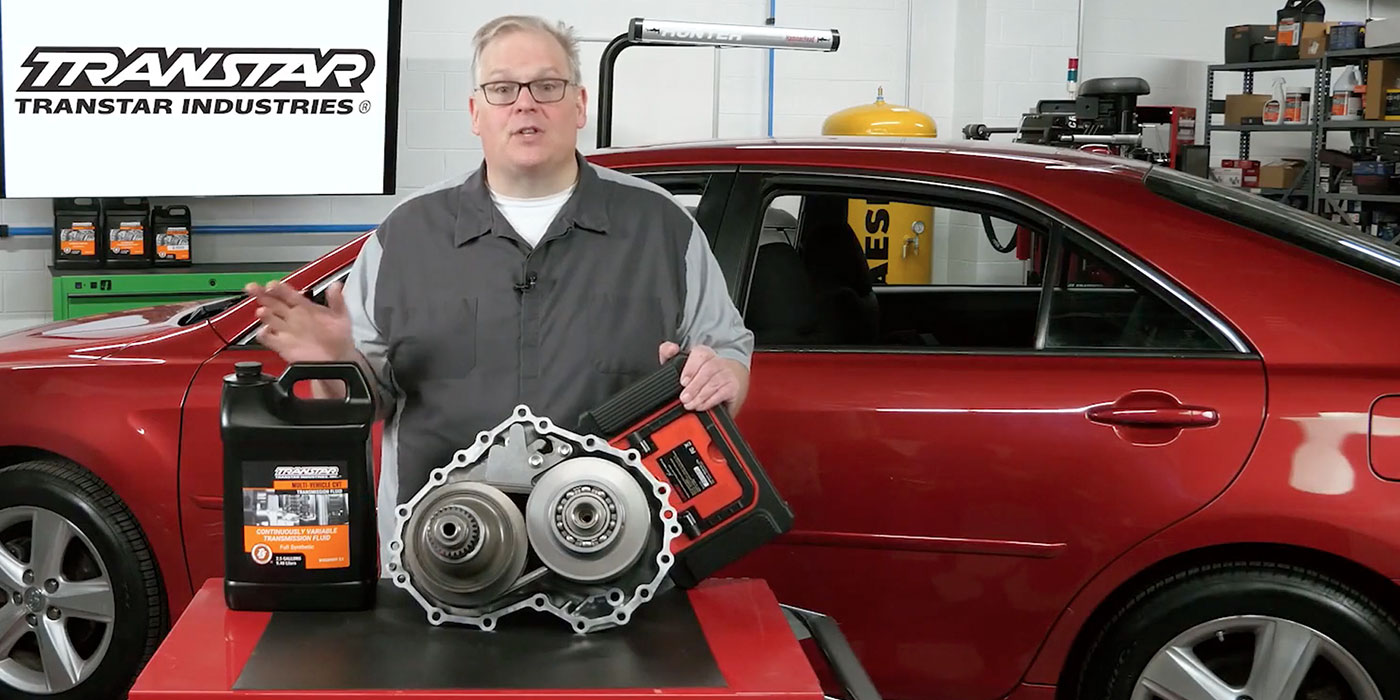

Over the last decade and a half, the industry has become very familiar with the Nissan/Jatco CVT. The market has been flooded with these affordable commuter and passenger cars providing impressive fuel economy. It is partly achieved through the efficiency of these transmissions, but they also have become known for failing within 100,000 miles.

These CVT units, aside from their known issues, are notoriously expensive and difficult to repair. Some of these units cost upwards of $6000 OEM. All of this leads to many customers seeking a used transmission to save some money on the repair.

Here enters the RE0F10D, or more broadly, the CVT8 family of transmissions such as the RE0F10D, RE0F10E, RE0F10H, and RE0F10J. The units are in the Altima 2013+, Rogue 2014+, Juke 2015+, Murano 2015+, Pathfinder 2015+, Maxima 2016+, Quest 2015+, and NV200 2015+. These transmissions cannot be directly installed as a used unit because calibration is required.

New CVT8 transmissions and valve bodies come with a calibration CD from Nissan. This programming accounts for and adjusts the slight variations in output when each valve body is tested in the factory (much like Ford has solenoid strategies and GM has PUN and TUN). When a new valve body is installed, the TCM sometimes will not recognize the latest hardware and sets DTC P17F0 (CVT Judder) or P17F1 (also CVT Judder). You CANNOT clear these codes.

Previously, the only solution to this was installing a new OEM unit with the calibration CD from Nissan, buying and installing a new valve body with the calibration CD from Nissan, or having the dealer order a new calibration CD.

If the customer wants a used unit, it negates any savings when buying a new valve body costs more than the alternative. Nissan has now developed a solution to acquire this programming without removing the valve body or taking it to the dealer for new programming.

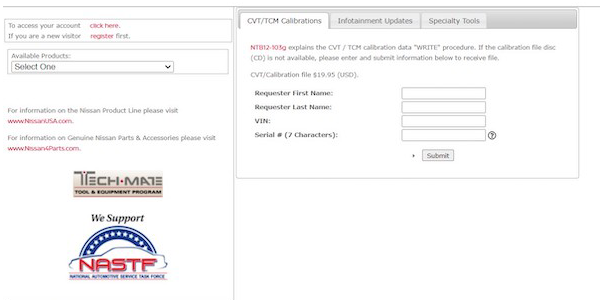

Nissan has now given us the ability to generate the data that would come on that new CD through their www.nissan-techinfo.com. If you have access to a Nissan Consult III+, this saves you the headache and cost of towing the vehicle to a dealer and then waiting for a new disc to be shipped. This will also protect you from misplacing or breaking the OEM CD.

Under “Service Items” on the main page, the website will walk you through requesting a new file for the low price of $19.95. (The little question mark next to the serial number box brings up a PDF file showing the locations where you can find that number). See Figure 1.

Nissan Technical Bulletin NTB12-103f Also shows complete instructions for this procedure.

Once you have entered your name, VIN and serial number (found on the range sensor, transmission case, and valve body), you can purchase and download the new file and rewrite the transmission characterization to communicate with the TCM and ensure the proper function of the transmission. A QR-code sticker is located on the range sensor (see Figure 2).

The next step of this process is required whenever the transmission or valve body is replaced; Certified Transmission supplies the CD when a remanufactured CVT unit is purchased from us.

Load the new IP characterization file onto a jump drive or external drive and connect to the Consult III+. Navigate to “Transmission” under “Diagnosis (One System)” and select “Work Support.” From there, select “Write IP CHARA- Replacement AT/CVT” and copy the data shown. Then start the procedure and select the IP characteristics file that you got from Nissan.

Double-check that your serial number matches the numbers you entered to generate the file and select next. It will prompt you to follow a calibration reset procedure. Ensure you have the ignition on and the engine off, hold the brake and put the shifter into reverse, then depress the throttle about ¼ to ½ while still holding the brake, and while maintaining this, hit start.

Once that is complete, it will prompt you to cycle the ignition off for two seconds. Now you can be put the transmission back in Park, and you are ready to rewrite the calibration. Once this is complete, it is vital to perform ten garage shifts to ensure proper adaptation.

Now the vehicle is ready for the final test drive and can then be returned to the customer. If this is confusing or hard to track, refer to the bulletin mentioned above for specific instructions. The prompts on the Consult III+ are self-explanatory.

It may seem like a lot of work to go through, but the process only takes about 30-45 minutes. It also saves time on towing the vehicle to the dealer, paying the dealer to reprogram it, and the time/tow to get the vehicle back. All this means savings for your customer and a quicker turnaround.

Adding this skill to your repertoire gives you more confidence in your understanding and abilities with this relatively new technology. It makes the job a little more profitable and keeps the work in your shop. It’s a better experience for the customer and reassures them that they made the right choice in selecting YOUR shop to do the job.

As a side note, you do not need to have the full-blown Consult III+ to do this procedure. Certified Transmission has tested the Consult III+ RTR (Right to Repair) software and found that this process works like regular Consult III+. There is a lack of information about what the RTR software can or can’t do. We have been told that the “Diagnostics” portion was only functional in 2018-up models. We found this claim to be only partially true.

At the same time, some of the functions do not work (e.g., Diagnosis ALL Systems). You can still go into individual modules and get codes, data, and work support, which we commonly call functional tests or system tests. Better yet, if you do not typically see Nissans in your shop, the Consult III+RTR subscription is available on-demand for only $30 per day.

This capability is available on any Windows 10 laptop combined with a J2534 device (Nissan recommends Drew Tech Cardaq+3). Just more tools and knowledge to help you take care of your customers.

Zack has four years of automotive industry career experience and has spent a few years as an automatic transmission specialist. He is currently a Diagnostician for Certified Transmission at our Grandview, MO facility.