Up to Standards

- Subject: Using the proper lubricant

- Units: BorgWarner, New Venture transfer cases; Tremec 3650 transmission

- Essential Reading: Rebuilder, Diagnostician, R & R

- Author: Mike Weinberg, Rockland Standard Gear, Contributing Editor

The lifeblood of any machinery with moving parts is the lubricant. Without the proper lube, serious failure occurs quickly, yet few technicians have taken the time to really understand such an important commodity. Just as parts have proliferated dramatically with so many transmission and transfer-case designs in the market, the different specified lubricants are now almost too numerous to stock.

Failure to use the correct lube will at worst cause an expensive comeback and at best add to your day with phone calls and more work.

In days gone by there were three types of oil that covered basically every vehicle that could come in the shop: Dexron ATF, Ford Type F ATF and 90-weight gear lube. Occasionally a shop would need some posi-traction additive for a limited-slip differential. Dexron took care of GM and Chrysler transmissions, and Ford Type F went into Henry’s products. Ford was slick with Type F fluid, as it saved itself a lot of money by raising the coefficient of friction in the fluid and eliminating one clutch per pack in the design.

Today we have dozens of required oils that should be in any shop’s inventory. We have to worry about the proper viscosity, the proper coefficient of friction for the design and the proper amount of fluid to use. In manual transmissions, transfer cases and differentials, there is good cause to worry, as warranty issues are never very far away.

In times past most stick transmissions, transfer cases and differentials operated on 90W gear oil. This heavy lube created cold-shift problems during winter driving, and the vehicle manufacturers got tired of the complaints, so they shifted to ATF in many designs. The ATF got rid of most of the cold-shift complaints, but no good deed goes unpunished. Design modifications to improve synchronization and provide smoother shifting created a number of new issues.

Gone were the typical brass or bronze synchro rings, and now more-exotic materials began to show up on the rings. Paper-lined rings, which had a composition similar to clutch plates on automatic units; carbon fiber; Kevlar; and sintered metal of various types had arrived. All of these required a lubricant with a specific coefficient of friction to make the unit shift smoothly and correctly. A synchronizer ring is a wet clutch, needing to apply friction to the cone of the speed gear to speed it up or slow it down until the driveshaft speed matches the input-shaft speed for a smooth shift.

The new materials on the rings are porous and absorb fluid, which creates a real nightmare if an incorrect fluid is used. Correcting this problem may take 500 miles of driving with the correct lube in place or may necessitate disassembly of the unit and installing new parts. Either way it is a big hassle for being ignorant of the fluid requirements.

Another issue came up with the increased use of ATF in manual transmissions and transfer cases, and that is the vanishing fluid. ATF, because of its lower viscosity, tends to get aerated and form a mist that can exit the transmission vent, causing low-fluid failures. This is common in M5R1 and M5R2 transmissions and in 231 and other transfer cases.

Most manual transmissions and some transfer cases are “splash lubricated” as oil is moved around inside the case by the moving gear train with no pressurized lube system. It is a rare customer who will check the oil on a standard transmission, transfer case or differential. By the time you are asked to check it in your shop it is game over. This means that you need to either get your customers in for more-frequent preventive maintenance or change the fluid characteristics to protect your warranty.

On New Venture transfer cases that do not have pressurized lube systems or internal clutch packs, changing the lube spec to 5W30 motor oil will prevent misting and eliminate shift or engagement problems. 5W30 synthetic motor oil is the proper lube fill for NVG 207, 208, 219, 228, 229, 231, 233, 241, 242, 243, 249, 261 and 271 transfer cases.

Notice I said “synthetic.” Oil is oil; the petroleum never dies, but the additive package goes away. Heat and oxidation occur at operating temperatures, and the various additives in the fluid begin to fail. The friction modifiers, surfactants, extreme-pressure additives and anti-foaming qualities all vanish from the oil under high heat and heavy traffic. Synthetic oil is petroleum that has been hydro-cracked during manufacture, giving it longer and stronger molecular chains that enable the fluid to withstand higher heat before losing the additive package.

The following BorgWarner transfer cases use a pressurized lube system with an internal shaft-driven oil pump and must use ATF: 1345, 1350, 1354, 1356, 1370, 4401, 4405, 4406, 4407 and 4411. A number of New Venture transfer cases are driven by clutch packs internal to the transfer case to apply torque to the front axle. For proper operation in the 136, 236, 246 and 247 series as well as other newer models, stick to the factory-recommended lube for chatter-free operation.

For computer-controlled, clutch-operated transfer cases, you need to specify on your warranty that the customer must have the oil changed once a year or every 12,000 miles. The clutches generate a lot of heat during the duty cycle, and this shortens the life of the additive package in the lube. Using an incorrect lube will have unpleasant clutch chatter as a side effect.

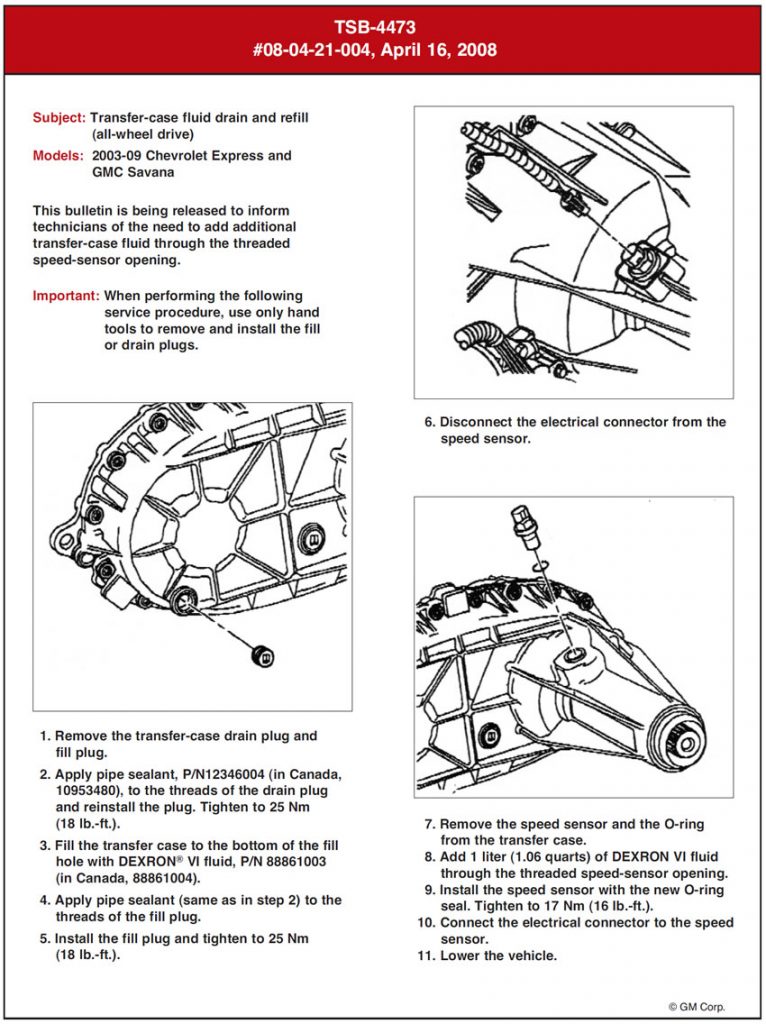

Along the way design failures in certain units have caused premature failure or shift complaints. The most glaring of these is the BorgWarner 4473 used in the GM Express and Savannah vans. It was designed with the fill plug too low on the case to allow this all-wheel-drive unit to be filled sufficiently. The accompanying illustration provides the procedure for filling the case. The basic issue is that when filled to the level of the plug it is about a quart low. The fix is to fill the unit, tighten the fill plug and then add one more quart through the speed-sensor opening.

Another design problem, in the Tremec 3650 transmission used in late-model Ford Mustangs, is the opposite of the 4473 issue. If you fill a 3650 to the spill line, it will have too much fluid in it. This creates a problem called “windage” – the effect of too much oil slowing the gear train prematurely during a shift and changing the synchronizer timing, resulting in notchy, dragging shifts. The fix here is to fill this unit to 1/2 inch below the fill plug.

Racing and performance engines use windage trays, or crank wipers or dry-sump systems, so that the crankshaft does not run through the oil in the sump or pan, which robs the engine of some power because of the increased parasitic drag on the crank. Try running on a beach next to the tide line and then try running in a foot or more of water and you will understand the additional effort required.

Lubrication is anything but simple. The quantity, quality and type of oil specified for each unit is critical to the its proper operation and longevity. Do not take chances; get the right oil. I know on a Friday afternoon with a customer ringing your phone off the hook it is tempting to use anything handy. Don’t do it, as the downside is expensive and unpleasant.

Many shops are now stocking the correct oils to make sure that the job can leave on time with no problems. Most suppliers will be able to furnish special oils to you with your parts order. If yours doesn’t maybe it is time to make a change, as the lubricant is a necessary part of the repair.