Up to Standards

- Subject: Repair procedures

- Units: New Venture 261 & 263 transfer cases

- Essential Reading: Rebuilder, Diagnostician, R & R

- Author: Mike Weinberg, Rockland Standard Gear, Contributing Editor

For the 1999 model year, GM introduced the new Chevrolet Silverado and GMC Sierra models of pickup trucks. As part of the upgrade of these models, New Venture Gear designed a new series of transfer cases, the NV 261 and 263. These transfer cases are basically a heavier-duty version of the NV 241 transfer cases used before 1999.

From 1999 to present we find the 261 and 263 units, with the 261 being manually shifted and the 263 being activated electronically from a dashboard switch. The 263 uses an electric encoder motor to move the shift rails internally to the desired mode and range. These are not “active” transfer cases but are part-time units that respond to gear selection at the driver’s command.

The shift positions are 4 Low, Neutral, 2WD High and 4WD High in all models. This means that you cannot operate these vehicles in the 4WD range on hard pavement without binding up the unit internally. All 4WD ranges should be used only in snow, ice or off-road conditions.

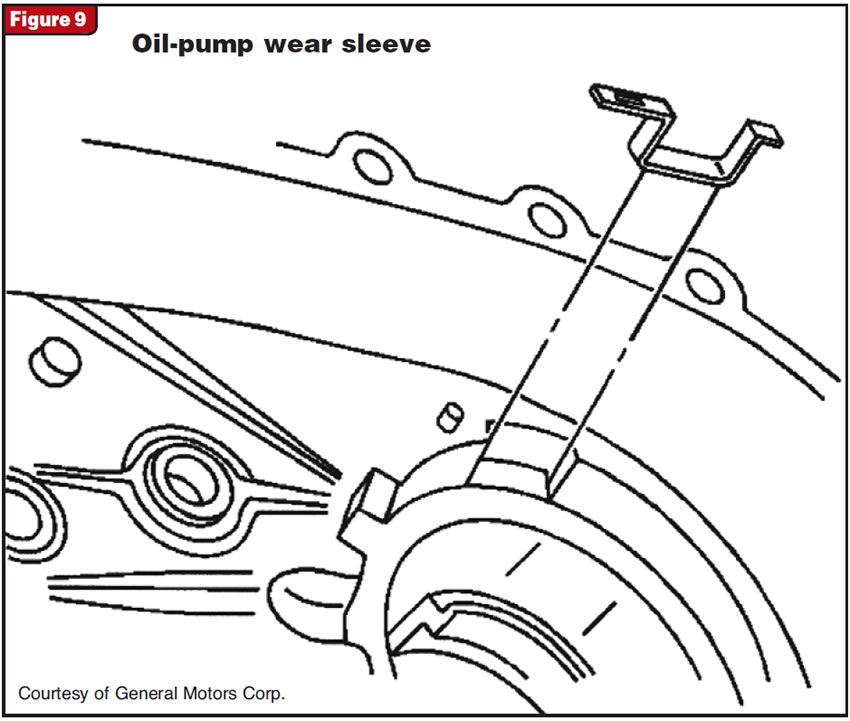

The unit’s dry weight is 77 pounds. It uses a dual-cone synchronizer (see Figure 1) to engage the chain drive for smoother shifting. The low reduction ratio in all models is 2.72-1 for off-road use.

Identification of the units can be a little confusing because of the three versions of the trucks – the 1500, 2500 and 3500 series, which reflect the GVW capacity of the vehicle. The 261/263-series transfer cases have four designations depending on vehicle weight. The 261 comes in an LD model (light-duty) in the 1500-series trucks, and the transfer case has a 27-spline input shaft and a 32-spline output shaft, a 3/8-inch chain pitch, a 11/4-inch drive chain and a four-pinion planetary. There are no 263 models in the 1500 truck series.

Both the 261 and 263 are available in the 2500-series trucks, and both have 32-spline input shafts and 32-spline output shaft. The units found in the 2500 series have a 3/8-inch chain pitch, a 11/2-inch-wide chain and six-pinion planetary and are designated as 261 or 263 HD (heavy duty).

In the 3500-series trucks the 261 is designated 261SHD (super heavy duty) and the 263 is designated 263XHD (extreme heavy duty). These units have 29-spline input shafts and 31-spline output shafts for use with Allison automatic transmissions. The 263 SHD and XHD units have 7/16-inch chain pitches, a 11/2-inch chain width and a six-pinion planet.

The case halves on all models are made from magnesium, which is lighter and stiffer than aluminum. Magnesium has some properties that need careful attention. First, magnesium is flammable. Do not use a welding torch on the cases. If you need to try to loosen a bolt use a flameless heat gun. You can start magnesium burning with a welding torch, and if it should ignite you will think that the sun just moved under the vehicle. The second problem with ignited magnesium is that you cannot put it out with water, as it will separate the oxygen and hydrogen and create an explosion.

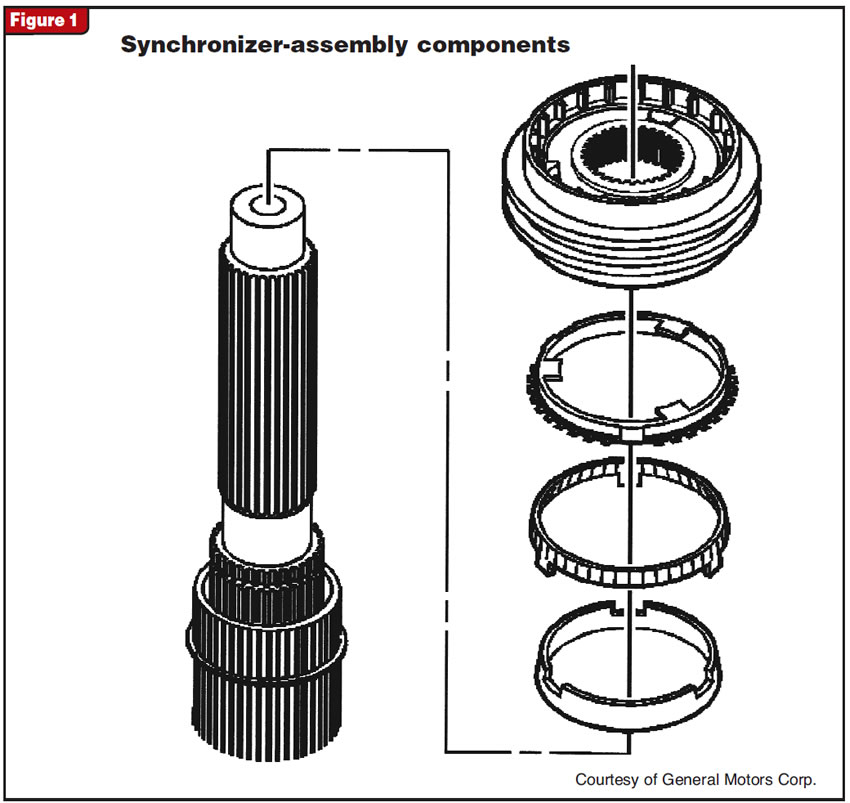

Another problem with magnesium is “galvanic corrosion,” which is the scientific name for the migration of atoms between two dissimilar metals (steel and magnesium). The bolts that fasten the case halves together are steel and come from the factory with cup-shaped aluminum washers to keep the bolt heads off the case (see Figure 2). If you lose a bolt do not replace it with a plain steel bolt or there will be extreme corrosion of the cases. The fill and drain plugs on these transfer cases are made of aluminum and should not be replaced with steel or brass plugs for the same reason. All the external seals for these units should have rubber coating on the outer flanges that butt up to the cases.

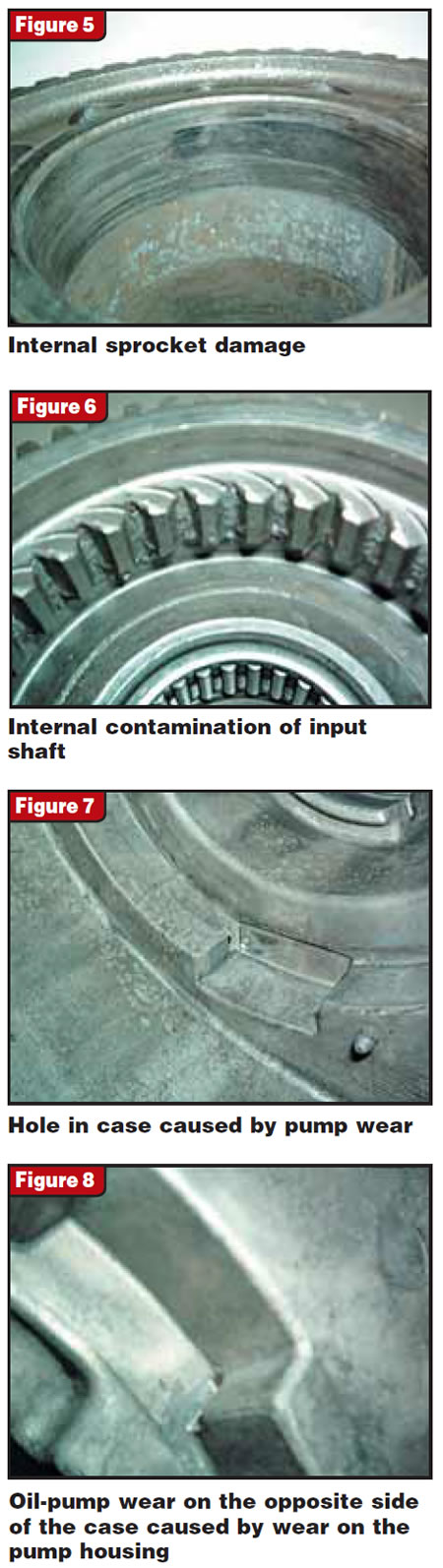

These units suffer from lube-related internal problems. The specified fill from the factory is ATF. These units run hot, particularly behind the Allison units. We are not sure at this point whether the magnesium transfers heat better than aluminum and acts as a “heat sink,” but these transfer cases run hot enough to cause the ATF to vaporize and leave the transfer case through the vent, causing various lube-related failures to the low-range fork and range sleeve, and the drive sprocket to the main shaft (see figures 3 through 8).

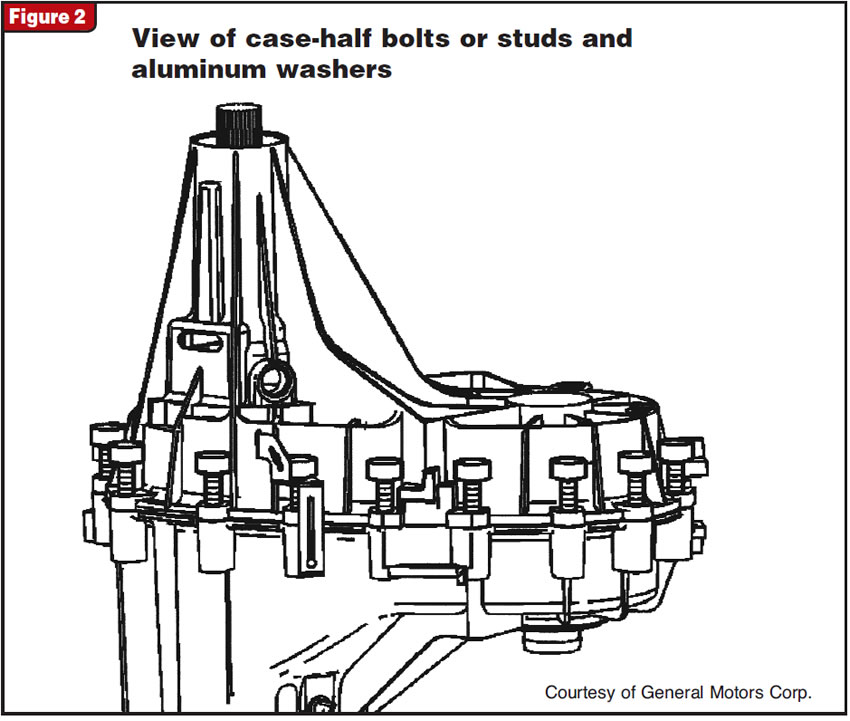

These units are equipped with a gerotor-type oil pump driven off the mainshaft to provide pressurized lube to the internal components. Substitute 5W30 motor oil for the ATF when filling the transfer case and add an extra quart of oil through the speed-sensor opening at the rear of the case. It would be smart to advise the customer to have the transfer-case oil checked every 5,000 miles and changed every 10,000 miles. Every one of these units that we see has either low or no lube and the oil is burned black. We are researching the oil problem further, and when we come up with a more-refined solution we will bring it to you in a future edition of the magazine.

The second common problem is wear to the case caused by the movement of the oil-pump housing. Included in the design is a small steel wear plate on a cast-in peg in the rear case half (see Figure 3). The wear plate usually migrates from its intended position during use, and the oil pump beats a notch into the case. When you are rebuilding one of these units, coat the back of the wear plate with RTV silicone to ensure that it does not move. If you have a unit with this type of case wear, you will need to replace the case half and the oil pump. When the oil pump can travel because of the wear in the case, the oil-pump housing will damage itself on the other lugs that locate it in the case and will need replacement. Carefully inspect the oil pickup filter, pickup tube and O-ring to make sure they are not blocked with debris or leaking.

The NV261/263 transfer cases are relatively simple units to rebuild and service. Every design has some flaws; by correcting them we earn our paychecks and the confidence of our customers. If you pay attention to the details the big items take care of themselves.