This article is a “case study,” but the procedure used to find the root cause of this issue can be used on almost any application. We’ll use the scope module part of the Snap-On Zeus scan tool; is this the best scope out there? No, but the ease of use and the addition of the “guided component tests” make it a more straightforward process for technicians that are not used to using a scope.

We had a customer visiting family in town, and their 2005 Jeep Grand Cherokee started intermittently going into failsafe mode about 100 miles outside of town. While listening to the radio, they heard a commercial for a transmission shop that claimed they fix your transmission, not just sell you a new one. This is where the story begins.

The shop checked the Jeep out and told the customer, essentially, “the transmission has a solenoid code. This solenoid is part of a ‘solenoid pack’ that needs to be replaced and is much less expensive than a new transmission.” The customer gave authorization for the repairs to be completed. The vehicle is returned to the customer, and the next day a code is set. The transmission went into limp mode again, so the customer returned to the shop.

At this point, the customer lost faith in the repair shop. The adviser said, “We already replaced the solenoid pack, so it must need a computer. The bad solenoid must have damaged the computer.”

The customer declined the repair and did a web search for transmission shops. Focusing on the best-rated shops in the area, the customer found one of our shop locations. When the customer arrived and told us the whole story, we told her that we would accurately diagnose her concern and guarantee the repairs.

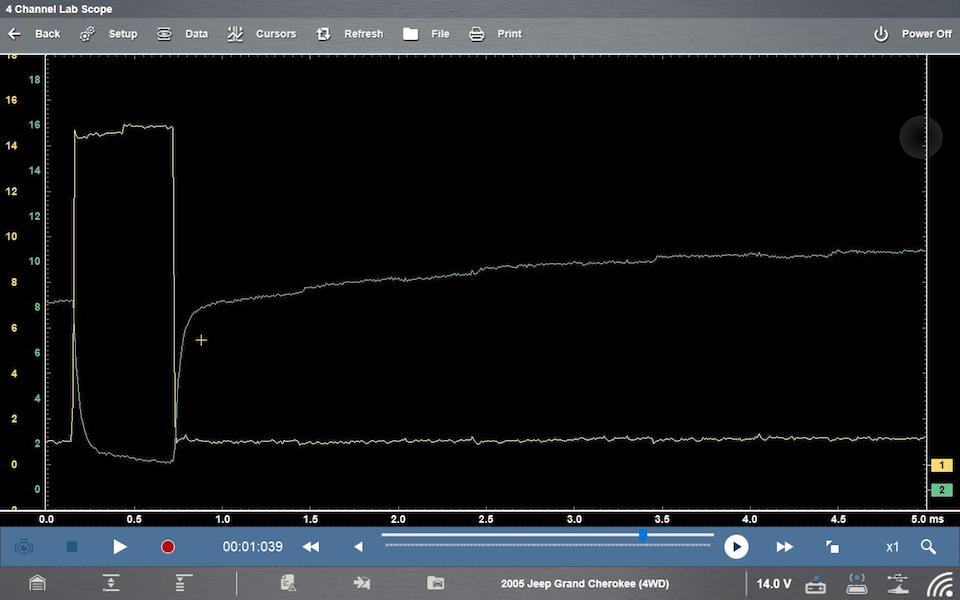

The Jeep would intermittently set a P0750 code when hot, so we started the diagnosis. We started with a battery and charging system test, checked fluids, visual inspection, etc. We hooked a DVOM up to the L-R solenoid at the case connector, and it ohm checked OK. We weren’t expecting to find an issue there, but we had to start from scratch. We cleared the code and went out for a road-test. After driving for quite a while, the P0750 code was set again as a “pending code.” After the first time the code set, the transmission went into failsafe mode (see Figure 1).

We went back to the shop to dig a little deeper into this issue. This is where the process can be used on any application where a computer-controlled load (solenoid, in this case) is in play, whether it be a duty-cycle or just an on/off type solenoid. I am not saying this is the only way to do it, but I have found it quicker to find an intermittent issue like this.

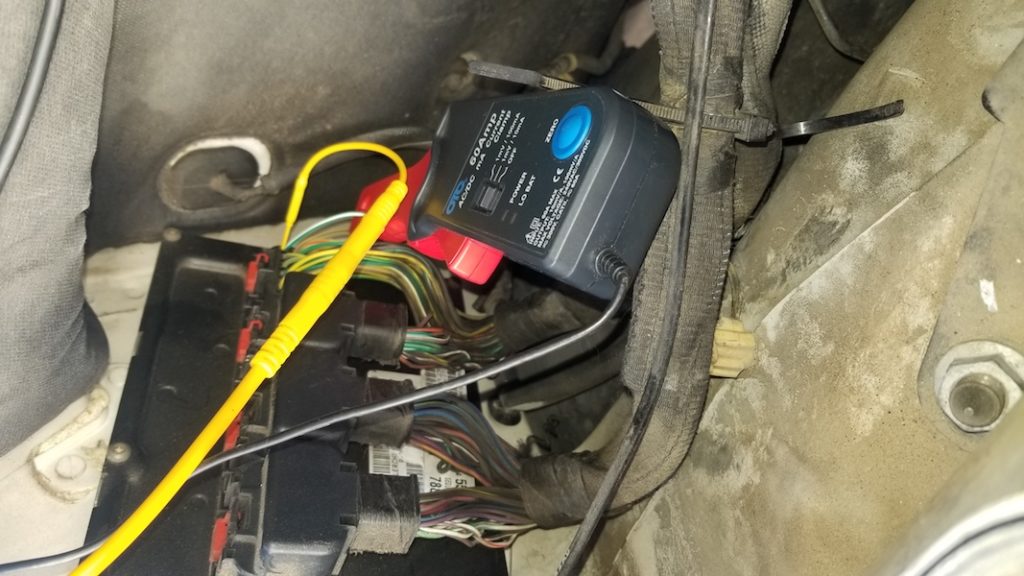

I back-probed into the L-R solenoid circuit at the PCM and connected that to channel 1. Then I attached a current clamp further up the circuit and assigned it to channel 2. This would allow me to look at both the voltage at the control side of the circuit and the amperage simultaneously (Figure 2).

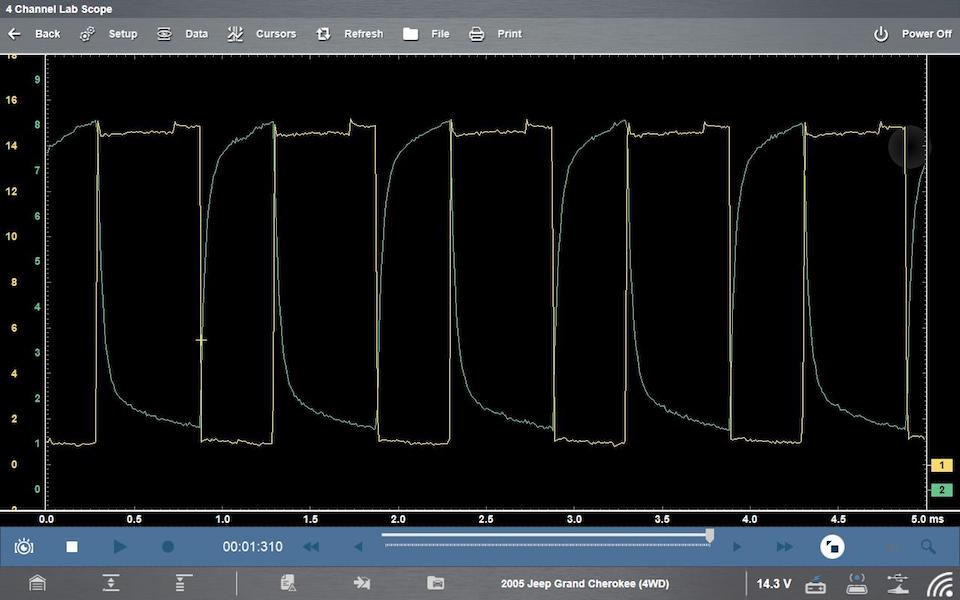

When everything is working correctly, it will look like this on the scope (Figure 3).

We were off for another road-test with everything connected and the wires routed safely to avoid rubbing or pinching anywhere. Just like the first time, it took some time for the code to go active again. I did have someone assist for the second road-test as the stop button on the scope needs to be activated close to the event so you can save the recorded data as the problem happened, so we saved a couple of recordings and headed back to the shop to review them. I was confident I was able to capture the data that showed the problem.

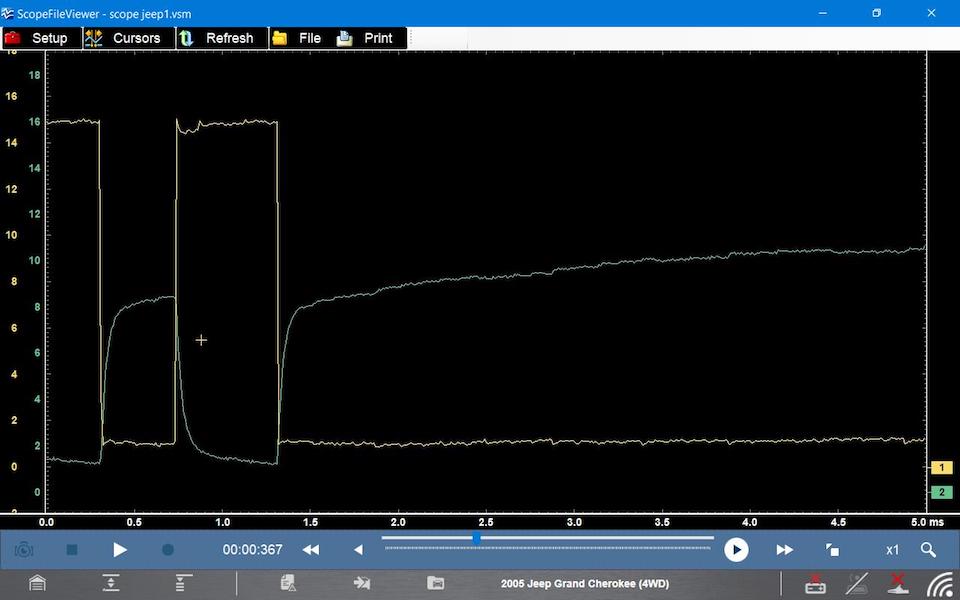

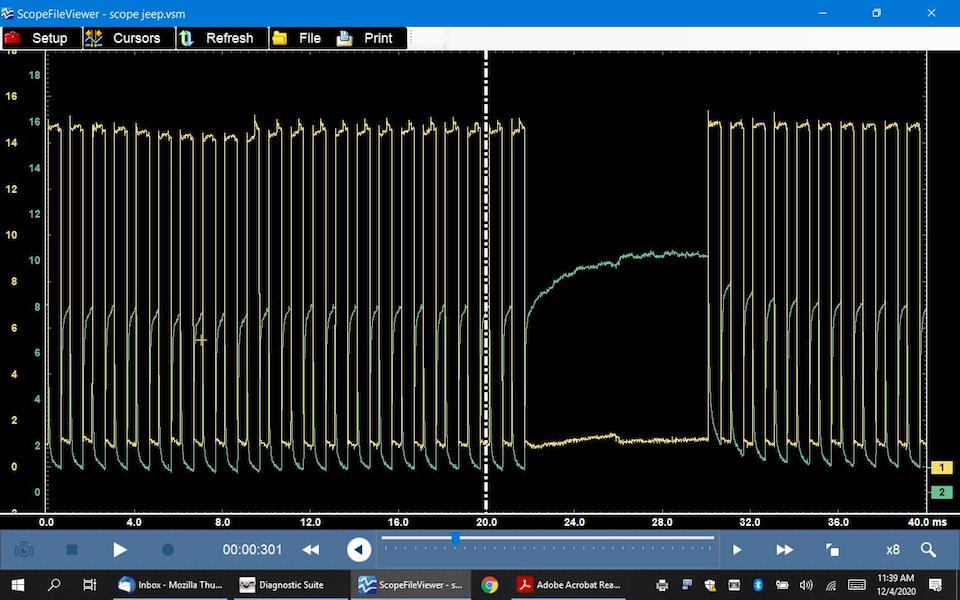

The following images show the first and second time the problem occurred, and without zooming in, you can see the entire event. However, in this circumstance, the fault happened three times before it set the code. (Figure 4 and Figure 5).

I am not an internal computer component expert, so I will probably not speculate what happened inside the PCM to cause this, and I will not fix the controller. I am just going to replace it. I will hypothesize that it looks like the driver inside the PCM stuck on somehow and pulled the circuit to ground; this “event” lasted 8ms. Here is the zoomed-out view, and the issue starts at approximately 22m: (Figure 6)

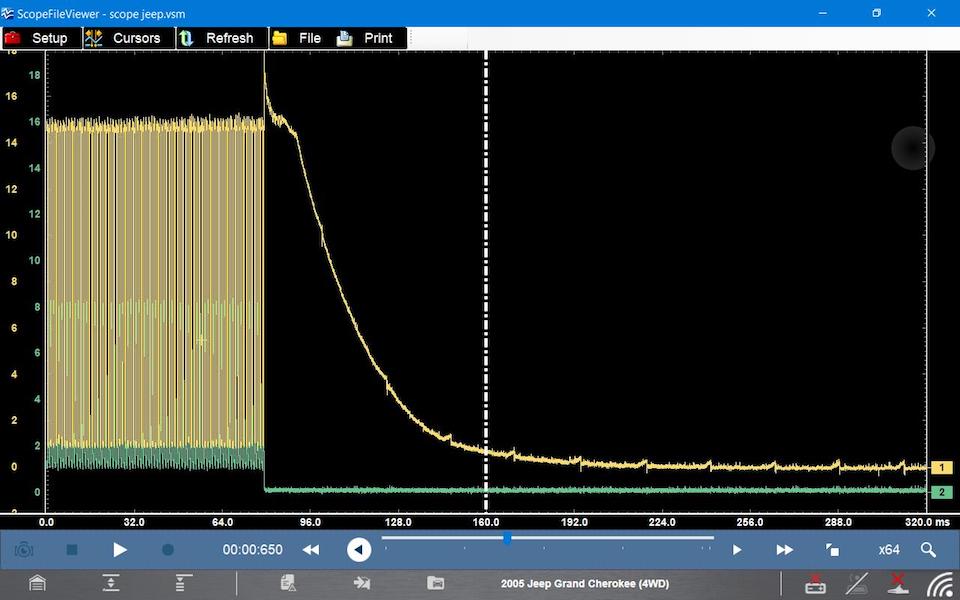

This image shows what the scope looks like when the code goes active. This is zoomed out quite a bit to see the whole event. (Figure 7)

It took 8ms and three separate “events” to set this code. There is no way that a DVOM would capture this issue; I’m sure you could guess or throw some diagnostic darts, and eventually, you will hit your target. Heck, the first shop’s second guess would have been correct!

This method is not the only way to find a bad circuit, ground, load device, or ECU. If you are starting out using a scope, you don’t necessarily need experience to spot a problem. It certainly helps, but you will have a good scope pattern to look at and compare most of the time. In this case, the unit sets an L-R solenoid code. All you have to do to find what “normal” looks like is move your connections to another solenoid that is NOT setting a code. Now you have a perfect example of a good scope pattern to use as a comparison against your suspect solenoid circuit.

In conclusion, most shops have equipment with features that some techs might not use due to perceived complexity. These features can be huge time-savers that equate to more profit and better “first-time-fixed” service for your customers. I strongly recommend that you review what you have and learn how to use these tools.