TASC Force Tips

- Author: Ed Lee

- Subject Matter: 722.6 unit & engine with MDS system

- Issues: Downshift shudder, cold-stall condition

A 2007 Dodge Charger equipped with a 5.7L V8 engine and 722.6 transmission was brought to a transmission shop. At the time of the visit, the vehicle had more than 88,000 miles on the odometer. The customer told the service writer that the vehicle had previously been to four different repair shops in a failed attempt to eliminate a downshift shudder and cold-stall condition. A technician road-tested the vehicle and described the condition as a vibration when coming to a stop and — since it was February in the Northeast — the cold-stall condition also was quickly verified.

The shop was very familiar with the coastdown shudder condition. They had fixed dozens of Sprinter vans with the same shudder by adding piston return springs to the TCC piston in the converter. The service writer was fairly confident that adding the return springs to the converter would fix the condition, but opted to sell a rebuilt transmission and torque converter combination because of the vehicle’s high mileage.

The transmission rebuild went routinely. Discovery of a dark wear pattern on the converter clutches reinforced the idea that the clutches had been dragging. When the transmission and converter rebuilds were completed and reinstalled, the vehicle was road-tested. The technician found that the cold-stall condition was no longer present, but the shudder was still there.

A lot of second guessing started at this time. Some research found that the previous four repair shops had focused on engine performance as a possible cause. One shop even had discovered that the condition could be eliminated by placing the shifter into the auto-stick (manual shift) mode. The same shop also discovered that the vehicle was equipped with a multi-cylinder displacement system (MDS).

The MDS system was introduced by Chrysler in 2004 and functions like the Mercedes Benz Active Cylinder Control, General Motors Active Fuel Management and Honda’s Variable Cylinder Management. In short, the MDS system deactivates four of the V8 cylinders during closed throttle operation or at steady speeds – including coastdown – and the system is not active when the shifter is in auto-stick mode. Unfortunately, the shop was not able to complete the repair circle because they got hung up on the fact that the system was functioning properly.

In 2014, ATSG published an excellent bulletin (14-W22) about this condition. Besides explaining how the concern goes away with the shifter in auto-stick mode, the bulletin also relays how the electronic modulated converter clutch strategy (EMCC) is not active in auto-stick mode. This means the condition won’t be felt when the TCC is not locked up. The normal vibrations created by a V8 engine running on four cylinders are transferred by the locked-up torque converter, but are isolated from the passenger compartment by the engine mounts. Over time, the engine mounts sag down to a point that the safety rod contacts the base of the mount, allowing the vibrations to be noticed by the driver. When the mount is together it is difficult to see the problem (Figure 1).

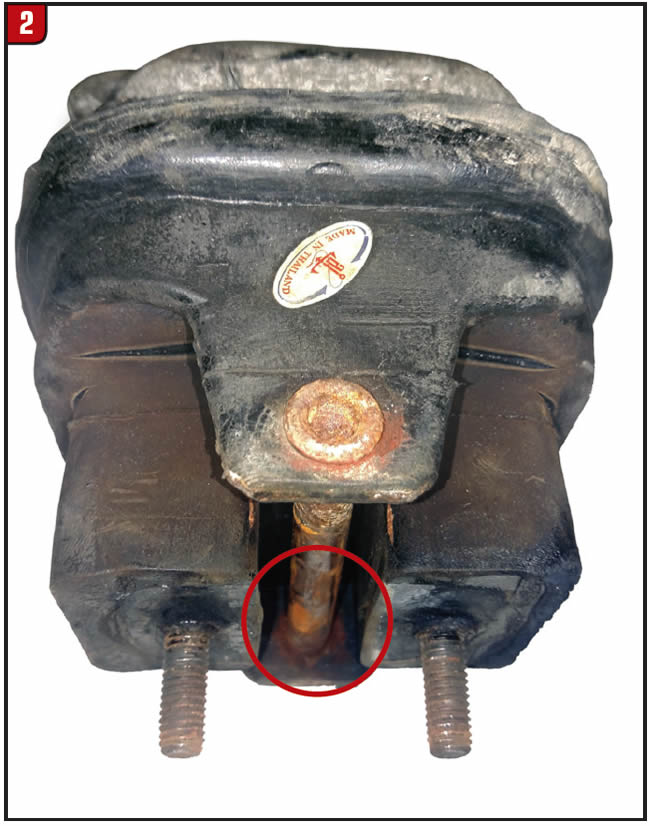

When the mount is in the vehicle, the sag is even more difficult to see. It takes a high intensity light and a mirror to make detection possible. When the mount is separated, you can see witness marks where the safety rod contacted the base plate (Figure 2).

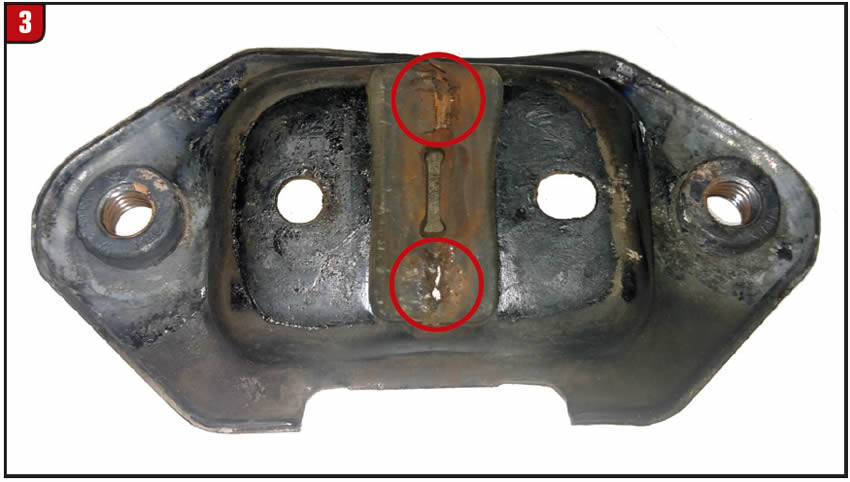

When you look at the base pate of the mount, you can see that the safety rod has damaged the rubber pad (Figure 3).

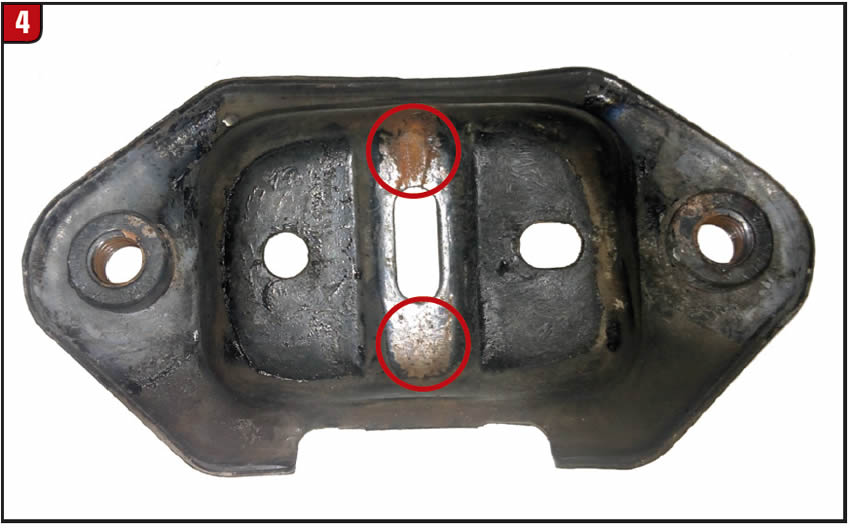

The metal-to-metal contact is exposed when the pad is removed (Figure 4).

When diagnosing a shudder condition on a vehicle equipped with a 722.6 transmission and an engine with a MDS system, always qualify the shudder by placing the shifter into the auto-stick mode. Don’t forget that the mount does not have to be separated or broken to cause the shudder condition.

Ed Lee is a Sonnax technical specialist who writes on issues of interest to torque converter rebuilders and member of the Sonnax TASC Force (Technical Automotive Specialties Committee), a group of recognized industry technical specialists, transmission rebuilders and Sonnax Industries Inc. technicians. Sonnax supports the Torque Converter Rebuilders Association. Learn more about the group at www.tcraonline.com.