Technically Speaking®

- Author: Wayne Colonna

- Subject Matter: 6L80/90

- Issue: Output shaft

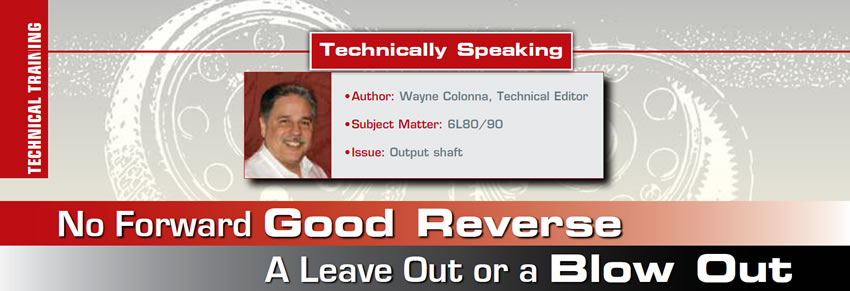

During model year 2012, GM and GMC trucks equipped with the 6L80/90 transmission received an updated output shaft assembly. The previous output shaft assembly was comprised of a separate output shaft, output carrier ring gear, ring gear spacer, output carrier internal front gear and snap rings as seen in Figure 1 left-hand side.

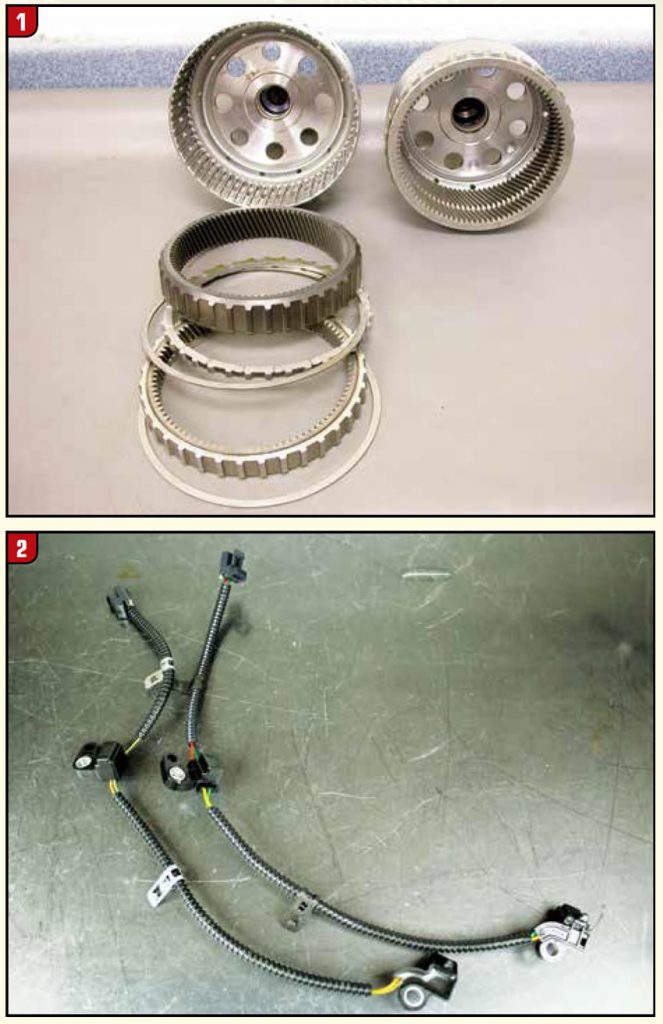

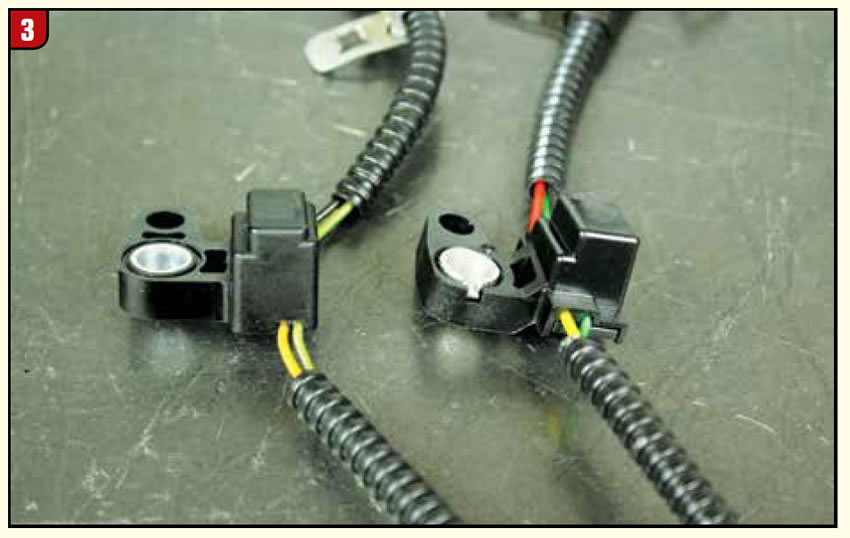

The updated output shaft assembly known as the “UNIGEAR” is now all one piece. All components of the previous design are now an integral part of the output shaft as shown in Figure 1 right-hand side. This output shaft assembly required the use of a different style input and output transmission speed sensor assembly shown in figures 2 and 3.

The “UNIGEAR” output shaft assembly will back service all 6L80/90 transmissions as long as the “stepped” output speed sensor assembly is used. Using the previously designed output speed sensor assembly with the “UNIGEAR” output shaft assembly will result in immediate damage to the output speed sensor. Using the new “stepped” output shaft assembly with the previous output shaft will cause too much of an air gap which will result in a DTC being set.

There have been reports in the field that a garage shift from reverse to drive produces a “snapping” sound, which has been traced to a defect with the previous design output shaft assembly. Installing the “UNIGEAR” output shaft assembly seemed to have eliminated the garage shift noise.

There are wide ranges of output shafts due to the variety of vehicle configurations these transmissions find themselves in. This means if a UNIGEAR assembly is needed, it must be ordered by the VIN to obtain the correct application. The previous output shaft assembly does disassemble as seen in Figure 1 left side. Shops have been known to modify these assemblies to fit whatever configuration is needed. For example, a shop in Illinois modified an output shaft assembly to fit an early transfer case for a 6L50 2006 Cadillac CTX. It originally came in with a stripped output shaft. A machine shop modified an output shaft that would fit in this application.

When they were done, the vehicle had reverse but no forward. They changed the controller, which didn’t resolve the issue. They pulled the transmission and went through it again and couldn’t see anything wrong. They changed the valve body and still it had not forward yet good reverse. Once again the unit came out and a different tech went through it. With Max having fresh eyes on the transmission, he discovered the problem. Take a look at Figure 4 carefully. Do you see anything wrong? The rear internal ring gear is missing! The front sun gear and ring gear is used for reverse. The rear sun gear and ring gear is used for first, second, third and fourth. Without that rear internal ring gear there is no forward movement. Many thanks go to Max Dease from Kings Transmissions willing to share this unfortunate experience with us.

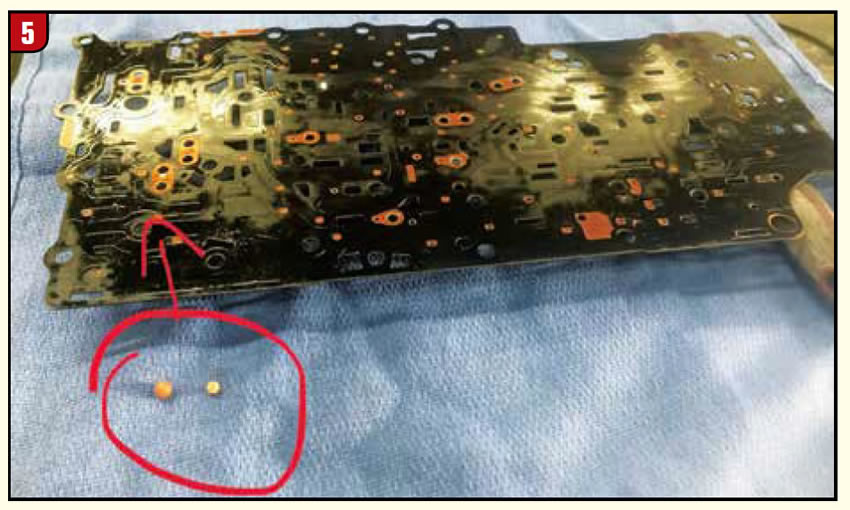

Interestingly enough, Lorenzo Ortiz from Phillips Transmissions had a 2016 6L80 come into his shop with a no forward but good reverse complaint from the customer. The vehicle had 123K on it so it has seen better days. Since the output shaft would be a UNIGEAR version and no one else has recently worked on the transmission, the valve body came out for inspection. What Lorenzo discovered was the #1 checkball had reduced in size so considerably (Figure 5) that it allowed Drive 1-6 oil to dump to exhaust. That’s will indeed cause a no move forward. Two different reasons producing the same complaint all in one day: A leave out or a blow out.