Up To Standards

- Author: Mike Weinberg, Contributing Editor

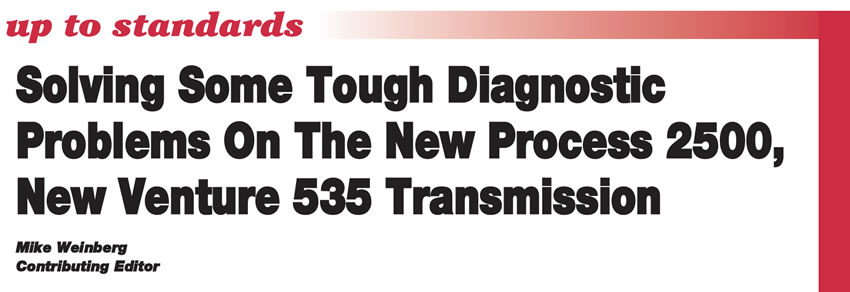

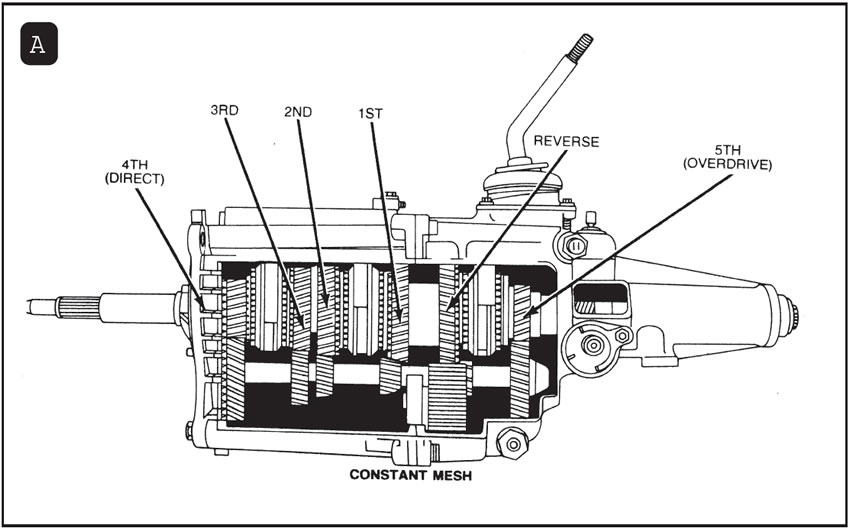

The New Process 2500 transmission, also known as the New Venture 535 transmission. is an aluminum-cased 5-speed, rear-wheel-drive unit introduced by Chrysler in 1987 and produced through 1992. The unit has a top-mounted shifter and a 4-bolt aluminum top cover and was spec’d to use 10W30 motor oil as a lubricant fill. This unit was found in B/AB Ram Van/Ram Wagon, D/AD Ram pickup/Ramcharger/Ram Cab & Chassis, and N/AN Dakota, Dakota Sport/Dakota Convertible. This design has created some noise and shift problems that have been difficult to solve. This article addresses these complaints and what will fix them.

As per good diagnostic procedure it is most important to correctly verify the customers complaint before removing the unit from the vehicle. The main complaints caused by this unit are shift performance and noise. If the vehicle is drivable, make sure you take a road test with the customer and let the customer drive to verify the complaint. Bad driving habits by the customer will be responsible for some noise and many shift complaints. Gear rattle may easily be induced by a customer upshifting too early and lugging the vehicle. Gear clash can be caused by not fully depressing the clutch pedal or improper timing of the clutch and gear shift lever by the driver. An owner who likes to “ride” the clutch, resting his foot on the pedal while driving may create release bearing noise and premature clutch failure. By checking the driver along with the vehicle you may save yourself some wasted effort.

Shift Performance

High-effort shifts may be found in cold weather driving, which is considered anything below freezing. The factory fill for this unit is 10/30 motor oil. If high-effort shifts are encountered followed by smooth operation when the vehicle warms up, change the lube fill to Dexron II. Road test the vehicle again after it sits overnight in the cold to verify that the problem is solved. Using Dexron II ATF will not create any durability concerns.

After an overnight stay in freezing weather the trans slips out of gear by itself. This can occur with the clutch pedal depressed or on coast conditions This is not an internal problem, but rather the shifter boot becoming so stiff in the cold that it loses flexibility and pulls the stick back out of gear. Chrysler released a stiffer set of detent springs, part #53006659 to prevent this problem. Chrysler Technical Service Bulletin #21-11-89 addresses the repair procedures.

High-shift effort or gear clash in warm weather can be caused by clutch problems or internal damage to the unit. Carefully check the clutch hydraulic system thoroughly for proper fluid level, leaks, master and slave cylinder operation and worn or bent pedal linkage. Test the clutch spindown time, which should take no longer than 5 seconds. A prolonged spindown time can indicate a binding pilot bearing, rusted or damaged clutch splines, a bent or damaged clutch disc, low trans fluid level, or a misaligned bellhousing. Chrysler has Technical Service Bulletins #06-01-89 and #06-03-89 dealing with these problems.

Transmission Noise

This gearbox has a long history of noise problems. Noise being one of the most trying problems we deal with needs to be diagnosed carefully. If you are quick to remove the unit before you are sure, it will be a big time waster. Nobody can see a noise. Check that the lube fill is the correct type and up to the fill line. Make sure that the shift lever boot is not torn or missing allowing road noise to be mistaken for a gear or bearing problem. In many instances a bad release bearing will be misdiagnosed as an internal problem.

The two main causes of noise in this unit is a misaligned bellhousing and a countershaft that is set up too tight. The repair manuals state that the countershaft endplay should be set to 0.001-0.005. Having remanufactured hundreds of these units, I can tell you from painful experience that anything tighter on the countershaft endplay than .0020-0.0025 will give you a noisy gear box. This is one unit that is quieter loose than tight. I am sure that the factory specs work well within the manufacturing framework, but after thousands of miles of warp and wear, loose cures the problem.

The second common cause of noise is a warped or misaligned bellhousing. Dial indicate the bellhousing and check run out. To do this mount the bellhousing to a clean corrosion-free block surface, center up a dial indicator on the crank flange and indicate the opening for the front bearing retainer. The run out of the bellhousing should be less than 0.003 We have seen brand new bellhousings that did not run true. The fix for this is to loosen the bellhousing bolts slightly and to use starter shims in 0.005 and 0.0010 to properly align the bellhousing. There is no shortcut here and be sure to bill properly for your time. Reinstall the transmission and road test. Do not be surprised if the unit is still noisy, because if the unit even freshly rebuilt, was run for a period of time with a misaligned bellhousing, the input to main shaft pilot rollers may be flattened out due to the pressure put on the input due to the misalignment. We have seen a number of these units that have been returned shortly after installation with a warranty claim, and the only damage found in the unit is pilot rollers that are flattened out on opposite sides of the roller, in other words a small flat on opposite ends of the roller 180° apart. Never install one of these units without dial indicating the bellhousing. The short time it takes to get the alignment correct will save you endless hours of aggravation.

This transmission like any other will suffer from noise and driver induced failures that result in broken gears, worn out synchronizers, worn or contaminated bearings. The problems usually start after the gearbox is repaired because alignment and other causes listed here were ignored. It is easier to do it right the first time.