TASC Force Tips

- Subject: Preventing throttle-valve-actuator codes

- Unit: 48RE

- Vehicle Applications: Dodge Ram 2500 & 3500 diesel trucks, 2005 up

- Essential Reading: Rebuilder, Diagnostician

- Author: Jeff Parlee

In 2005, Dodge started using a transmission throttle-valve actuator (TTVA) instead of a TV cable on the 48RE diesel 2500 and 3500 Ram trucks. The actuator, attached to the case above the throttle-valve shaft, includes two potentiometers that provide input to the ECM as well as a DC motor that responds to ECM output. The bottom of the TTVA shaft features a D-shaped opening that fits onto the throttle shaft, allowing the actuator to mechanically stoke the TV valve and ultimately control transmission throttle pressure.

There are no adjustments for the TTVA; it must be initialized when replaced or removed and reinstalled on the transmission. Every time the ignition is cycled on, the ECM performs the internal calibration procedure to find the current “zero” position. To initialize the TTVA, the ignition must be held in the “on” position for at least 30 seconds.

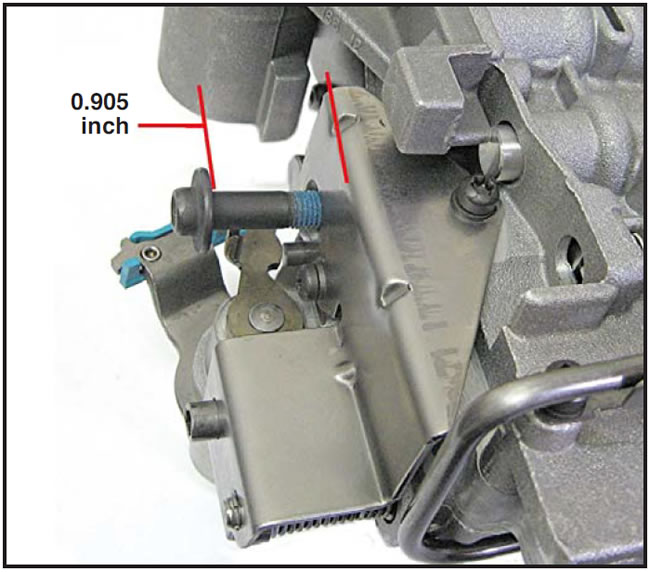

During the calibration procedure, the ECM is looking for at least 48 degrees of movement from minimum to maximum span and to establish a minimum range value. Both of these parameters can be affected by the throttle-shaft adjustment bolt on the pressure-regulator-spring retaining bracket. The distance between the bracket and the inside edge of the adjustment-bolt head should be 0.905 inch. A shorter distance will not allow the TV shaft to travel far enough to satisfy calibration parameters and will set code P1751 and/or P1752.

Here is where you can easily get into trouble. Some of the brackets for cable-activated throttle valves have as little as 0.820 inch between the bracket and the inside of the adjustment-bolt head. Using the cable-type bracket setup in a TTVA-equipped unit without changing the setting on the adjustment bolt can set the same codes.

Transmission Throttle-Valve-Actuator Code List:

- P1749 – Transmission throttle valve position sensor circuit low

- P1750 – Transmission throttle valve position sensor circuit high

- P1751 – Transmission throttle valve position minimum range performance

- P1752 – Transmission throttle valve span performance

- P1753 – Transmission throttle valve mechanical performance

- P1754 – Transmission throttle valve actuator stuck

- P1755 – Transmission throttle valve control circuit

Special thanks to Mike Ware of Transware Transmission in Concord, Ontario, for his help with the research on this article.

Jeff Parlee is director of product support at Valve Body Xpress and a member of the Sonnax TASC Force (Technical Automotive Specialties Committee), a group of recognized industry technical specialists, transmission rebuilders and Sonnax Industries Inc. technicians.

©Sonnax 2010