Al Varner Jr. was “born with transmission fluid on his bib,” according to those around him. Hanging around his dad’s shop, he had an early introduction to the industry, tearing down transmissions at age 8 and building his first transmission when he was 14.

“I was definitely born and raised in his business,” he says. “Every day is a different adventure. Every day, I learn something new. It always changes and that’s what I like about it. Some people, that’s what they hate about it. But that’s what I like about it because I never get bored. If I did the same thing over and over, I would just get bored and would hate it.”

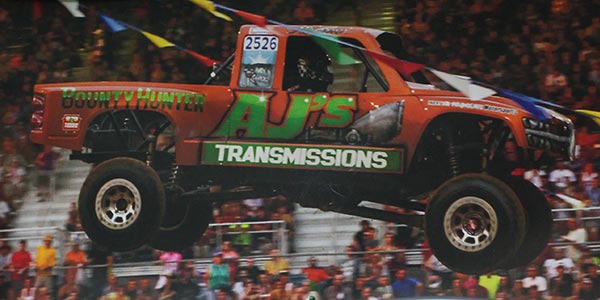

For 26 years, Al Varner Sr. owned and operated a shop called ATPA in Green, Ohio, but by 2013, it needed to grow but didn’t have the space to do so. So Al Jr., by then the shop foreman, bought everything from his father and relocated the company to Waterloo Road in east Akron, where it became AJ’s Transmissions.

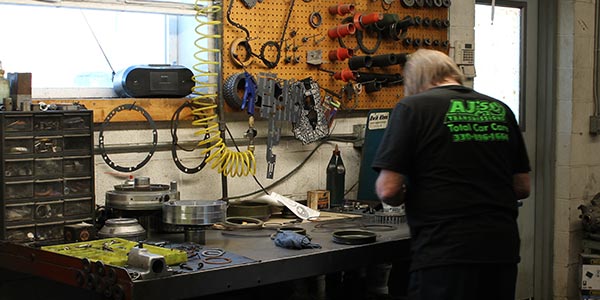

The shop has seven employees other than Al Jr.: two builders (including Al Sr.), four technicians and an office assistant. They are transmission-focused specialists, working on all makes and models, but in the last year and a half they’ve added a bit of general car care to the mix.

“I don’t advertise for it,” Al says. “It’s basically just my regular customers wanting us to do all their work. We’ll do timing chains, we’ll fix motor leaks, whatever they need, because a lot of our customers really trust us, we’ve got really good relationships with them and they just kept asking.”

Cars are the main focus of AJ’s Transmissions—they work on the occasional bus or medium-duty truck, but typically only in the summer when they can be worked on outside where there’s more space. As Al says, the space taken up by one bus or truck lift could hold two car lifts, so there’s no question which is more profitable for the business.

For the most part it’s typical transmission work—rebuilds, transfer cases, rear end work, etc.

“We do a lot of differentials,” he notes. “Most people around here don’t do differential repairs. So we’re one of the last few shops that will.”

The business

Business has been very good, Al says.

“We’re having problems getting parts right now, but business has been great. I know a lot of people have been suffering with COVID and everything, but we were actually a business that’s been very fortunate.

“People are fixing stuff that they wouldn’t fix before. We’ve been running anywhere from 40 to 50 cars at a time on our premises for the last year and a half. That’s fantastic.”

This has all happened despite the parts shortage which has affected the entire industry. Al says this shortage has been a headache but it’s been manageable.

“The jobs are still getting done, it’s just taking longer,” he says. “The job gets set aside until we get the parts. So, unfortunately, it does hurt the customer a little bit because they’re without their vehicle a little longer. It also keeps my racks tied up a little longer, which is not perfect for either one of us. But in the times that we’re dealing with and the cards that we’re being dealt, we just handle it the best way we possibly can.

“I spend a lot more time on the phone, searching for parts, locating parts, checking up on them, making sure that they are being shipped and they are in process. I’ve never tracked so many tracking numbers in my life than I have here in the last year.

“So it’s definitely more work,” he concludes. “We haven’t come across a time yet that we haven’t been able to at least get the car fixed. We’re still getting them done; it’s just a little more work and a little more time.”

The staff

Al credits his strong staff for much of the success of AJ’s:

“I’ve got a very good crew with me now; all reliable guys that show up every day. We’ve been really fortunate to have good mechanics. So that’s helped us a lot. And that’s what makes us different from most shops because we haven’t really suffered on staff.”

The technician shortage has been well-documented in the industry, but Al says his shop is the rare one that hasn’t been affected.

“Most of my guys stay with me for a long time,” he says. “One mechanic has been with my family for almost 30 years. We’re all here to make money and that’s what we do; we want to put food on our plates for our family. But I try to make it so that it is enjoyable. I don’t want anybody to hate their job. I don’t want to hate my job, right? If I hated my job, I wouldn’t want to come in here either. It’s the same way with them. We try to be kind of like a small family here.”

Al says he finds most of his employees via word-of-mouth, rather than posting ads online or anything along those lines. According to Al, the reputation AJ’s has built up is strong enough to attract exceptional employees.

“When they come to me, they’re looking for a certain type of place to work or a certain job,” Al says. “Two of my guys came from other companies that have closed and they were referred by previous mechanics. The only time I lose a mechanic is either they pass away, they retire or they move out of state.”

“I just want to have everybody like their job and I think that atmosphere and that attitude rolls over and it makes them want to stay here; it makes them want to grow and be a part of the company,” he explains, “because it seems like they all have pride in what we’re doing here. And that makes a huge difference.”