Technically Speaking

- Subject: Damage to rear planetary gears resulting from no lubrication

- Unit: JR403-E

- Vehicle Application: 1995 Isuzu NPR

- Essential Reading: Rebuilder, Diagnostician

- Author: Wayne Colonna, ATSG, Transmission Digest Technical Editor

A JR403-E transmission from a 1995 Isuzu NPR came in over the counter to Luis Zabala’s transmission shop in Miami for repair of a front-seal leak. The unit was examined for damage because of the possibility of low-fluid-level conditions. The only wear or damage discovered was the pump bushing and seal.

So the repair to the pump was made, and the owner picked up the transmission. It was recommended that he replace the crankshaft hub so as to better support the torque converter, preventing repeat failure, and the owner agreed to do so. Fifty miles later the transmission was back in Luis’s shop with the rear planets totally cooked. It was repaired and given back to the owner with strong recommendations to flush or replace the cooler. The owner agreed, yet 50 miles later the transmission failed again.

This time the vehicle was brought into the shop (Figure 1) and the transmission was removed, and the problem of rear-planetary melt-down was verified.

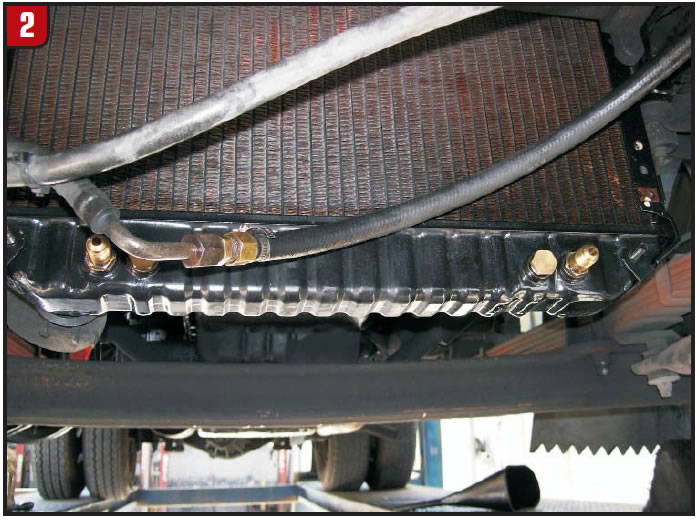

Upon vehicle inspection, it was discovered that a new radiator (Figure 2) and a new auxiliary filter by the frame rail had been installed (Figure 3).

After the unit was repaired and placed back into the vehicle, the front cooling line was removed by the auxiliary-filter manifold, where good cooler flow was verified. This check was then repeated by the radiator, where it was found that there was absolutely no cooler flow. This pointed to a problem with the auxiliary filter, so another new filter was installed – still with no positive results. There was still no cooler flow at the radiator.

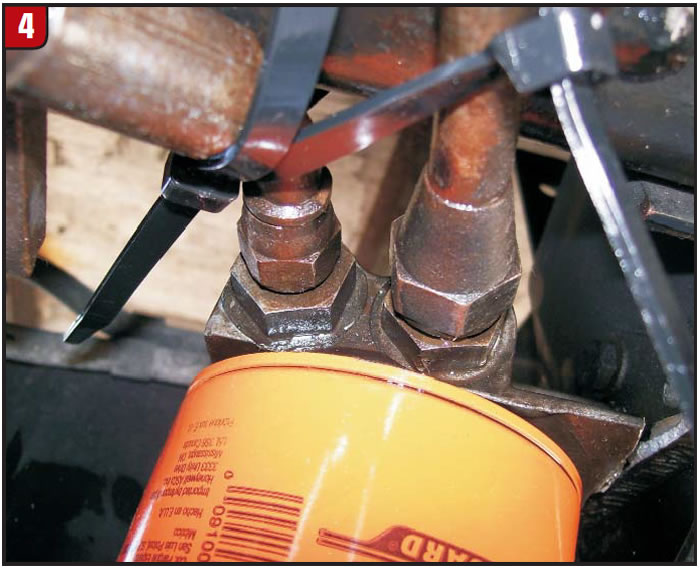

When looking at the filter manifold, you can see that the cooling line from the front fitting on the transmission and the line from the manifold to the radiator cannot be cross-connected, as the fittings are two different sizes. However, the fittings on the manifold can be removed and switched (Figure 4). This would allow cooler flow from the transmission to enter the auxiliary filter in the opposite direction. And this is what Luis did, and it worked; he had cooler flow all the way to the radiator.

Further discussions with Mike Riley from Transtar Industries and Luis revealed that this auxiliary-filter setup is not original from the factory. It is when the vehicle goes to the dealer for repairs that this auxiliary-filter kit is installed. And apparently, this auxiliary transmission filter is not available in just any local parts store. What you do get is a typical one-way-checkvalve engine-oil filter that just happens to flow in the opposite direction of this cooling circuit. Quite an expensive lesson to learn, especially when the right filter costs only $9 and prevents the problem of no rear lubrication.

Parts information received from www.isuzutruckparts.com, 800-338-9249

1988-98 Isuzu NPR diesel auxiliary transmission filter part # 97182282