Issue Summary:

- A 1995 or earlier Isuzu, Chevy or GMC truck with the JR403E may have no engine-braking assist from the exhaust-brake system and also may have an intermittent no-crank condition and/or difficulty starting.

- A Honda vehicle may come into the shop with code P1298 in addition to one or more solenoid codes stored.

- On a 2003-04 Honda Accord, 2002-04 Element or 2002-04 CR-V with automatic transmission, the manual shift lever cannot be moved from the park position after replacement of the throttle body.

- After replacement of the EPC solenoid in a Ford 4R70W/4R70/75E, the transmission slips or chatters at times. A line-pressure check reveals erratic line pressure.

The truck will have no engine-braking assist from the exhaust-brake system and also may have an intermittent no-crank condition and/or difficulty starting.

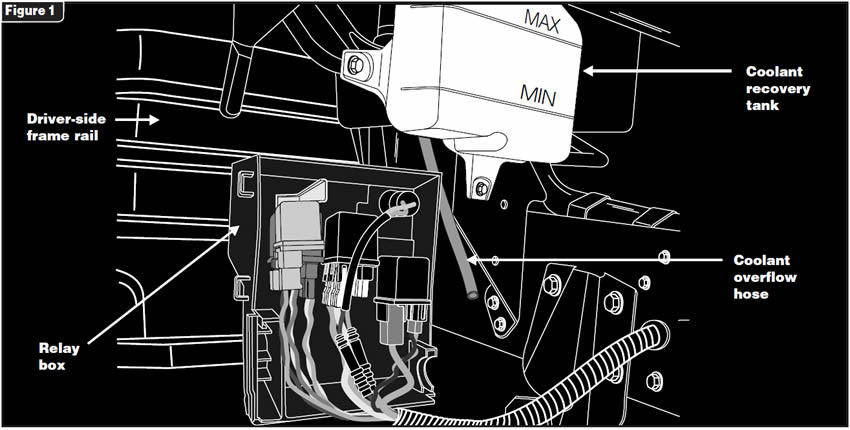

The coolant-recovery tank is mounted on the frame rail over a relay junction box as shown in Figure 1. The relay box usually has a cover over it to protect it from the elements and other sources of contamination. The cover has a bracket to hold the overflow hose in place. At some point the relay-box cover is not re-installed or has fallen off, allowing the overflowing coolant to blow into the open relay box.

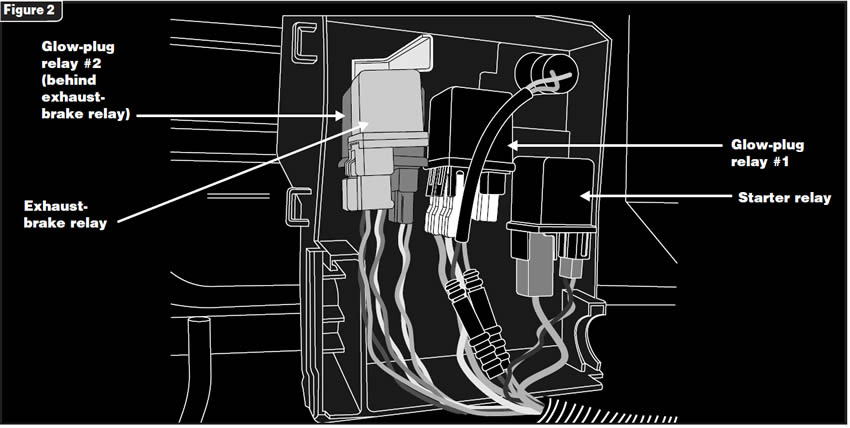

Contained within the relay box are the exhaust-brake, starter and glow-plug relays (see Figure 2). Depending on which relay gets corroded and no longer has electrical contact with its circuits, one or more of the complaints mentioned will occur.

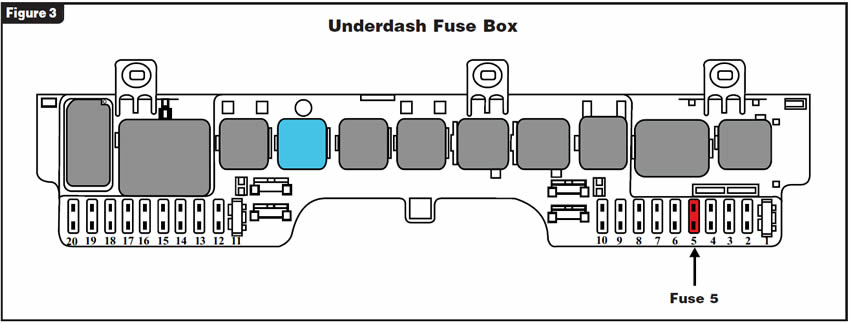

Should water contamination compromise the glow-plug relays, the No. 5 fuse in the under-dash fuse box (see Figure 3) will blow.

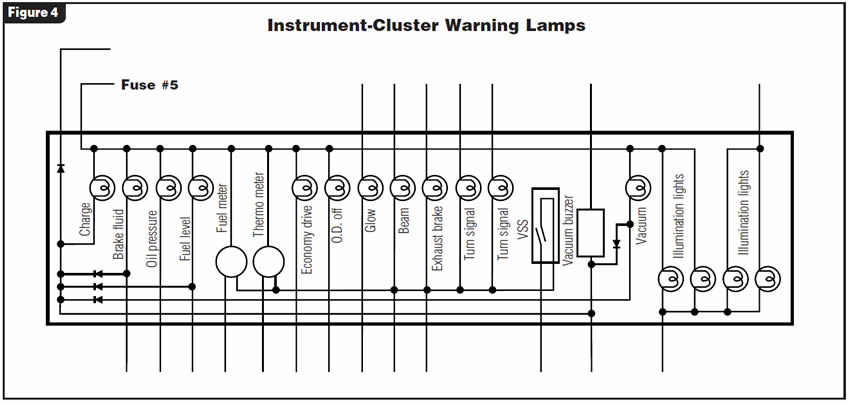

The No. 5 fuse supplies power to relays and to many of the instrument-cluster indicator and warning lamps (see Figure 4).

Once the damaged relays are replaced and electrical integrity is restored, some attempt should be made to protect the relay box from future contamination.

About the middle of the 1995 model year this relay box was moved to the outside rear of the cab. It is vital that the relay-box cover be in place, as there would be nothing to protect the relays from inclement weather.

Relays and relay-box components are available from RC Truck Parts at www.rc-truckparts.com or 305-863-3933.

The vehicle may come into the shop with complaints of code P1298 stored (ELD [electronic-load-detector] voltage high) and the TCM/PCM may store one or more of the following solenoid codes: P0753, P0758, P0763, P1768 or P1773.

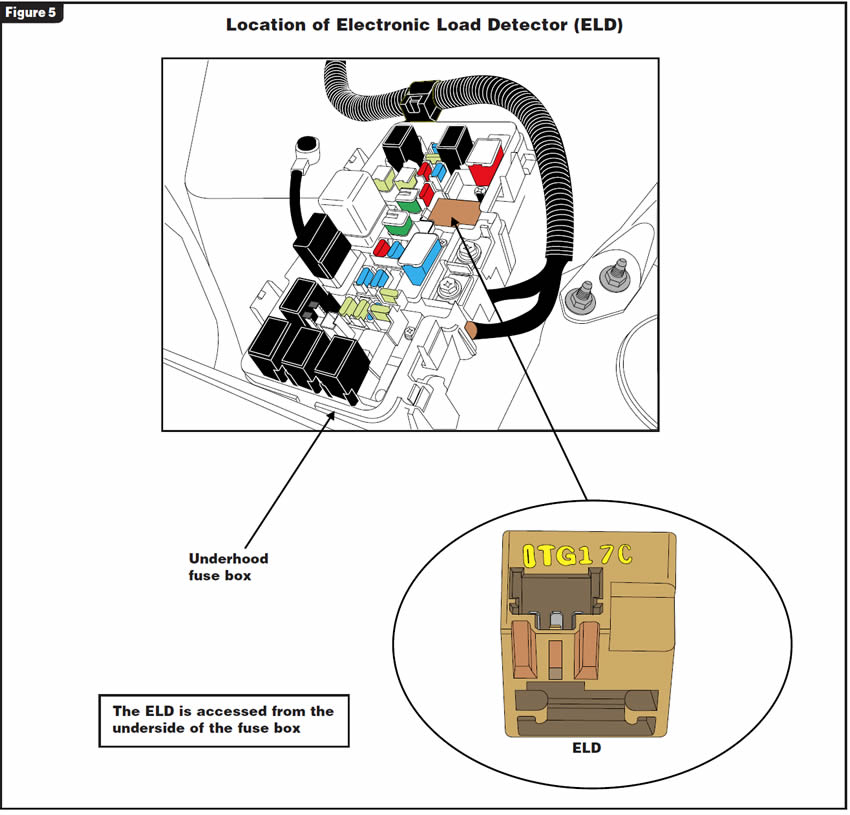

The ELD, in the underhood fuse box (see Figure 5), has failed, allowing the alternator to overcharge. This causes high system voltage and results in false solenoid codes being stored.

Note: These complaints also can be caused by failure of the #15 fuse on earlier models or the #4 fuse on later models, both of which are in the underdash fuse box.

The #15 fuse usually blows on Civics because of a wire harness under the intake manifold rubbing through the insulation and causing a short to ground. When this fuse blows, the transmission will be stuck in 4th gear, the ELD will not have power and the speedometer will be inoperative.

You could easily misdiagnose the ELD failure if you don’t know how it operates. The ELD limits the amount of alternator output voltage when it senses no electrical load. This puts less load on the engine at idle for emission-control purposes and provides better fuel economy on the highway. Under this “no load” condition a voltmeter across the battery may show open post voltage only (12.6V). Turn the headlights on, and now the voltmeter would indicate about 14.6V.

The transmission problems occur because of high-voltage conditions caused by high alternator output as a result of a failed ELD, which explains the P1298 code definition of ELD circuit high.

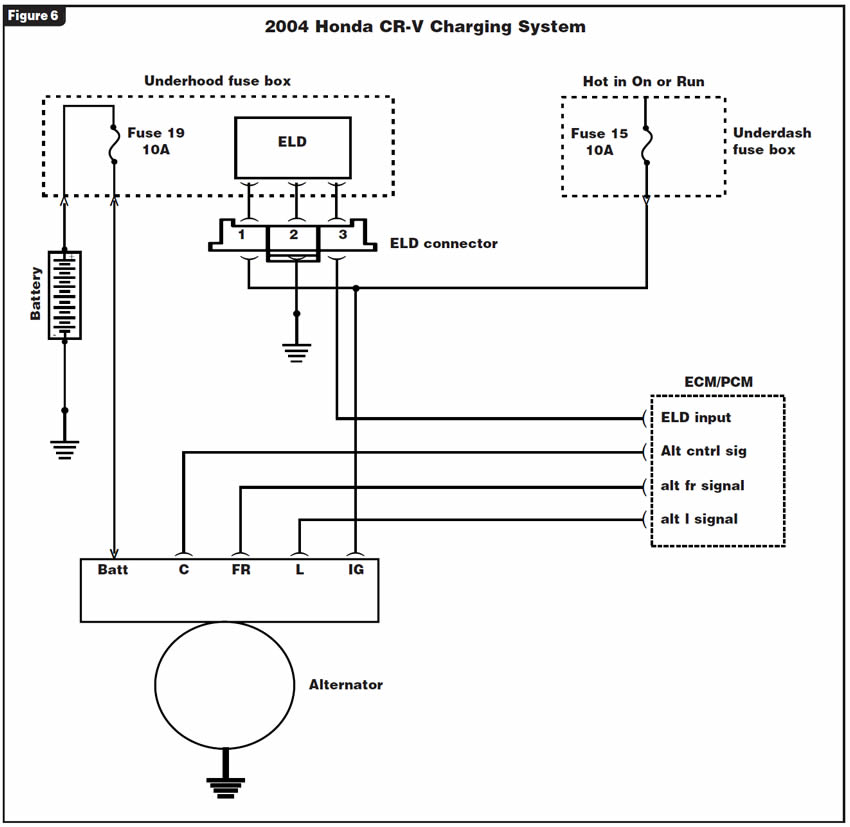

Always diagnose the P1298 code first. Start by verifying proper alternator output. The ELD connector, on the underside of the underhood fuse box, is a three-terminal arrangement that is shown in the wiring diagram in Figure 6. Terminal 1 is the battery-voltage supply for the ELD, which is fused by the #15 or #4 fuse that was discussed earlier. Terminal 2 is ground. Terminal 3 is ELD voltage output, which should drop with the headlights on.

If the voltage does not drop, the ELD is faulty. If the voltage does drop, the ECM may be at fault.

You can buy the ELD separately for some models, but on others you must buy the entire underhood fuse box; check with your local Honda dealer.

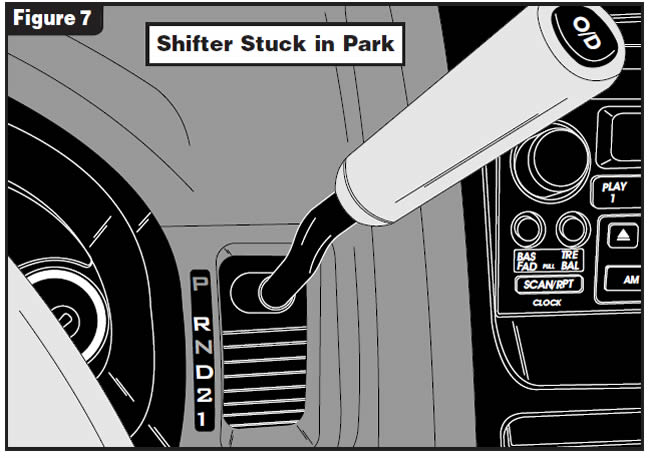

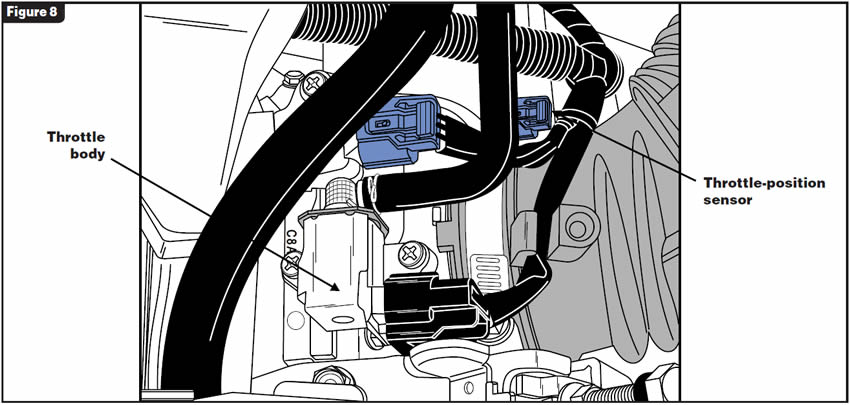

This bulletin applies to 2003-04 Accords, 2002-04 Elements and 2002-04 CR-Vs with automatic transmission. The manual shift lever cannot be taken out of the park position (refer to Figure 7).

The only previous work done was replacement of the throttle body (refer to Figure 8).

Whenever the throttle body is replaced on these vehicles, the PCM needs to relearn the relative throttle position.

Before the PCM can relearn the relative throttle position you must check the throttle-position-sensor voltage with key on, engine off. With a voltmeter the idle TPS voltage should be 0.49 volt. The scan tool should indicate zero percentage of throttle opening at this voltage.

If the TPS voltage is greater than 0.49, make certain that the throttle and cruise-control cables are not out of adjustment.

If the voltage is correct but the percentage of throttle opening on the scan tool is higher than zero, reset the PCM adapts with a capable scan tool or a battery disconnect and “brain-dead” the PCM.

Caution: Make sure you have the radio anti-theft code before disconnecting the battery.

After battery reconnect, perform the idle relearn. The idle relearn must be performed after any of the following has been done:

- A battery disconnect

- Replacement of the PCM or removal of the PCM connector

- Resetting of the ECM

- Replacement of the throttle body

- Replacement of the idle air-control valve

- Removal of the #6 15-amp PCM fuse from the under-hood fuse box

- Removal of the #19 80-amp battery fuse from the 4. Replacement of the throttle body

- Replacement of the idle air-control valve

- Removal of the #6 15-amp PCM fuse from the under-hood fuse box

- Removal of the #19 80-amp battery fuse from the

- Removal of the PGM-FI main relay #1

- Removal of any of the under-hood fuse-box wiring or connectors

- A disconnect of the main engine harness

- A disconnect of the G2 ground from the transmission housing

- A disconnect of the G1 ground from the body

- A disconnect of the G101 ground from the cylinder-head cover

The relearn procedure follows:

- Make certain all electrical items are off.

- Start the engine and hold the idle at 3,000 rpm, in park, until engine temperature reaches 194° F (90° C).

- Let the engine idle for about 5 minutes with the throttle fully closed.

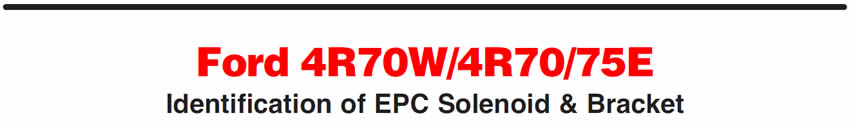

After replacement of the electronic pressure-control (EPC) solenoid, the transmission slips or chatters at times. A line-pressure check reveals erratic line pressure.

An incorrect EPC solenoid was installed. It did not match the solenoid retaining bracket.

The latest-design EPC solenoid has a black connector and requires the newly designed retaining bracket. If either of the previously designed EPC solenoids (tan or green connector) is used with the newly designed retaining bracket, the solenoid will not be positioned correctly in its bore, resulting in a loss of line pressure.

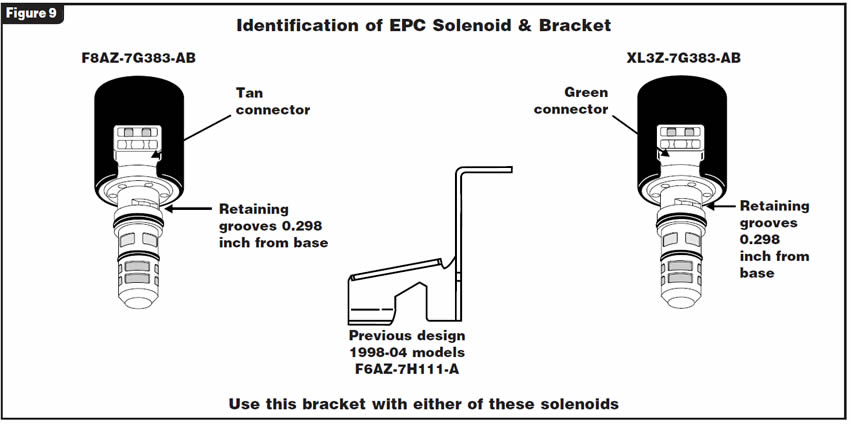

The EPC solenoid with the tan connector and part number F8AZ-7G383-AB and the EPC solenoid with the green connector and part number XL3Z-7G383-AB require the retaining bracket with part number F6AZ-7H111-A (see Figure 9).

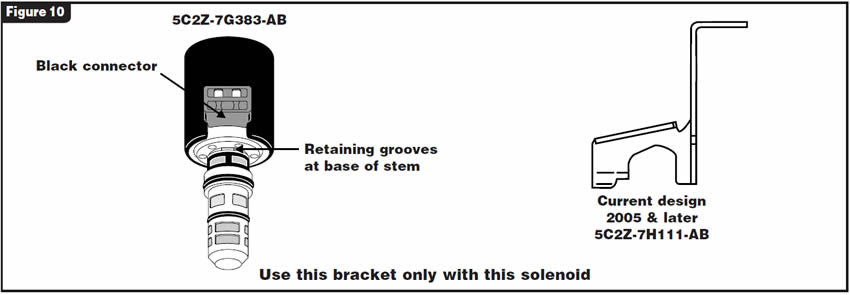

The newly designed EPC solenoid with part number 5C2Z-7G383-AB requires the newly designed retaining bracket with part number 5C2Z-7H111-AB (see Figure 10).

The retaining groove on the newly designed solenoid is at the base of the stem; the retaining grooves on the solenoids with tan and green connectors are positioned 0.298 inch from the base of the stem.

Although the F8AZ solenoid is listed for 1998-2000 models in most parts manuals and the XL3Z solenoid is listed for 2001-2004, the XL3Z solenoid actually can be used on 1998-2004 models, with the only difference being that the XL3Z solenoid has a slightly higher line-pressure response on the heavy-throttle end of the spectrum. The 5C2Z solenoid must be used on 2005-and-later models.

- 1998-2000 EPC solenoid with tan connector . . . . . . . . . . .F8AZ-7G383-AB

- 2001-2004 EPC solenoid with green connector . . . . . . . . .XL3Z-7G383-AB

- 1998-2004 EPC solenoid retaining bracket . . . . . . . . . . . . . .F6AZ-7H111-A

- 2005 & later EPC solenoid with black connector. . . . . . . .5C2Z-7G383-AB

- 2005 & later EPC solenoid retaining bracket . . . . . . . . . . .5C2Z-7H111-AB

September 2007 Issue

Volume 24, No. 9

- Isuzu/Chevy/GMC JR403E, 1995 & Earlier: No Engine-Braking Assist/No Crank or Hard Start

- Honda: Code P1298 Diagnosis, ELD Circuit High

- Honda: Shifter Stuck in Park

- Ford 4R70W/4R70/75E: Identification of EPC Solenoid & Bracket