We all have those family members and loved ones who need our help and expertise when it comes to cars, and I am no exception. I purchased a 2001 Honda CRV AWD with a possibly bad transmission for my daughter to replace the worn-out vehicle she was driving. After determining that the transmission was indeed on its way to failure, I ordered a remanufactured unit to replace it. Except for the usual oil leaks these vehicles have, this CRV had low miles and was in really good shape for its age. I felt that it was a good candidate for investing my time and money.

After receiving the new transmission, I removed the old unit, repaired the oil leaks on the engine, and installed the remanufactured unit. After filling the transmission and checking things over it was time to perform the final road test to make sure it was working as it should. The transmission operated as it was designed to. All was well with a happy ending. Or so I thought…

Read more stories in our R&R Tech series here.

As you can imagine, my daughter was very excited to pick up her new-to-her ride. As she drove away, I was crossing my fingers that the only immediate contact from her in the future would be to say hello; and for about two months, that’s exactly the way it was. Then one evening as she was leaving work the check engine light came on. As she explained it, “The car won’t go very well.” How many of you have heard that one? So being a dad, off to the rescue I go. I found her in the parking lot and confirmed what she explained to me over the phone. The check engine light was on, and the ‘D’ indicator was flashing. Well, it was too late in the day to do anything, so I sent her off in her mother’s car.

The next morning, I had the CRV towed into work so I could diagnose the issue. When it arrived, I drove it into the bay, and it felt like it was stuck in second gear. I connected a scan tool and ran it for codes and found several stored in memory: P0135 (Primary Heated Oxygen Sensor), P0500 (Vehicle Speed Sensor) and a couple of evaporative emission codes. I cleared the codes, but they returned immediately. This led me to believe there might be a circuit issue of some sort. I wanted to investigate the manufacturer’s definition of the stored codes, so I sat down at the computer to do some research.

I cannot say enough about ongoing training in this industry. Along with online webinars once a year, here in Kansas City we have a training seminar called “VisionKC.” This is a valuable source of training and information that can make our tough jobs a little easier. One of the instructors taught us to sit down and research the codes with wiring diagrams and power distribution charts to trace what systems and devices are associated with the problem the vehicle is having. I was already doing this, but not in the way he taught us in this class. This technique narrows down the problem area in which to look. It can speed up the process of finding the problems causing the issue with the car.

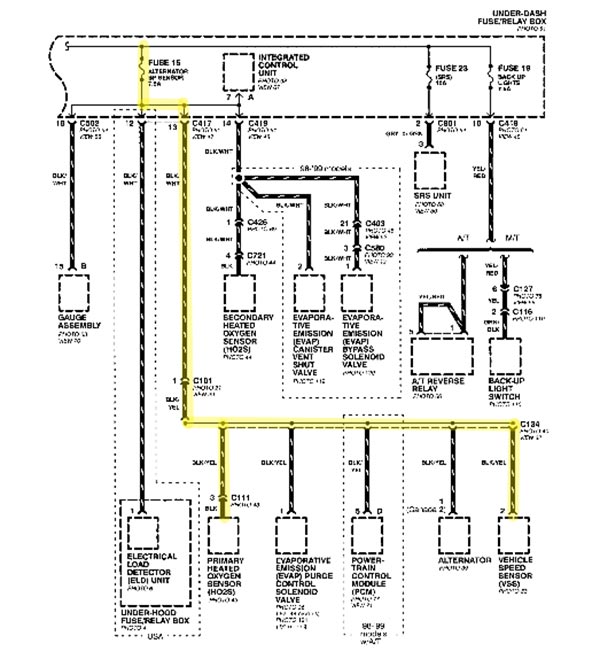

From the wiring diagrams I viewed, I discovered that all the codes were related by being powered by the same 7.5-amp #15 fuse in the under-dash fuse box (as seen in Figure 1).

I was amazed to see how many devices were powered by one low amperage fuse. The fuse was open, so I replaced it and it blew again as soon the key was turned to the run position. This was a clear indication of a short to ground somewhere before the load. Since there was a P0500 code, I decided to go down this road first. A quick check of the vehicle speed sensor and circuits showed nothing to be wrong in that area, so it was on to the next area of concern.

The next circuit of concern was for the oxygen sensor due to the P0135 code. After raising the CRV on the rack, I started by giving the O2 sensor the once-over. I didn’t see it at first, but on the second look I noticed the O2 sensor pigtail had fallen out of the holding bracket. The wires had been rubbing on the passenger side axle half shaft for a while, causing the heater circuit wire of the O2 sensor pigtail to wear through. (See Figure 2).

This, in turn, caused the short to ground that blew the 7.5-amp fuse. With the wires repaired and the pigtail secured back in the holding bracket, I also used a long-trusted device called a “zip-tie” for added security.

After lowering the vehicle down, replacing the fuse and clearing the codes, it was time to see if everything was operating as it should. As the old A-Team leader once said, “I love it when a plan comes together.” The CRV was shifting properly again, and the lights were staying off, which meant Momma got her car back.

The moral of this story is that training and having a game plan can help speed up repairs. Sometimes we get lucky and see problems right away, but if you’ve been doing this a while, you know that’s not always the case. The newer the car, the more important it is to research and have a plan of action. That little extra time spent to research saves you tenfold in total diagnostic time.

Carman Klaber is a diagnostician with Certified Transmission. Carman has been in the transmission industry his entire career and has been with Certified Transmission since 2003. He has held ASE certifications for over 25 years. He is married with two children and enjoys camping and riding ATVs.