TASC Force Tips

- Author: Tim LaCerra

Should you replace the valve body?

A Saturn with the TAAT comes into your shop with a delay, slip/bang or no reverse at all. What is the first thing you do? Get a valve body. It’s always the valve body. The only thing that goes wrong with a TAAT unit is the valve body. We can do this in an hour or so.

Since starting VBX five years ago, we’ve heard all those lines, and more. Now, granted, if a TAAT has 60,000 miles or more on it, the odds are very good that the pressure-regulator valve and bore are worn significantly. A repair or replacement valve body is no doubt in order. But after the repair or replacement, you still have an issue. It must be a flaw with the repair, or a defective remanufactured valve body, right? Not necessarily. Let’s explore a few other things that could cause a reverse issue.

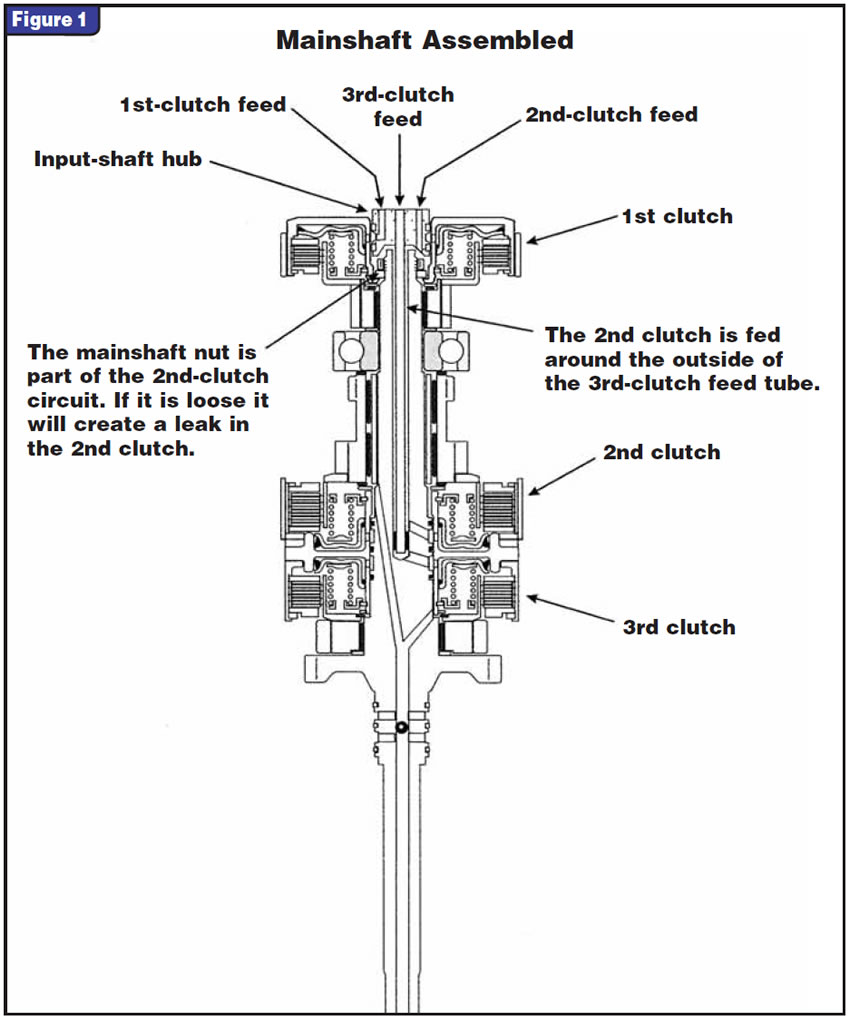

The most-common cause of delay or no reverse, other than the valve body, is a loose mainshaft nut (see Figure 1). The symptoms most likely will occur when the vehicle is hot, and there also may be a soft or flared 2nd-gear upshift. According to ATSG’s 2003 seminar information, a loose mainshaft nut can cause a leak in the 2nd-clutch circuit. When the nut is loose, the mainshaft walks back and forth in the middle of the case. This causes a small gap between the 1st clutch and the nut, which is where the leak in the 2nd-clutch circuit appears. A new mainshaft nut should be included with every repair, since it has a factory thread locker. The nut can be accessed by removing the side cover, which means the unit does not have to be removed to replace it. The nut – and this is very important – should be torqued to 111 lb.-ft. The Saturn part number for the mainshaft nut is 2100680.

Another common no-reverse condition is a faulty or defective vehicle speed sensor. The input from the VSS to the PCM should always read less than 5 mph. This allows the PCM to command high line pressure, which in turn will move the servo apply valve (1993-up models only) to an open position, thus opening the passage to allow oil to the forward/reverse servo piston. If the VSS is defective (thus reading 5 mph or above on your scan tool), the PCM will command low line pressure, thus not feeding oil to the forward/reverse servo piston. In turn, the slider assembly will not move, causing a no-reverse condition.

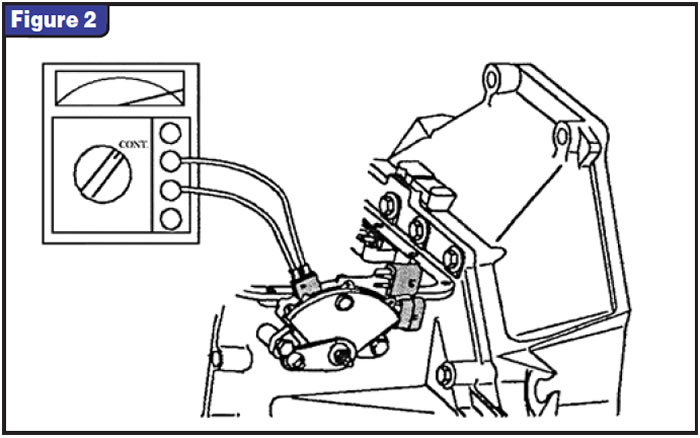

Another problem that occurs, especially when the unit has been removed, is an incorrectly adjusted pattern-select switch, which we all commonly know as the manual-lever-positioning switch. If the pattern-select switch is not adjusted properly, a no-reverse condition and loss of drive and/or erratic or harsh shifting can occur. To adjust the pattern-select switch, according to the ATSG service information, put the selector in the D4 position. DO NOT start the vehicle. Connect an ohmmeter to the switch (see Figure 2). Rotate the switch until the ohmmeter reads continuity. Once a reading is obtained, tighten the pattern-select switch.

Again, the valve body is still the main cause for both reverse and forward issues with the TAAT. But as you can see, there can be other areas that you also may need to address.

Thanks to ATSG and its Technical Service Information, and to Bob Gibson, senior technical adviser at VBX, for assistance with this article.

Tim LaCerra is the president of VBX-ValveBody Xpress and a member of the TASC Force (Technical Automotive Specialties Committee), a group of recognized industry technical specialists, transmission rebuilders and Sonnax Industries Inc. technicians. ©2007 Sonnax