A Saturn vehicle equipped with the VT25E CVT transmission comes in with a complaint of slipping in all ratios as well as reverse.

The slippage could be caused by inadequate line pressure, worn inner-pulley seals or a slipping drive belt.

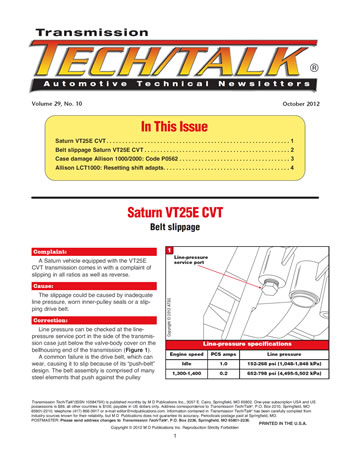

Line pressure can be checked at the line-pressure service port in the side of the transmission case just below the valve-body cover on the bellhousing end of the transmission (Figure 1).

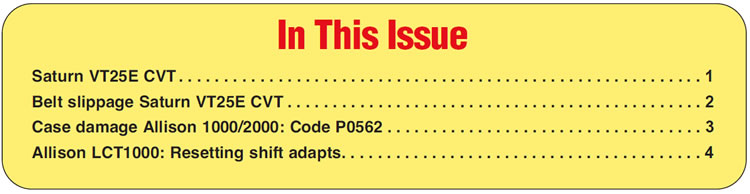

A common failure is the drive belt, which can wear, causing it to slip because of its “push-belt” design. The belt assembly is comprised of many steel elements that push against the pulley sheaves and therefore holds by compression, not by tension (Figure 2). Make certain when installing the drive belt that the arrow on the belt points in the direction of rotation (Figure 2) to avoid premature belt failure.

Warning: Line pressure at heavy throttle can be extremely high, as shown in the chart in Figure 1. Make certain pressure gauges are adequate to handle these pressures and are in good condition.

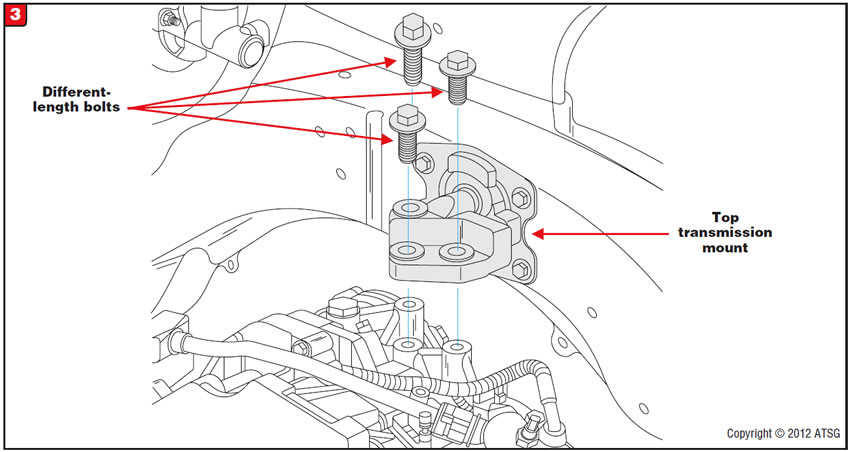

After installation of the transmission, a leak coming from the inside of the bellhousing is discovered. Once the transmission is removed, it is evident that the case is leaking because of breakage in the area of the bolt holes in the top transmission mount.

The bolts that hold the top transmission mount in place are different lengths (Figure 3).

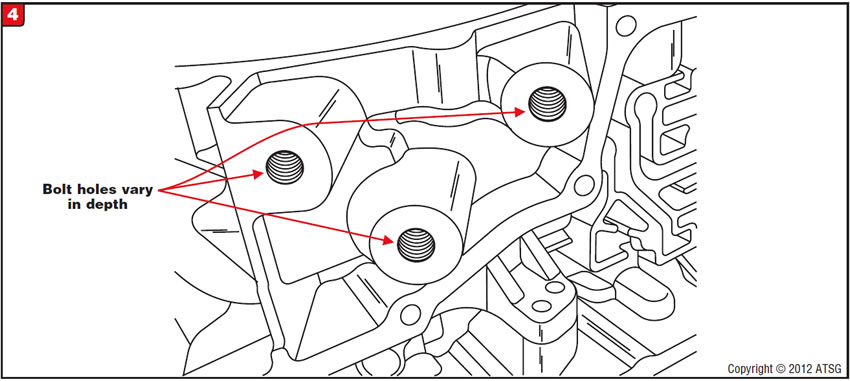

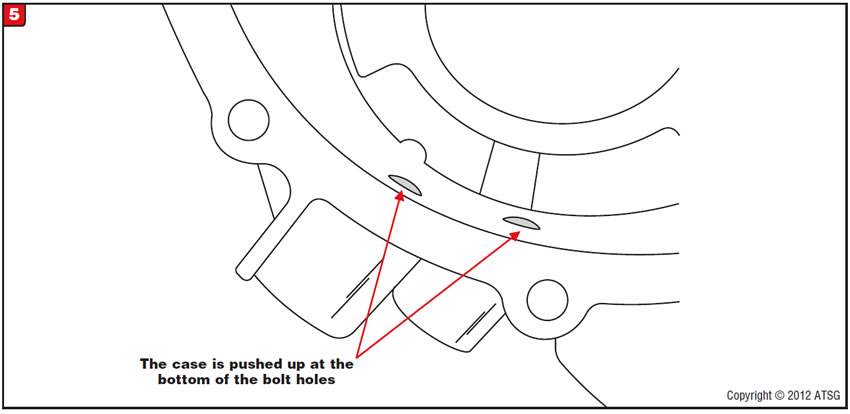

The installer put a long bolt where a short bolt should go (Figure 4);

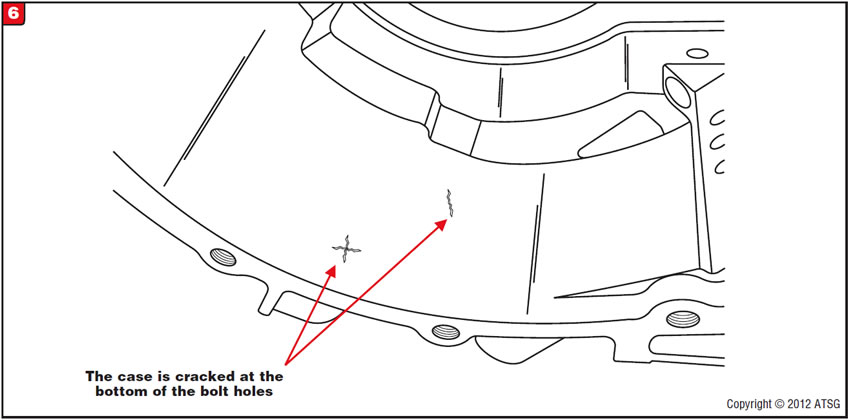

the long bolt bottomed out in the bolt hole and pushed the case out, resulting in the case cracking (figures 5 and 6).

To avoid the need for case replacement, inform all installation staff of this potential damage hazard.

A truck with an Allison 1000/2000-series transmission can come into the shop with any of the following complaints:

- The malfunction indicator lamp is illuminated and the transmission is in failsafe.

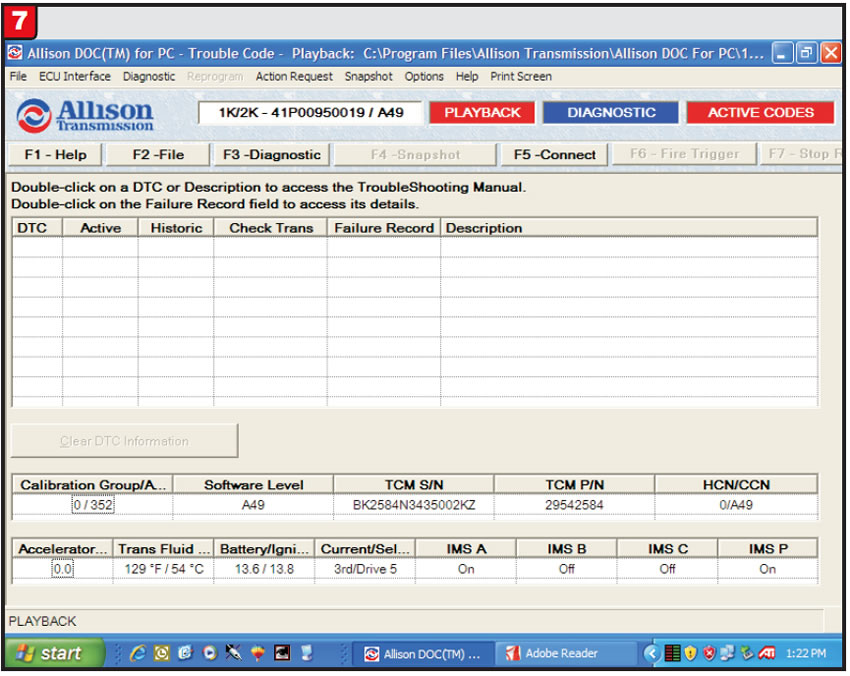

- Codes P0562, P0872 and, on later vehicles, U2106 are stored (Figure 7). In some instances codes P0871, P0841, P0842, P0846 and P0847 also may be stored.

- Harsh or delayed engagements.

A faulty ignition switch or TCM.

Code P0562 indicates system voltage is low; what this really means is that the supply voltage to the TCM is low.

Code U2106 indicates loss of communication with the TCM.

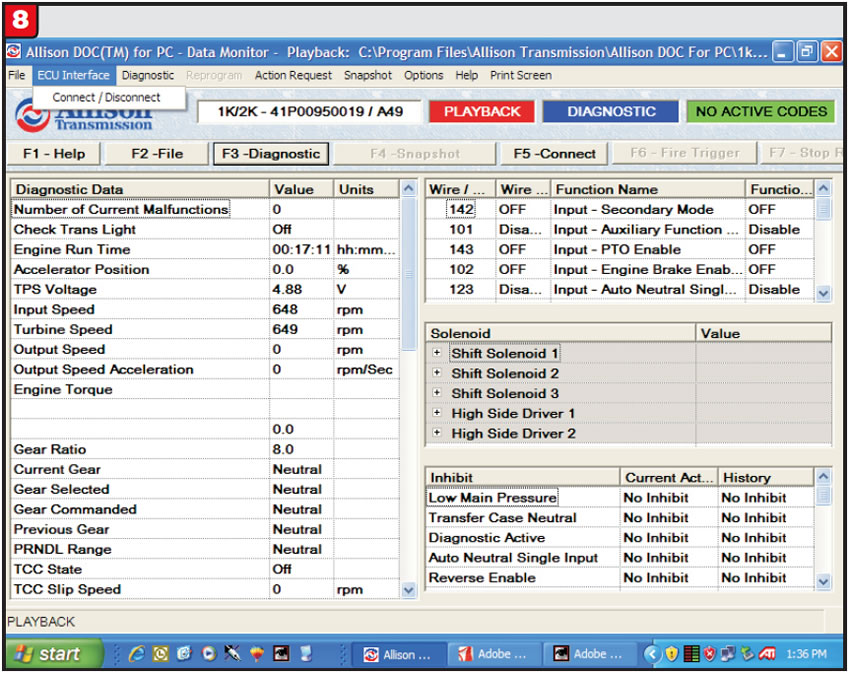

Codes P0871, P0872, P0841, P0842, P0846 and P0847 indicate no change in the pressure switches when a related solenoid was commanded on or off (Figure 8).

Reviewing the scan data shows that the battery voltage is displaying 14.2 volts, yet the ignition voltage is only 5.2 volts. These two parameters should always match; the fact that they don’t indicates a problem with ignition-on voltage supply (Figure 8).

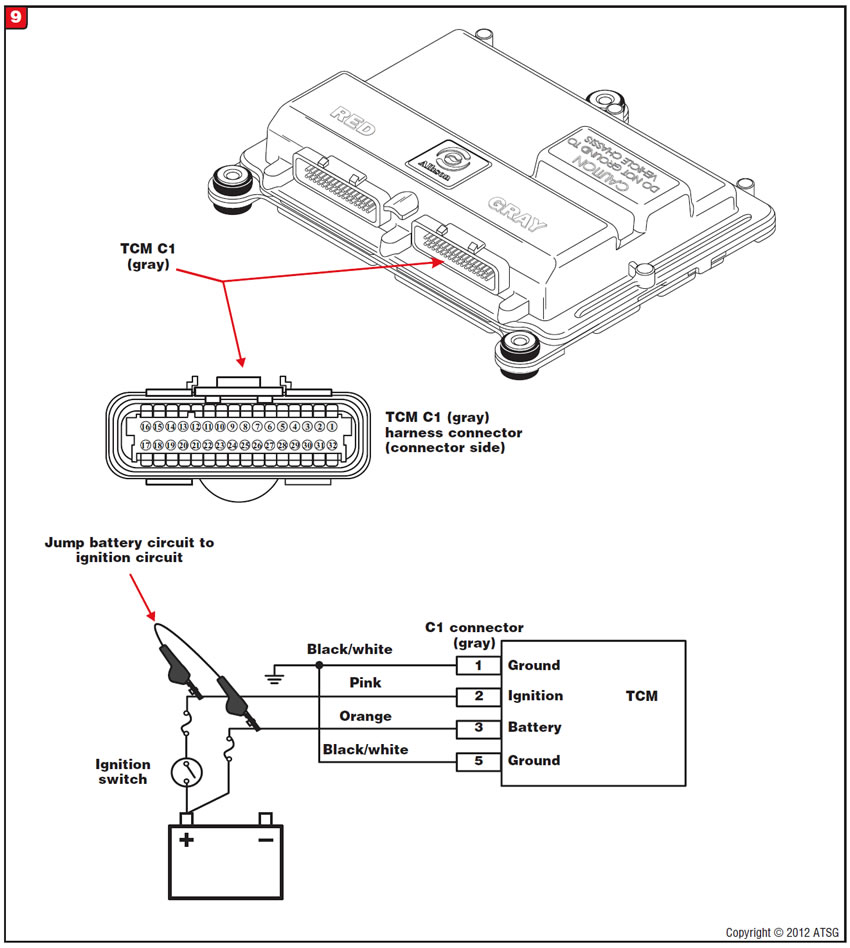

To verify this, connect a jumper lead to the orange wire at TCM connector C1, terminal 3, and also to the pink wire at TCM connector C1, terminal 2 (Figure 9).

If you can clear all the codes and the transmission operates as it should, then the ignition switch is to blame.

If the connection of the jumper lead results in no improvement, the TCM may be faulty.

In some instances this situation may occur only when the vehicle has been at normal operating temperature. Sometimes if the TCM is cooled down the vehicle goes back to normal operation; at this time the TCM is to blame.

If the shop is looking for an alternative repair for the ignition-switch fault, a power-relay harness can be installed to bypass the ignition switch. Unlike with a 4L60-E/4L80-E, where the relay voltage-supply circuit is wired to case-connector terminal E, in Allison applications it will be wired to TCM connector C1, terminal 2.

Note: Some wiring diagrams show a pink power-supply wire at terminal 4 and also spliced to the pink wire at terminal 2. Your vehicle may not have a wire at terminal 4.

After transmission repairs or replacement or TCM replacement the vehicle exhibits shift-quality concerns such as bind-ups, flared shifts or coast-down clunks.

The transmission shift adapts have not been reset.

When any of the repairs or replacements mentioned have been made, the TCM must be informed that the vehicle has been repaired. If it is not informed, the TCM adaptive controls will attempt to shift the rebuilt transmission the same as it did with the damaged transmission. The shift data under these conditions will not match the target shift profiles that were programmed into the TCM. Do not confuse the shift-adapt reset with reflash; they have completely different functions.

Using a capable scan tool, choose from the menu “Reset Shift Adapts.” After you choose, the scan tool will ask whether you want to perform a “Fast Adaptive Relearn.” This mode will cause the TCM to make large changes in initial shift conditions to adjust for major system tolerances such as solenoid-to-solenoid operations, main pressure and clutch-to-clutch variations.

Once the initial reset has been performed, the TCM will enter a “Slow Adaptive Mode,” which will fine-tune shift logic as the vehicle is driven. The TCM has the ability to switch back and forth between fast and slow modes when necessary to compensate for shift-profile changes.

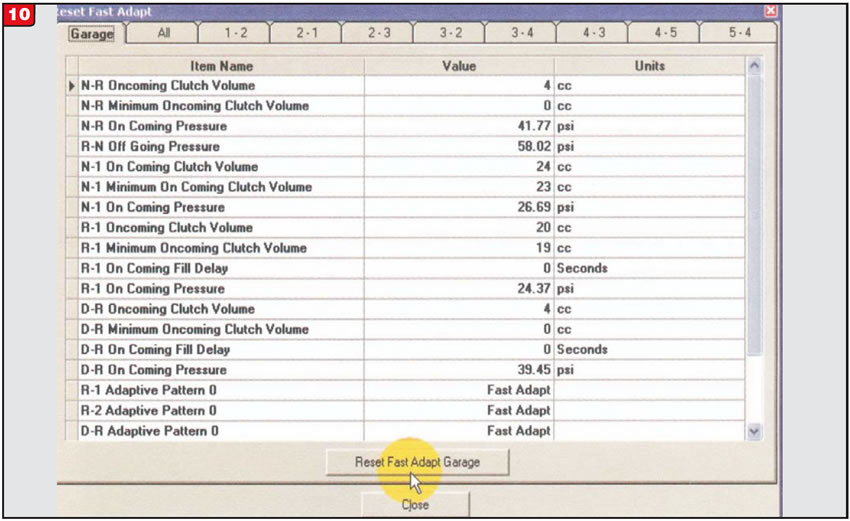

The screen capture in Figure 10 shows an example of shift adaptives.

To help you understand what the adaptive information means, the following categories as displayed on the scan tool are:

VALUE: The number of units being provided for a particular shift

UNITS: The type of measurement for a given value ONCOMING

CLUTCH VOLUME: Indicates the total amount of fluid being used to apply the shift’s oncoming clutch

MINIMUM ONCOMING CLUTCH: Indicates the minimum amount of fluid being used to apply an oncoming clutch

ONCOMING PRESSURE: Indicates the hydraulic pressure being applied to the shift’s oncoming clutch

OFF GOING PRESSURE: Indicates the hydraulic pressure remaining in the shift’s off-going clutch-apply circuit.

ONCOMING FILL DELAY: Indicates the lag time between when the clutch is commanded on by the TCM vs. actual clutch-apply time.

ADAPTIVE PATTERN: Indicates the current adaptive logic used by the TCM – fast or slow.

October 2012 Issue

Volume 29, No. 10

- Saturn VT25E CVT

- Belt slippage Saturn VT25E CVT

- Case damage Allison 1000/2000: Code P0562

- Allison LCT1000: Resetting shift adapts