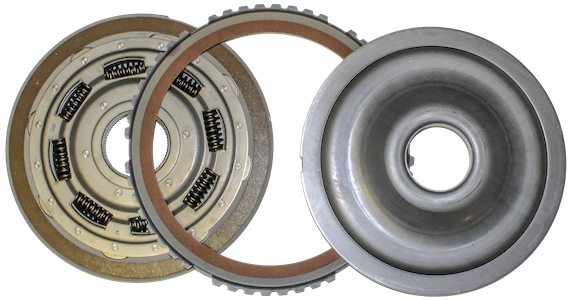

4R100, 5R110W Three-Piece Damper Assembly

Tri Component announces the availability of its three-piece damper assembly (p/n FX-23-45A) for 4R100 & 5R110W, 6-stud converters. Specifically machined areas prevent “wobbling” of the piston resulting in the elimination of turbine interference/noise common in the OEM assembly. The assembly is available in both bonded and unbonded versions. The friction material used is a Tri

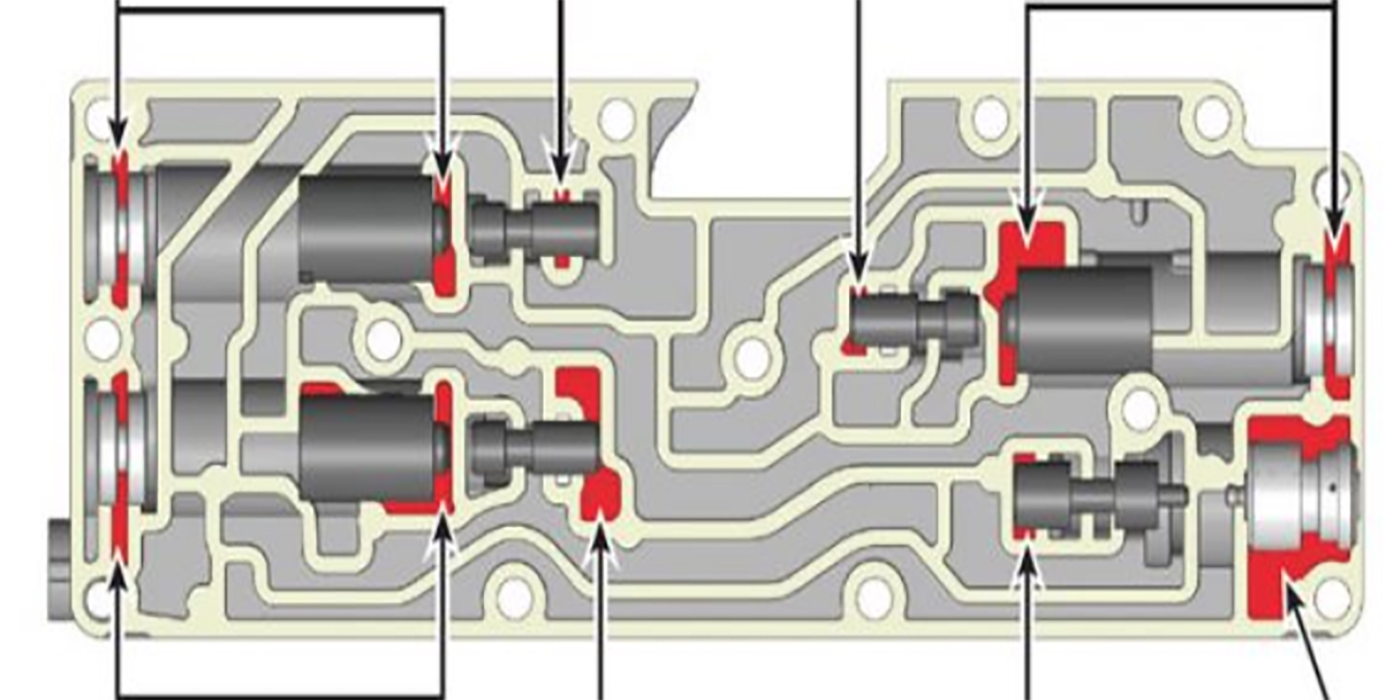

Ford 4R100 Direct, Intermediate Clutch Feed Seal Kit

TransTec’s Ford 4R100 Direct/Intermediate Clutch Feed Seal Kit fits 1996-UP transmissions (p/n 0049471821). This forward-thinking design helps prevent fluid pressure loss in the direct and intermediate clutch feed circuit, thereby avoiding premature clutch failure in the future. NOTE: TransTec overhaul kits 81000354, 81000140, and 71006415, built after 1/29/21, have been updated to include this kit.

OEM-style Drive Plate for the 4R100/5R110W

Tri-friction materials are tailored for the applications for optimum engagement characteristics and the longest life.

4R100 Torque Converter

New torque converters from WIT and Atlantic.

Tasc Force Tips: Ford E4OD, 4R100

Ford E4OD, 4R100

Critical Wear Areas & Vacuum Test Locations

Identifying Converter Components

Whether you are searching through a core pile or looking for a specific part to complete a rebuild, sorting out the various identifying features of Ford E4OD, 4R100 and 5R110W converters can drive you crazy. A six-stud version of each converter that happens to have the same K factor (impeller blade angle) will look almost identical. If you have not educated yourself on the subtle contour differences where the impellers mate to the impeller hubs, or cannot recognize the 0.200″ difference in the relationship of the pilot to mounting pad difference in the 5R110W compared to the E4OD and 4R100, you can become easily frustrated. The following are part-by-part differences, as well as some hints for identifying each one.

Understanding 4L80-E Overdrive Clutch Failure

Wintertime typically equals a parking lot full of snowplow trucks. Sometimes they represent repeat business — of the bad kind — but most of the time, new work.

The 4R100 with a Mysterious No 3-4 Shift

A friend of mine who owns a local transmission shop called me recently to see whether I could help with a difficult problem he was having with a transmission. He had taken in a Ford truck with a 4R100 transmission that had no fourth gear. The fluid was badly burnt and there was a lot of clutch material in the pan.

Quit Dimpling Those Converters

This all started with my looking at multiple converter failures caused by the converter bolts damaging the backs on Toyota A245E/A246E transmissions used with the 1.8-liter engine. We also see this in other Toyota applications, maybe more so than with other vehicle manufacturers.

My intentions were to order some factory bolts to get the proper dimensions and possibly send these reman units out with new bolts, either OE or an economical replacement bolt. I was hoping this would eliminate any confusion for the R&R technician as to which bolts were the proper ones to go into the converter, hence eliminating unwanted warranty repairs.

Getting (and Staying) Connected

Being the technical director for the valve-body and solenoid department, I’ve seen more than my share of errors and mistakes that people have made while working with automatic transmissions. The majority involve electrical components, most of them involving the connectors in some way. Often damage to a connector is done during the disconnection process. We’ve all been told not to wiggle a connector to get it off because it can expand the pin cavities in the connector and cause the pins to have poor or no connection when the connector is plugged back in; for example, in Chrysler 604s.

A Case of Mistaken Identity

Those of us in the business have seen all different kinds of oddball installations and strange diagnoses that make absolutely no sense. There are so many variables that can contribute to a problem, and finding the root cause is an ongoing challenge for all of us. To complicate things even further, if you don’t have the background story on the vehicle you’re trying to fix, you’re working with assumptions that can easily get you into trouble. This story is an example of one such repair challenge.

Installer, or Plumber?

Shortly after the installation, the company called our warranty department to report that the transmission was binding in both forward and reverse. It hadn’t been on the road yet because it would barely back out of the bay. They stated that it would roll only a few feet and the transmission would bind to the point of stopping the truck in both forward and reverse. Since our facility that sold the unit was a full-service shop, it was decided that it would be best for the utility company to bring the truck into our shop to diagnose and repair the problem.