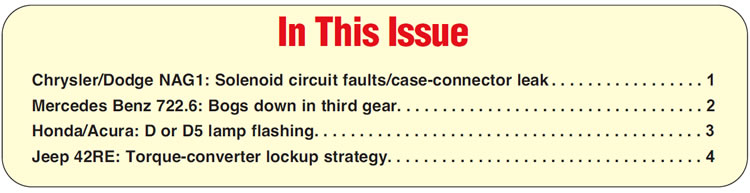

Some 2004 and up Chrysler/Dodge vehicles equipped with the NAG 1 transmission may exhibit intermittent solenoid-circuit fault codes along with a leak at the case-connector area of the transmission (Figure 1).

The cause may be faulty O-rings on the adapter sleeve allowing the transmission fluid to cause connection problems, resulting in the intermittent trouble codes.

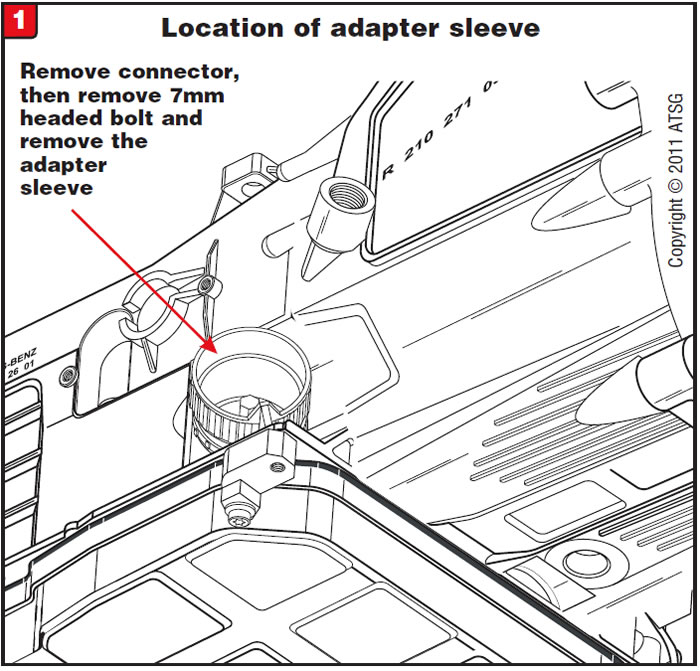

Replace the adapter sleeve and connector (Figure 2) with the updated part number listed in service information. Verify that all solenoids ohm-test correctly as shown in the chart in Figure 2.

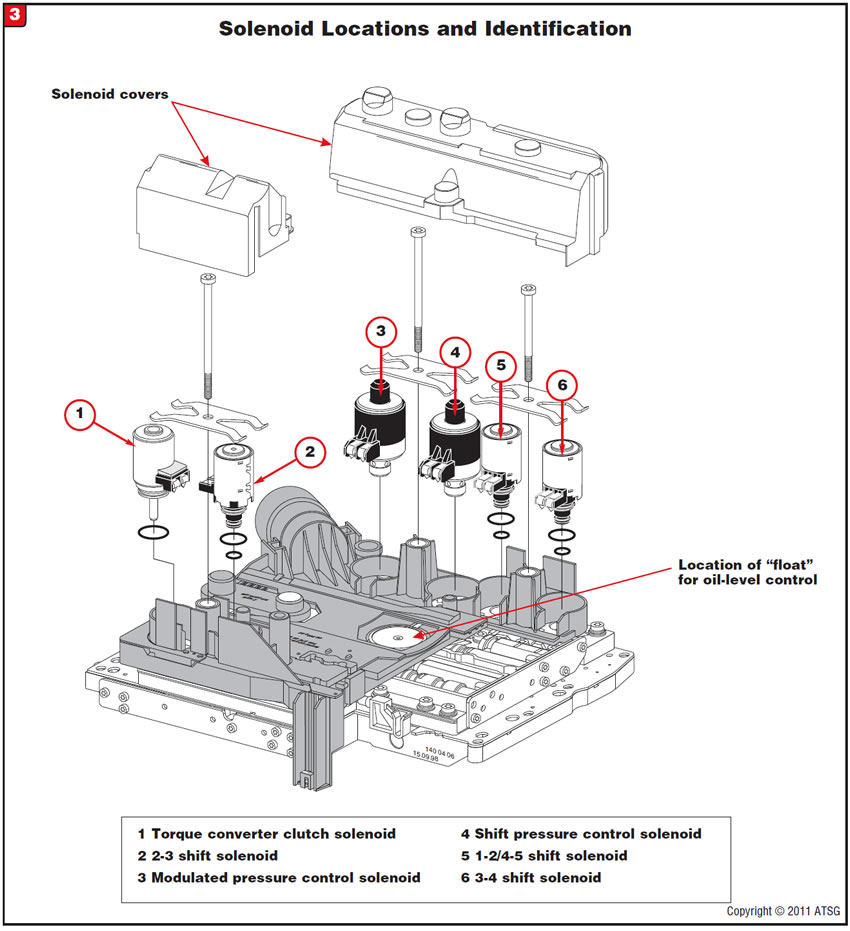

Refer to Figure 3 for the location of the solenoids on top of the valve body, and replace as necessary.

- Adapter-sleeve and connector kit. . . . . . . . . . . 68021352AA

- (Includes connector 5120265AA)

Note: This connector is also available individually at many aftermarket suppliers.

After overhaul, the transmission bogs down as it completes the shift into third. A slipping condition may also exist. After a few attempts to shift into third gear, the transmission will go to failsafe.

When the transmission was removed and disassembled, the technician found that the K2 friction plates had cut through the aluminum rear-carrier hub.

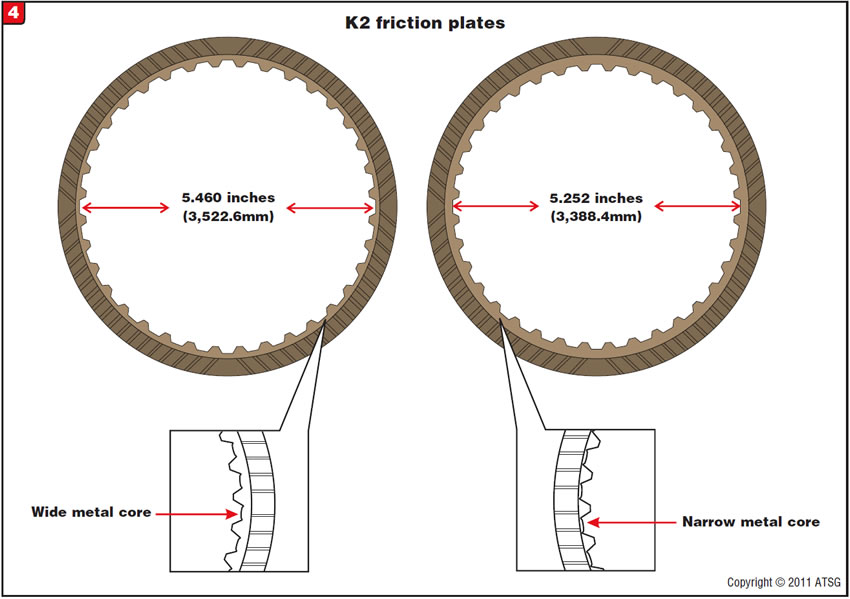

There are two different inside diameters for the K2 friction plates (Figure 4). The outside diameters and tooth configurations are the same for both, and both have 36 internal teeth.

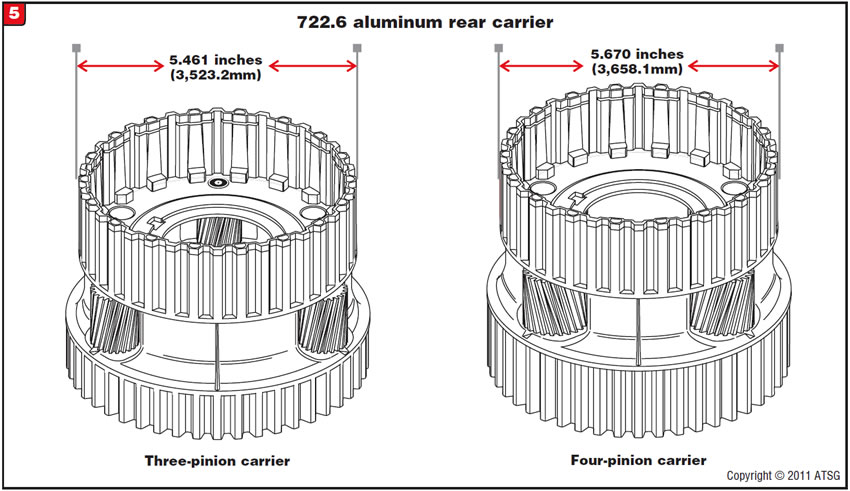

There are two different diameters for the rear-carrier hubs to accommodate the difference in the K2 friction plates (Figure 5). These differences are dependent on engine size.

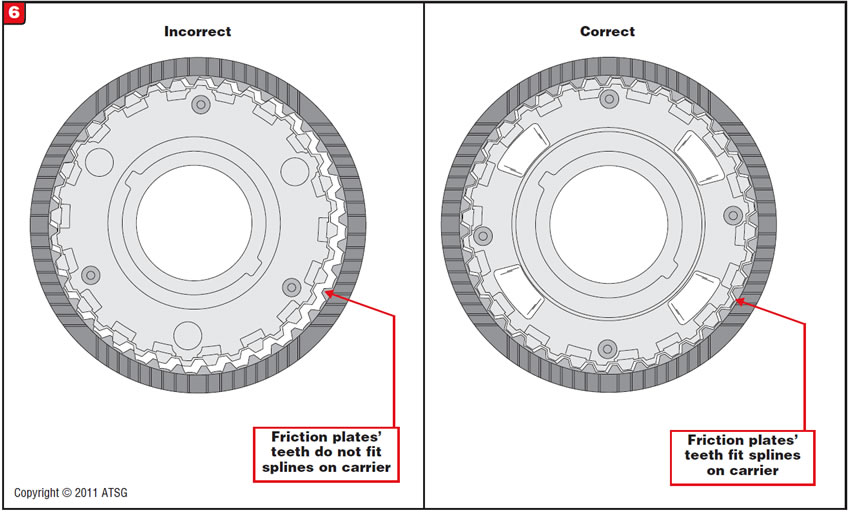

When the frictions with larger inside diameters are installed on the smaller-diameter carrier, the teeth of the K2 friction plates will spin around on the aluminum carrier hub and cut into it. Figure 6 illustrates the correct and incorrect tooth-to-spline fits of the K2 friction plates to the carrier-hub splines.

The smaller-diameter carrier is easily identified because it is a three-pinion design; the larger-diameter carrier is a four-pinion design.

Ensure that there is a proper fit between the teeth of the K2 friction plate and the splines of the carrier hub.

The vehicle comes in with the D5 lamp flashing, but when the technician scans the PCM for codes he finds none. The vehicle may have symptoms indicating that there is a transmission problem and the technician knows that when the D5 Lamp is flashing there should be a code present.

Some aftermarket scan tools do not have the ability to display trouble codes under certain conditions.

Even though these vehicles are OBD-II compliant and five-digit codes should be present, in instances such as this flash codes can still be retrieved via a flashing D5 lamp.

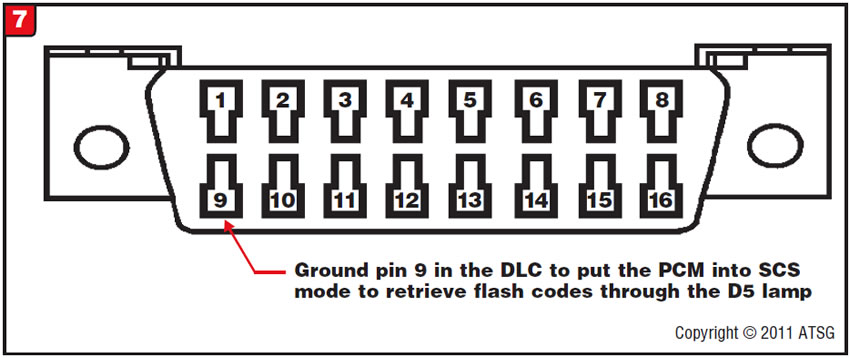

Locate the OBD-II data link connector (DLC) (Figure 7) and ground terminal 9 (in most instances this should be a brown wire). This action will put the PCM in Service Check Signal (SCS) mode and the D5 lamp will now flash code patterns. The long flashes are the first digit of the code and the first digit of the code and the short flashes are the second digit. If a single-digit code is stored, it will be all short flashes.

The MIL lamp may be illuminated; if so, engine codes will always be displayed first.

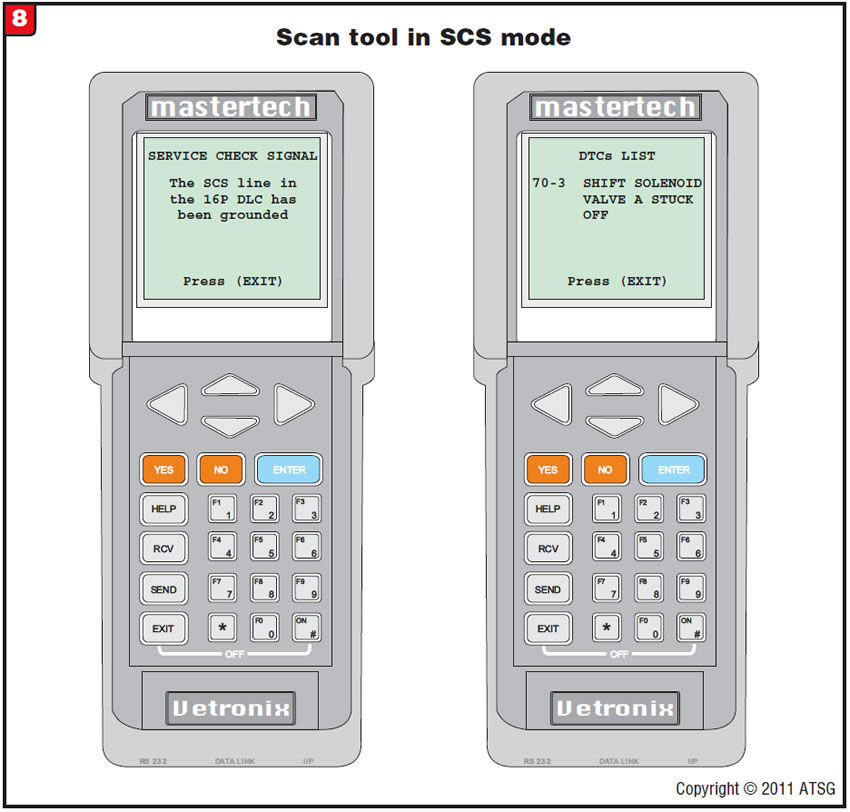

Note: Some scan tools have the ability to put the PCM into SCS mode by grounding DLC terminal 9 through the scan tool. The scan tool will now display the two-digit trouble code as well as a third digit that indicates the nature of the failure (Figure 8), such as a circuit high or circuit low fault.

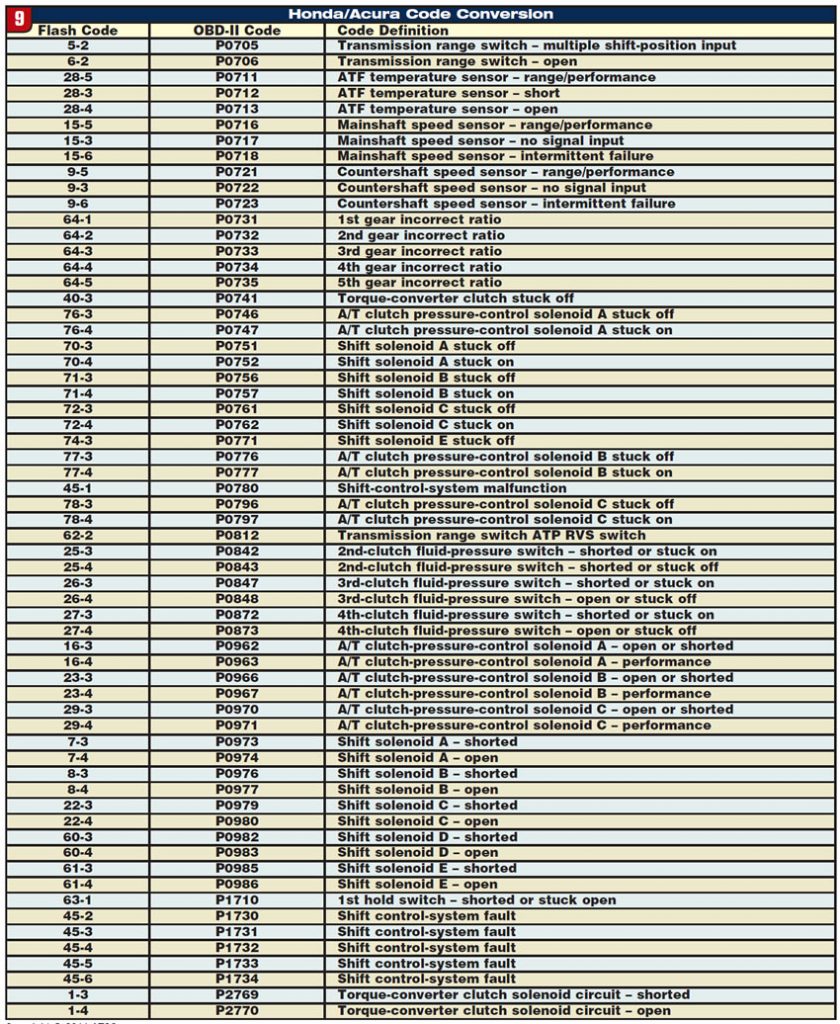

The chart in Figure 9 shows the conversion from the OBD-II codes to the SCS flash codes.

A 2004 Jeep Grand Cherokee equipped with 4.0-liter engine and 42RE transmission may have a complaint of a late lockup application. When you’re checking the signal to apply lockup the scan tool indicates that the late lockup application is being commanded.

These vehicles were selectively reprogrammed with a converter-lockup strategy that will not allow lockup application until vehicle speed is greater than 48 mph (77 km/h) and the transmission is in fourth gear. When overdrive is canceled, lockup application will occur at a vehicle speed greater than 29 mph (47 km/h). The difference in engine speed when lockup is enabled is about 300 rpm.

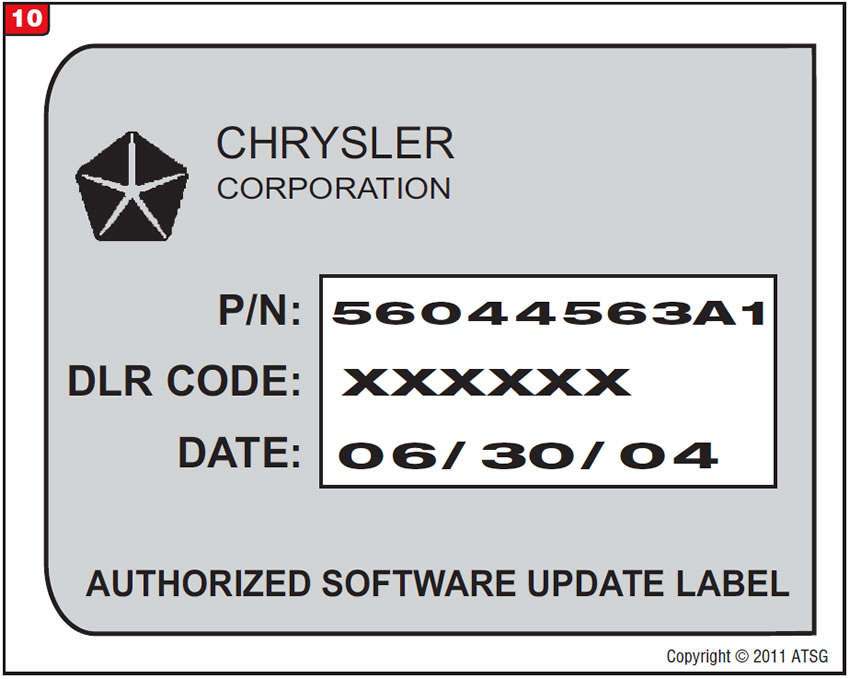

There is no correction; this reflash was done to enhance vehicle performance (Figure 10).

- Torque-converter lockup-enable feature software version. . . . . . 56044563A1

October 2011 Issue

Volume 28, No. 10

- Chrysler/Dodge NAG1: Solenoid circuit faults/case-connector leak

- Mercedes Benz 722.6: Bogs down in third gear

- Honda/Acura: D or D5 lamp flashing

- Jeep 42RE: Torque-converter lockup strategy