Torque Converter Tech

- Author: Joe Rivera

Today’s torque-converter rebuilders face increasingly complex rebuilding jobs. Perhaps no other torque converter has put rebuilders to the test more than some of the ZF 5HP-style converters. These torque converters are manufactured with what is described as a “captive clutch” and would normally be considered a non-serviceable item.

However, just like the crafty raccoon that always finds a way into your garbage regardless of the obstacles you place in front of him, ever-resourceful torque-converter rebuilders have found a way in and out of this torque converter.

If you haven’t seen one of these in your shop yet, you will. They’re already in BMWs, Audis, Jaguars, VWs, Land Rovers and Porsches and are becoming more common. So sooner or later you’re going to run into a ZF 5HP torque converter with a “captive clutch,” and when you do you’d better be prepared to deal with it.

What is this elusive “captive clutch?” The best way to describe it to a transmission rebuilder is like this: Imagine removing a transmission from the vehicle, disassembling it and then, when you go to open the clutch packs, discovering that they are welded shut!

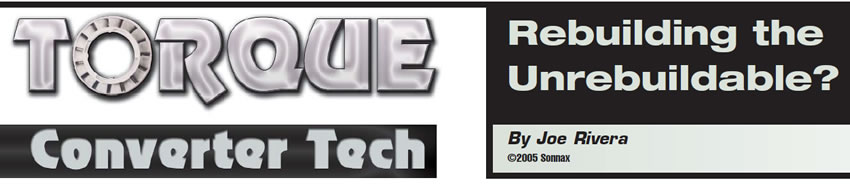

That’s what torque-converter builders are up against in some of these 5HP converters (see application list at end of article). There are several types of these torque converters out there. There is the earlier crimped-style clutch (see Figure 1), and then there is the friction-welded clutch (see Figure 2) and as of late there are reports of an actual welded clutch (see Figure 3).

The big question is, how should the clutch be opened up and repaired? The quick answer is, not easily. But it is not impossible. Some rebuilders have opted not to rebuild them because of the complexity and the potential for warranty issues. Also note that many of these units are available directly from ZF new or factory remanufactured through suppliers. Regardless of which direction you choose in repairing the vehicle, the point of this article is to describe what we are up against in the aftermarket.

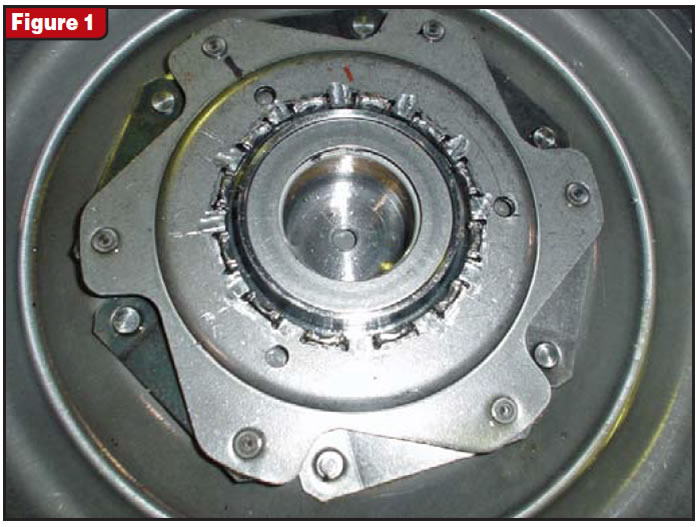

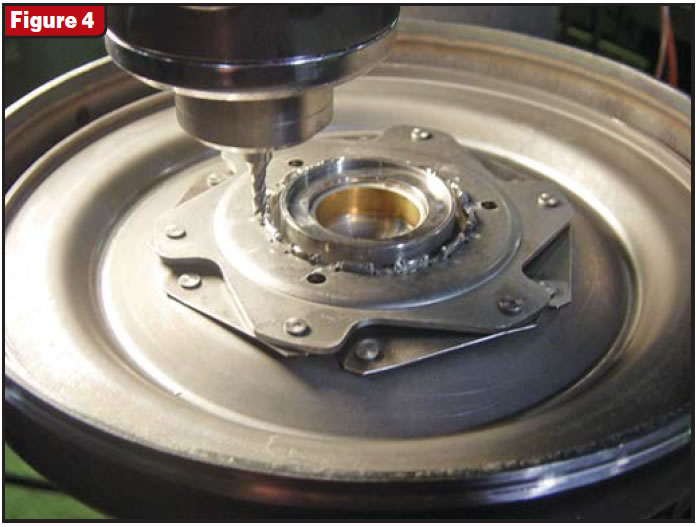

Which style of clutch you have determines how you will have to attack it. If it is the crimped style, what I might recommend is that you make some tools to remove the crimped part very carefully on a milling machine (see Figure 4). From there you can carefully disassemble the parts for inspection and repair (see figures 5 and 6). The key to the next process is to remember that the clutch itself is preloaded and will have to be assembled under a load to reset the spring-loaded clutch (see Figure 7).

This is a lot more difficult when the unit has a friction-welded clutch assembly. If you don’t machine the clutch open at the exact right diameter, you have destroyed the core (see Figure 8). The piston’s inside diameter is about 2.950 inches, and this must not be damaged. Keep in mind there is an O-ring right underneath there (see Figure 9), and when you reassemble that clutch and weld it shut, you must remember that O-ring. Also bear in mind that you will have to make some type of tool (see Figure 10) and set it in a fixture to make sure the clutch gets the correct spring load. If you don’t set the clutch preload correctly, you won’t get lockup.

Take your time welding the clutch up. This is an important step, because if you go too fast you will ruin the spring and the TC won’t lock up. Use small tack welds and allow for the weld to cool in between.

Yes, these captive clutches are not for the faint of heart, but they do challenge the ingenuity of torque-converter rebuilders.

Note: Not all ZF 5HP units are using this “captive clutch.” The ZF 5HP18 converters are very similar to the ZF 4HP22/24 units; they all seem to be single disc. And the ZF 5HP30 is a larger torque converter and has a snap ring that holds the clutch assembly together.

Here is a current list of models with the “captive clutch”:

- ZF 5HP19

- ZF 5HP19FL

- ZF 5HP19FLA

- ZF 5HP24

- ZF 5HP24A

Joe Rivera is the owner of ProTorque and a member of the board of directors of the Torque Converter Rebuilders Association, a professional not-for-profit organization formed for the betterment of the converter-rebuilding industry. This and related information are available to TCRA members at www.tcraonline.com.