, Diagnostician, R & R

Author: Steve Logeman

Don’t Get Shook Up

Here is a trouble vehicle – a 1999 Chevrolet 4WD Silverado extended-cab pickup – suffering from a problem whose unique cause was difficult for us to find. The customer’s complaint was that the transmission-to-transfer-case adapter had cracked repeatedly. I don’t know the exact count, but by the time we were blessed with this job I think the count was three broken adapters. Figure 1 is an example of one of the broken adapters that was cracked near the transfer-case mounting bolts.

Why Resistance Checks Don’t Always Work

The example used here is a 1998 Oldsmobile Intrigue 3.8L with a 4T65-E transaxle that has a P0753 electrical code – 1-2 shift solenoid circuit – stored in the PCM; no other DTCs are present. The code will not set until the 1-2 solenoid is commanded to turn on. Now we have all seen the diagnostic flow chart for this code. No matter which repair-service publication you use they are all basically the same: Check resistance from here to here and here to here, from there to there and from here to ground, blah blah blah; I think you know what I mean. Then we print off a wiring diagram so we know what to look at.

4L60-E EC3 TCC Control and Adapt

While I was helping a co-worker repair a TCC slip, we analyzed some graphs and noticed some interesting info on how the PCM behaves and how it “sees” and adapts for a TCC slip.

Deal with High Current and Intermittent Failures

Tips for troubleshooting intermittent failures and no-starts

What is your knee-jerk reaction when a vehicle rolls into your bay with the following concern: intermittent no-start? Personally, I usually like to know the make and model of the vehicle so I can tag it with a pattern-case failure (and I will revisit this point a little later), but this can often lead me to dangerous and time-wasting conclusions.

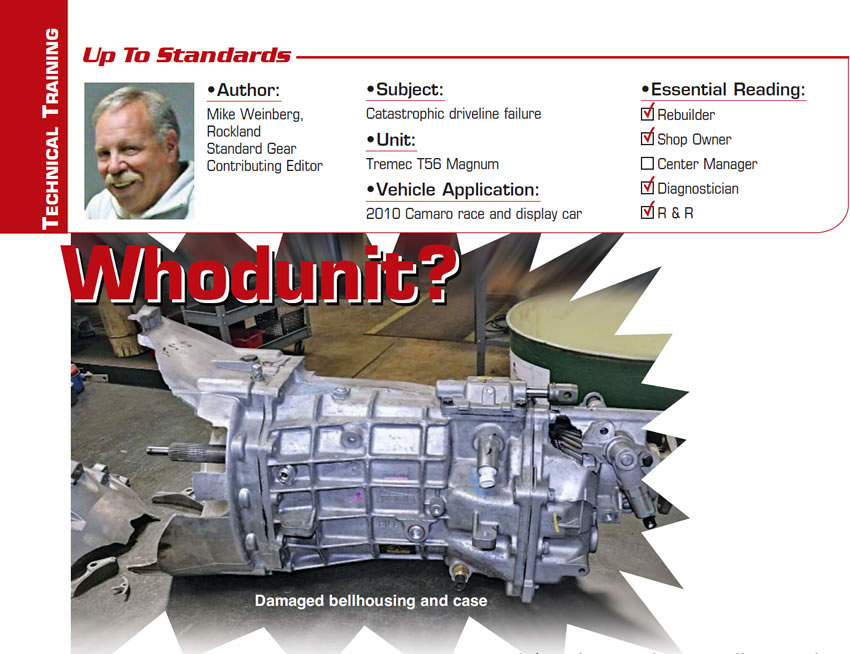

Whodunit?

Every technician who rebuilds transmissions has failures, which we call comebacks. We get the failed or improperly working unit back, diagnose the cause and make it right.

The entire exercise we go through on a daily basis making repairs is based on the same set of facts: We have to first diagnose the problem, understand the cause of the failure, correct that cause and then certify that the unit is working correctly and deliver the product.

Don’t Forget the Basics

Instead of choosing just one success story that applies to one vehicle, how about writing something that applies to all vehicles? The thought that I want to convey is to pay attention to the simple things and small details alike, both when diagnosing a problem and when removing and reinstalling a transmission.